Piezoelectric ceramics generate electric charge under mechanical stress, making them ideal for sensors and actuators, while ferroelectric ceramics exhibit spontaneous electric polarization that can be reversed by an external electric field, enabling their use in non-volatile memory devices. The crystal structure of piezoelectric ceramics lacks a center of symmetry, which is essential for their piezoelectric effect, whereas ferroelectric ceramics possess domains that switch polarization states, contributing to their unique dielectric and ferroelectric properties. Material selection depends on application requirements, with piezoelectric ceramics favored for energy conversion and ferroelectric ceramics preferred for memory storage and tunable capacitors.

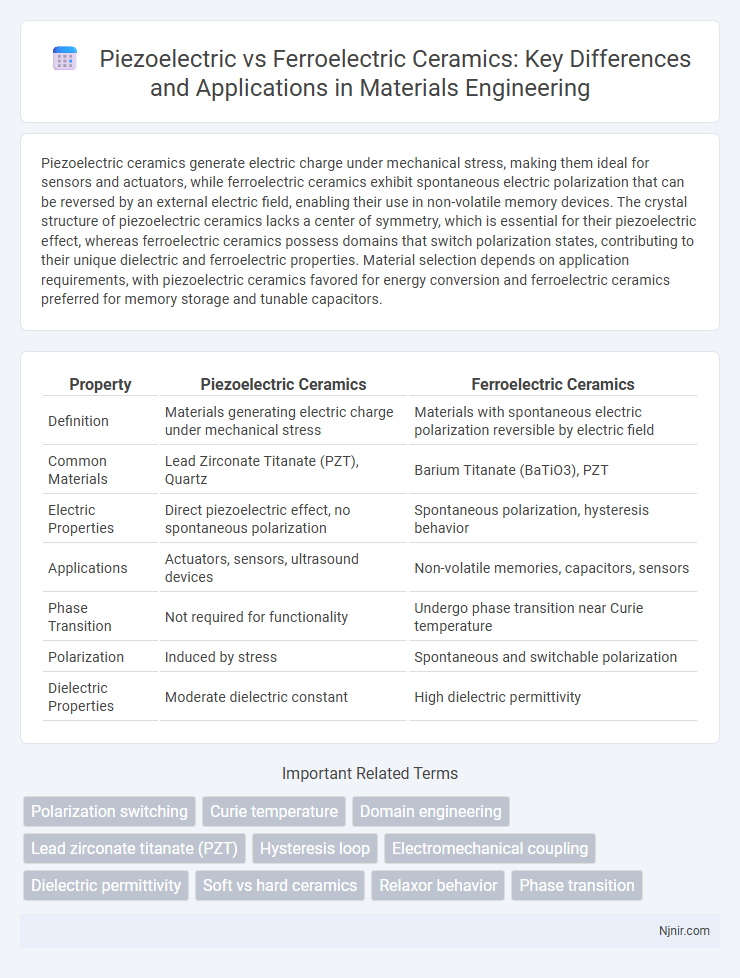

Table of Comparison

| Property | Piezoelectric Ceramics | Ferroelectric Ceramics |

|---|---|---|

| Definition | Materials generating electric charge under mechanical stress | Materials with spontaneous electric polarization reversible by electric field |

| Common Materials | Lead Zirconate Titanate (PZT), Quartz | Barium Titanate (BaTiO3), PZT |

| Electric Properties | Direct piezoelectric effect, no spontaneous polarization | Spontaneous polarization, hysteresis behavior |

| Applications | Actuators, sensors, ultrasound devices | Non-volatile memories, capacitors, sensors |

| Phase Transition | Not required for functionality | Undergo phase transition near Curie temperature |

| Polarization | Induced by stress | Spontaneous and switchable polarization |

| Dielectric Properties | Moderate dielectric constant | High dielectric permittivity |

Introduction to Piezoelectric and Ferroelectric Ceramics

Piezoelectric ceramics generate electric charge in response to mechanical stress, making them essential in sensors and actuators, while ferroelectric ceramics possess spontaneous polarization that can be reversed by an external electric field, key for non-volatile memory and capacitors. Both materials share perovskite crystal structures, such as lead zirconate titanate (PZT), enabling their unique electromechanical properties. Understanding the distinctions in polarization behavior and domain dynamics is crucial for optimizing piezoelectric and ferroelectric ceramic applications in electronics and energy harvesting.

