Biodegradable polymers break down naturally through microbial activity into water, carbon dioxide, and biomass, but their decomposition rate and environmental impact vary based on conditions. Compostable polymers degrade within a defined timeframe under industrial composting conditions, leaving no toxic residues, ensuring a more controlled and eco-friendly disposal process. Selecting between these polymers depends on the intended application, disposal infrastructure, and environmental goals for sustainable materials engineering.

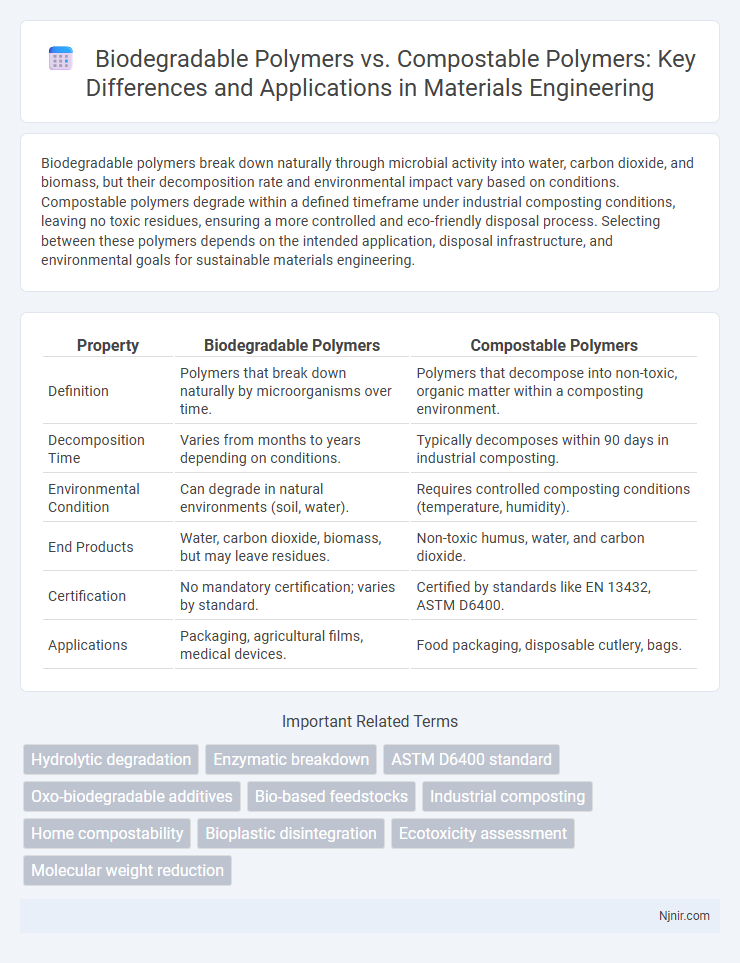

Table of Comparison

| Property | Biodegradable Polymers | Compostable Polymers |

|---|---|---|

| Definition | Polymers that break down naturally by microorganisms over time. | Polymers that decompose into non-toxic, organic matter within a composting environment. |

| Decomposition Time | Varies from months to years depending on conditions. | Typically decomposes within 90 days in industrial composting. |

| Environmental Condition | Can degrade in natural environments (soil, water). | Requires controlled composting conditions (temperature, humidity). |

| End Products | Water, carbon dioxide, biomass, but may leave residues. | Non-toxic humus, water, and carbon dioxide. |

| Certification | No mandatory certification; varies by standard. | Certified by standards like EN 13432, ASTM D6400. |

| Applications | Packaging, agricultural films, medical devices. | Food packaging, disposable cutlery, bags. |

Introduction to Biodegradable and Compostable Polymers

Biodegradable polymers are materials designed to break down naturally through microbial activity, reducing environmental impact by decomposing into water, carbon dioxide, and biomass. Compostable polymers share similar degradation properties but must meet specific standards, such as ASTM D6400 or EN 13432, ensuring they break down within a defined timeframe in industrial composting conditions. Understanding the distinction between general biodegradability and certified compostability is crucial for applications in sustainable packaging and waste management.

Defining Biodegradability and Compostability

Biodegradable polymers are materials that break down into natural substances like water, carbon dioxide, and biomass through microbial activity over a variable time depending on environmental conditions. Compostable polymers must meet specific standards, such as ASTM D6400 or EN 13432, ensuring complete decomposition under industrial composting conditions within a defined period, leaving no toxic residues. The key distinction lies in compostable polymers' ability to degrade efficiently within composting systems versus biodegradable polymers, which may degrade slowly or incompletely in natural environments.

Chemical Structure and Degradation Mechanisms

Biodegradable polymers typically consist of hydrolyzable ester bonds in their backbone, enabling enzymatic cleavage and microbial digestion under various environmental conditions. Compostable polymers are a subset designed to degrade under specific controlled composting conditions, featuring chemical structures that rapidly break down into water, carbon dioxide, and biomass through accelerated microbial activity. The primary distinction lies in the degradation mechanism speed and environment specificity, with compostable polymers requiring industrial composting parameters, whereas biodegradable polymers may degrade more broadly but often at slower rates.

Standards and Certification for Biodegradability and Compostability

Biodegradable polymers are evaluated under standards such as ASTM D5338 and ISO 14855, which measure the polymer's ability to break down into natural elements under controlled composting conditions within a specified timeframe. Compostable polymers meet more stringent criteria outlined in certifications like ASTM D6400 and EN 13432, requiring the material to biodegrade at a rate comparable to organic matter and disintegrate physically without leaving toxic residues. Certification bodies such as TUV Austria and BPI ensure compliance with these standards, verifying environmental safety and performance in industrial or home composting environments.

