Powder metallurgy offers superior control over material properties and microstructure compared to casting, enabling the production of components with precise dimensional tolerances and enhanced mechanical performance. Unlike casting, powder metallurgy minimizes defects such as porosity and shrinkage, resulting in improved strength and wear resistance. This process also allows for the fabrication of complex geometries and the efficient use of raw materials, reducing waste and production costs.

Table of Comparison

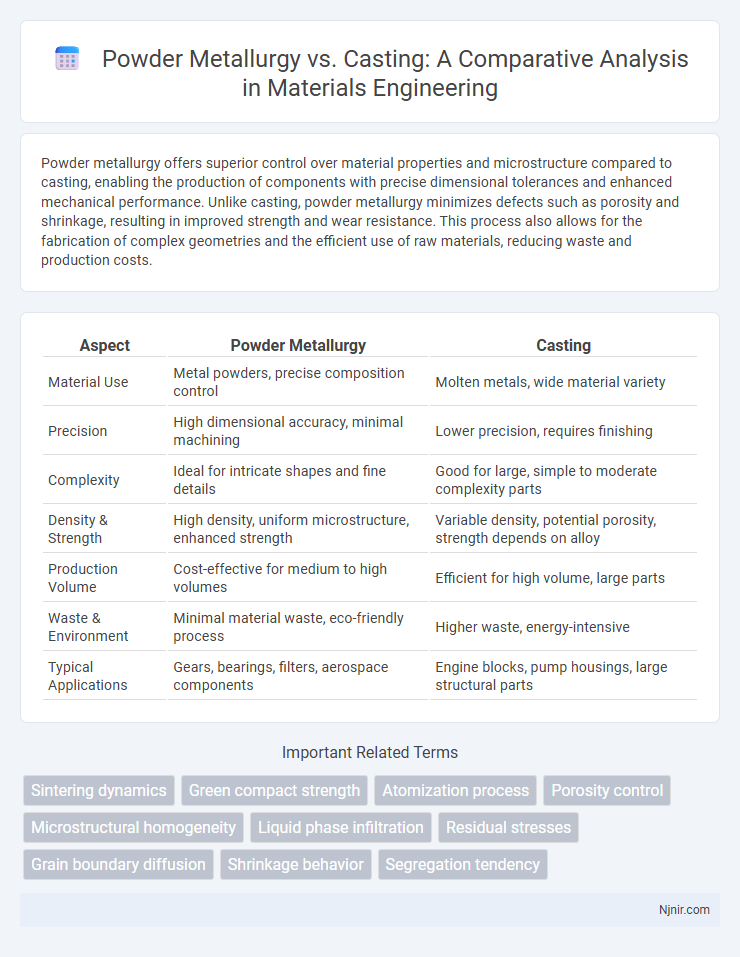

| Aspect | Powder Metallurgy | Casting |

|---|---|---|

| Material Use | Metal powders, precise composition control | Molten metals, wide material variety |

| Precision | High dimensional accuracy, minimal machining | Lower precision, requires finishing |

| Complexity | Ideal for intricate shapes and fine details | Good for large, simple to moderate complexity parts |

| Density & Strength | High density, uniform microstructure, enhanced strength | Variable density, potential porosity, strength depends on alloy |

| Production Volume | Cost-effective for medium to high volumes | Efficient for high volume, large parts |

| Waste & Environment | Minimal material waste, eco-friendly process | Higher waste, energy-intensive |

| Typical Applications | Gears, bearings, filters, aerospace components | Engine blocks, pump housings, large structural parts |

Introduction to Powder Metallurgy and Casting

Powder metallurgy involves producing metal components by compacting fine metal powders and sintering them at high temperatures, enabling precise control of material properties and minimal waste. Casting is a manufacturing process where molten metal is poured into a mold, solidifying into the desired shape, ideal for complex geometries and large parts. Both methods offer unique advantages depending on the application, material requirements, and production scale.

Fundamental Principles of Powder Metallurgy

Powder metallurgy involves producing metal parts by compacting fine metal powders into desired shapes and sintering them at high temperatures below melting points, preserving material properties and reducing waste. This process allows precise control of microstructure and porosity, leading to enhanced mechanical strength and tailored material characteristics not easily achievable through casting. Unlike casting, which relies on melting and solidifying metals, powder metallurgy offers superior dimensional accuracy and material utilization for complex and high-performance components.

Overview of Casting Techniques

Casting techniques primarily involve pouring molten metal into molds to form desired shapes, with common methods including sand casting, die casting, and investment casting. These processes allow for the production of complex geometries and large components with relatively low tooling costs. Compared to powder metallurgy, casting can achieve faster production rates but may result in coarser microstructures and less precise dimensional control.