Fundamental Principles: Piezoelectricity vs. Ferroelectricity

Piezoelectric ceramics generate electric charge in response to mechanical stress due to their non-centrosymmetric crystal structure, enabling direct electromechanical energy conversion. Ferroelectric ceramics exhibit spontaneous electric polarization that can be reversed by an external electric field, a property arising from asymmetric ion displacement in their crystal lattice. While all ferroelectric materials are piezoelectric, ferroelectric ceramics possess switchable polarization domains, distinguishing them by their hysteresis and memory effects.

Crystal Structure Differences

Piezoelectric ceramics typically exhibit a non-centrosymmetric crystal structure, such as the perovskite-type structure found in lead zirconate titanate (PZT), allowing them to generate electric charge under mechanical stress. Ferroelectric ceramics share a similar perovskite crystal lattice but possess a spontaneous electric polarization that can be reversed by an external electric field, a characteristic absent in non-ferroelectric piezoelectrics. The distinction lies in the presence of switchable dipole moments in ferroelectric ceramics, resulting from a non-centrosymmetric tetragonal or rhombohedral phase, which governs their unique electrical properties compared to purely piezoelectric materials.

Composition and Material Systems

Piezoelectric ceramics commonly consist of lead zirconate titanate (PZT) and barium titanate, recognized for their strong electromechanical coupling and stability. Ferroelectric ceramics primarily include perovskite-structured materials such as PZT and barium titanate, characterized by spontaneous polarization reversible under an electric field. Both material systems share similar compositions, but ferroelectric ceramics exhibit inherent dipole alignment critical for memory and sensing applications.

Mechanisms of Polarization and Responsiveness

Piezoelectric ceramics generate polarization through mechanical stress-induced displacement of ions, resulting in a linear electrical response to applied forces. Ferroelectric ceramics exhibit spontaneous polarization that can be reoriented by an external electric field, producing a nonlinear, hysteresis-driven response crucial for memory and sensor applications. The mechanisms in ferroelectrics involve domain switching and dipole alignment, while piezoelectrics rely primarily on elastic strain-induced charge separation.

Key Properties and Performance Metrics

Piezoelectric ceramics exhibit high electromechanical coupling coefficients and strong voltage generation under mechanical stress, making them ideal for sensors and actuators, whereas ferroelectric ceramics possess spontaneous polarization with reversible dipole orientation under electric fields, essential for non-volatile memory and tunable capacitors. The dielectric constant and coercive field are critical performance metrics for ferroelectric ceramics, influencing their polarization switching behavior and fatigue resistance. Piezoelectric ceramics emphasize mechanical quality factor and piezoelectric charge coefficient (d33) to optimize energy conversion efficiency and sensitivity in precision applications.

Typical Applications and Industry Usage

Piezoelectric ceramics are widely used in sensors, actuators, ultrasonic transducers, and energy harvesting devices due to their ability to convert mechanical stress into electrical signals and vice versa. Ferroelectric ceramics find extensive application in non-volatile memory devices (FeRAM), capacitors, and tunable microwave components owing to their spontaneous polarization and high dielectric permittivity. Both materials are essential in automotive systems, medical ultrasound equipment, and consumer electronics, with piezoelectric ceramics favored for precision motion control and ferroelectric ceramics for high-density data storage and capacitive applications.