Material Sources and Synthesis Methods

Biodegradable polymers are derived from both renewable sources such as starch, cellulose, and polylactic acid (PLA) produced via fermentation of biomass, and petrochemical sources like polycaprolactone synthesized through ring-opening polymerization. Compostable polymers, primarily sourced from renewable materials like polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch blends, undergo controlled synthesis methods including microbial fermentation and chemical polymerization tailored to meet industrial compostability standards. Differences in synthesis impact degradation rates and environmental outcomes, with compostable polymers engineered to break down fully in composting conditions, while biodegradable polymers vary widely in decomposition pathways.

Performance Comparison: Mechanical and Thermal Properties

Biodegradable polymers often exhibit variable mechanical strength and thermal stability depending on their chemical composition, with materials like polylactic acid (PLA) showing moderate tensile strength and melting points around 150-170degC. Compostable polymers, designed to break down under specific composting conditions, typically maintain comparable mechanical properties during use but degrade rapidly at elevated temperatures (50-60degC) in industrial composting environments. Performance comparison reveals that while both types offer eco-friendly advantages, compostable polymers generally provide more predictable degradation timelines without significantly compromising mechanical integrity during their functional lifespan.

Environmental Impact and End-of-Life Scenarios

Biodegradable polymers break down through microbial activity into natural substances like water, carbon dioxide, and biomass, but their decomposition rate and environmental impact vary depending on conditions such as temperature, humidity, and presence of microorganisms. Compostable polymers specifically degrade in industrial composting facilities within a defined time frame, converting into nutrient-rich compost without leaving toxic residues, making them more suitable for controlled waste management systems. End-of-life scenarios for biodegradable polymers may result in incomplete degradation or microplastic formation in natural environments, whereas compostable polymers require appropriate composting infrastructure to ensure proper decomposition and environmental benefits.

Industrial and Commercial Applications

Biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are extensively used in industrial packaging, agricultural films, and medical devices due to their ability to break down under specific environmental conditions. Compostable polymers, certified to meet standards like ASTM D6400 or EN 13432, are preferred for food packaging, disposable tableware, and commercial waste management because they decompose into non-toxic components within commercial composting facilities. Industrial applications prioritize the selection based on degradation rate, end-of-life disposal infrastructure, and compatibility with existing recycling or composting systems to optimize sustainability outcomes.

Challenges in Waste Management and Recycling

Biodegradable polymers often require specific environmental conditions such as controlled temperature and humidity to decompose effectively, posing challenges for conventional waste management systems. Compostable polymers, certified to break down in industrial composting facilities within a defined timeframe, face limitations as these facilities are not universally available, leading to contamination and sorting difficulties. Both types complicate recycling processes due to material incompatibility and the risk of degrading the quality of recycled plastics.

Future Trends and Research Directions in Sustainable Polymers

Future trends in sustainable polymers emphasize the development of advanced biodegradable polymers with enhanced mechanical properties and controlled degradation rates for diverse applications, including packaging and medical devices. Research is increasingly focused on compostable polymers derived from renewable biomass, aiming to improve enzymatic breakdown efficiency and compatibility with industrial composting systems to reduce environmental impact. Innovations in polymer blends and bio-based additives are driving the integration of biodegradability and compostability, fostering circular economy models within plastic production and waste management industries.

Hydrolytic degradation

Hydrolytic degradation in biodegradable polymers involves breakdown through water interactions over time, while compostable polymers specifically degrade under controlled composting conditions, yielding non-toxic residues primarily via accelerated hydrolysis processes.

Enzymatic breakdown

Biodegradable polymers undergo enzymatic breakdown into natural byproducts over time, whereas compostable polymers require specific enzymatic conditions in industrial composting facilities to fully decompose.

ASTM D6400 standard

ASTM D6400 standard defines compostable polymers as materials that biodegrade in industrial composting conditions within 180 days, distinguishing them from biodegradable polymers that may degrade under broader environments without specific time or compostability guarantees.

Oxo-biodegradable additives

Oxo-biodegradable additives accelerate the fragmentation of biodegradable polymers into microplastics without ensuring complete compostability, unlike compostable polymers that fully break down into non-toxic components under controlled conditions.

Bio-based feedstocks

Bio-based feedstocks for biodegradable polymers derive from renewable resources but may not fully break down like compostable polymers, which require specific conditions to decompose into non-toxic biomass.

Industrial composting

Industrial composting requires compostable polymers that fully break down under high heat and controlled conditions, whereas biodegradable polymers may degrade more slowly and incompletely in such environments.

Home compostability

Home compostable polymers break down safely in residential compost settings within months, while biodegradable polymers may require industrial conditions and longer times, making home compostability a key advantage for eco-friendly waste management.

Bioplastic disintegration

Biodegradable polymers degrade through microbial activity into natural elements under various environmental conditions, while compostable polymers specifically disintegrate into non-toxic residues within a defined composting timeframe, ensuring complete bioplastic disintegration without harmful residues.

Ecotoxicity assessment

Ecotoxicity assessment of biodegradable polymers reveals varied environmental impacts compared to compostable polymers, with compostable variants typically demonstrating reduced toxicity and faster degradation in controlled composting environments.

Molecular weight reduction

Biodegradable polymers undergo molecular weight reduction through enzymatic hydrolysis breaking down polymer chains into smaller molecules, whereas compostable polymers require this molecular weight reduction to achieve complete decomposition under specific composting conditions.

Biodegradable polymers vs Compostable polymers Infographic

njnir.com

njnir.com