Material Selection Criteria

Powder metallurgy offers precise control over material composition and microstructure, enabling the selection of alloys with superior wear resistance, high strength, and complex geometries that may be challenging for casting processes. Casting is generally preferred for materials requiring excellent fluidity, such as aluminum and cast iron, where homogeneity and the capability to produce large, intricate shapes at lower costs are essential. Selection criteria should consider mechanical properties, dimensional tolerances, production volume, and the specific application's thermal and corrosion resistance requirements to determine the optimal manufacturing method.

Process Steps and Workflow Comparison

Powder metallurgy involves blending metal powders, compacting them into a desired shape, and sintering at high temperatures to bond particles, enabling precise control over material properties and minimal waste. Casting requires melting metal, pouring it into molds, and solidifying to form complex shapes, with subsequent cooling and finishing steps prone to defects like porosity and shrinkage. The workflow of powder metallurgy emphasizes powder preparation and controlled sintering, while casting centers on molten metal handling and mold design for shape accuracy.

Microstructure and Mechanical Properties

Powder metallurgy produces components with a fine, uniform microstructure due to controlled particle size and sintering processes, leading to enhanced mechanical properties such as higher strength and wear resistance compared to casting. Casting often results in coarser microstructures with dendritic grain formations that can introduce porosity and segregation, reducing mechanical homogeneity and toughness. The precise control over alloy composition and minimal grain growth in powder metallurgy yields superior fatigue resistance and dimensional accuracy compared to traditional casting methods.

Design Flexibility and Geometrical Complexity

Powder metallurgy offers superior design flexibility by enabling the production of intricate geometries with tight tolerances and minimal material waste, which is challenging to achieve through traditional casting methods. The process supports the creation of complex internal features and porous structures that casting cannot easily replicate due to mold limitations and solidification constraints. This advantage makes powder metallurgy ideal for applications requiring lightweight components with optimized shapes and enhanced mechanical properties.

Cost Analysis and Production Efficiency

Powder metallurgy offers lower material waste and reduced machining costs compared to casting, leading to overall cost savings in high-volume production. Casting involves higher initial tooling and mold expenses but can achieve faster production cycles for large, simple parts. Powder metallurgy enhances production efficiency by enabling near-net shape manufacturing and consistent material properties, whereas casting efficiency varies with complexity and cooling rates.

Typical Applications in Industry

Powder metallurgy is widely used in automotive components, aerospace parts, and cutting tools due to its ability to produce precise, complex shapes with high strength and wear resistance. Casting is preferred in heavy machinery, engine blocks, and large structural components where cost-efficiency and the ability to create large, intricate shapes are critical. Both processes serve distinct industrial applications by balancing material properties, manufacturing costs, and design complexity.

Environmental Impact and Sustainability

Powder metallurgy significantly reduces waste by using near-net shape manufacturing, leading to material efficiency rates often exceeding 95%, compared to casting's higher scrap rates and energy-intensive melting processes. The lower energy consumption in powder metallurgy results from operating below melting points, decreasing greenhouse gas emissions relative to casting, which requires extensive fuel and produces more CO2. Recycling is more effective in powder metallurgy since leftover powders and scrap can be reprocessed with minimal environmental footprint, enhancing sustainability over conventional casting methods with limited recyclability.

Sintering dynamics

Powder metallurgy offers enhanced sintering dynamics by enabling precise control over particle size, temperature, and atmosphere, resulting in superior microstructural uniformity and mechanical properties compared to traditional casting methods.

Green compact strength

Powder metallurgy generally produces green compacts with higher uniform strength and density compared to casting, due to controlled particle bonding and minimal porosity.

Atomization process

The atomization process in powder metallurgy produces fine, uniform metal powders by rapidly solidifying molten metal, enabling superior microstructure control and mechanical properties compared to traditional casting methods.

Porosity control

Powder metallurgy offers superior porosity control compared to casting by enabling precise adjustment of particle size and compaction pressure, resulting in enhanced material density and mechanical properties.

Microstructural homogeneity

Powder metallurgy ensures superior microstructural homogeneity compared to casting by producing fine, uniform grains and reducing segregation and porosity inherent in traditional casting processes.

Liquid phase infiltration

Powder metallurgy with liquid phase infiltration enhances mechanical properties and density beyond traditional casting by introducing a metal alloy infiltrant into a porous powder compact.

Residual stresses

Powder metallurgy typically results in lower residual stresses compared to casting due to its near-net shape fabrication and controlled sintering processes that minimize thermal gradients.

Grain boundary diffusion

Powder metallurgy enhances grain boundary diffusion by creating finer microstructures compared to casting, resulting in improved mechanical properties and increased material strength.

Shrinkage behavior

Powder metallurgy exhibits significantly lower shrinkage rates, typically around 1-2%, compared to casting processes, which can experience shrinkage levels exceeding 5%, resulting in improved dimensional accuracy and reduced post-processing requirements.

Segregation tendency

Powder metallurgy exhibits significantly lower segregation tendency than casting due to its uniform particle mixing and controlled solidification processes.

powder metallurgy vs casting Infographic

njnir.com

njnir.com