Synthesis and Processing Techniques

Piezoelectric ceramics are commonly synthesized through solid-state reaction methods involving high-temperature calcination and sintering of oxide powders like lead zirconate titanate (PZT), while ferroelectric ceramics often require precise control over phase purity and grain size achieved via sol-gel or hydrothermal synthesis techniques. Advanced processing of piezoelectric ceramics includes tape casting, hot pressing, and spark plasma sintering to enhance electromechanical properties, whereas ferroelectric ceramics benefit from controlled atmosphere sintering and domain engineering to optimize polarization behavior. Precise dopant incorporation and thermal treatments are critical in both materials to tailor dielectric constants, coercive fields, and piezoelectric coefficients for targeted applications.

Advancements in Smart Ceramics Technology

Advancements in smart ceramics technology have significantly enhanced the performance of piezoelectric ceramics, enabling higher sensitivity and greater energy conversion efficiency for applications in sensors and actuators. Ferroelectric ceramics have seen improvements in domain engineering and tunable dielectric properties, supporting the development of adaptive capacitors and non-volatile memory devices. Emerging nanostructuring techniques and dopant optimization in both piezoelectric and ferroelectric ceramics contribute to increased operational stability and multifunctionality in next-generation electronic components.

Future Prospects and Research Directions

Piezoelectric ceramics are poised for advancements in energy harvesting and nanoscale sensors due to their direct electromechanical coupling, while ferroelectric ceramics offer substantial potential in non-volatile memory and tunable dielectric applications because of their spontaneous polarization. Research is focusing on enhancing the stability, fatigue resistance, and miniaturization of both materials through novel doping strategies and nanostructuring techniques. Future developments emphasize integrating these ceramics into flexible electronics and smart systems, leveraging their unique electrical and mechanical properties for next-generation multifunctional devices.

Polarization switching

Ferroelectric ceramics exhibit reversible polarization switching under an external electric field, enabling memory and non-volatile applications, whereas piezoelectric ceramics primarily rely on fixed polarization without spontaneous switching.

Curie temperature

Piezoelectric ceramics generally have a higher Curie temperature than ferroelectric ceramics, making them more suitable for high-temperature sensor applications.

Domain engineering

Domain engineering in piezoelectric ceramics enhances electromechanical properties by optimizing domain wall motion, while in ferroelectric ceramics it focuses on controlling polarization switching to improve functional performance.

Lead zirconate titanate (PZT)

Lead zirconate titanate (PZT) is a ferroelectric ceramic widely used for its superior piezoelectric properties, enabling efficient conversion between mechanical and electrical energy in sensors and actuators.

Hysteresis loop

Piezoelectric ceramics exhibit narrow hysteresis loops indicating low energy loss and high linearity, whereas ferroelectric ceramics display wider hysteresis loops signifying strong polarization switching and higher energy dissipation.

Electromechanical coupling

Piezoelectric ceramics exhibit strong electromechanical coupling by converting mechanical stress into electrical charge efficiently, whereas ferroelectric ceramics possess spontaneous polarization enabling reversible electromechanical interaction under an external electric field.

Dielectric permittivity

Piezoelectric ceramics generally exhibit lower dielectric permittivity compared to ferroelectric ceramics due to their differences in crystal structure and polarization mechanisms.

Soft vs hard ceramics

Soft piezoelectric ceramics exhibit high piezoelectric coefficients and low mechanical quality factors ideal for sensors, while hard ferroelectric ceramics possess lower piezoelectric responses but enhanced mechanical quality factors for actuator durability.

Relaxor behavior

Relaxor ferroelectric ceramics exhibit diffuse phase transitions and frequency-dependent dielectric properties, contrasting with conventional piezoelectric ceramics that show sharp phase transitions and stable dielectric responses.

Phase transition

Phase transition in piezoelectric ceramics typically involves a shift from a paraelectric to ferroelectric phase, whereas ferroelectric ceramics exhibit distinct phase transitions between ferroelectric, antiferroelectric, and paraelectric phases critical for their polarization and piezoelectric properties.

piezoelectric ceramics vs ferroelectric ceramics Infographic

njnir.com

njnir.com