Shape memory alloys exhibit the ability to return to a pre-defined shape when heated above their transformation temperature, making them ideal for applications requiring thermal actuation. Pseudoelastic alloys, on the other hand, demonstrate superelastic behavior at a constant temperature, allowing them to undergo significant strains and immediately recover their original shape upon unloading. The distinct phase transformation mechanisms between shape memory and pseudoelastic alloys enable tailored performance in fields such as biomedical devices, aerospace components, and adaptive structures.

Table of Comparison

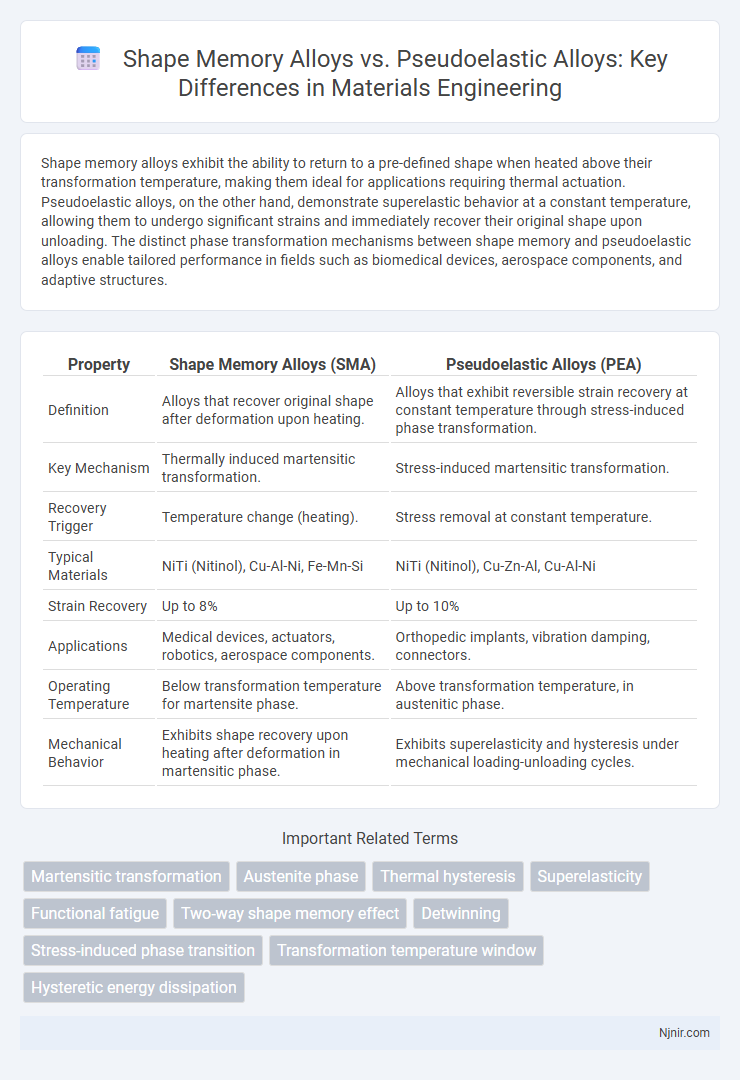

| Property | Shape Memory Alloys (SMA) | Pseudoelastic Alloys (PEA) |

|---|---|---|

| Definition | Alloys that recover original shape after deformation upon heating. | Alloys that exhibit reversible strain recovery at constant temperature through stress-induced phase transformation. |

| Key Mechanism | Thermally induced martensitic transformation. | Stress-induced martensitic transformation. |

| Recovery Trigger | Temperature change (heating). | Stress removal at constant temperature. |

| Typical Materials | NiTi (Nitinol), Cu-Al-Ni, Fe-Mn-Si | NiTi (Nitinol), Cu-Zn-Al, Cu-Al-Ni |

| Strain Recovery | Up to 8% | Up to 10% |

| Applications | Medical devices, actuators, robotics, aerospace components. | Orthopedic implants, vibration damping, connectors. |

| Operating Temperature | Below transformation temperature for martensite phase. | Above transformation temperature, in austenitic phase. |

| Mechanical Behavior | Exhibits shape recovery upon heating after deformation in martensitic phase. | Exhibits superelasticity and hysteresis under mechanical loading-unloading cycles. |

Introduction to Shape Memory and Pseudoelastic Alloys

Shape memory alloys (SMAs) are metal alloys that can return to a predetermined shape when heated after being deformed, relying on a reversible martensitic phase transformation. Pseudoelastic alloys exhibit large, recoverable strains at constant temperature due to stress-induced phase transformation and revert to their original shape upon unloading. Both materials find critical applications in aerospace, biomedical devices, and actuators due to their unique mechanical and thermal properties.

Fundamental Principles and Mechanisms

Shape memory alloys (SMAs) rely on a thermally induced phase transformation between martensite and austenite phases, enabling them to recover a predefined shape upon heating. Pseudoelastic alloys, also known as superelastic alloys, exhibit stress-induced phase transformation at temperatures above the austenite finish temperature, allowing large strains to be recovered immediately upon unloading. Both mechanisms depend on the reversible martensitic transformation but differ fundamentally in their activation triggers: temperature change for SMAs and mechanical stress for pseudoelastic alloys.

Microstructural Differences

Shape memory alloys (SMAs) exhibit a reversible martensitic transformation characterized by a well-defined change in crystal structure between austenite and martensite phases, enabling shape recovery upon heating. Pseudoelastic alloys, often a subset of SMAs, demonstrate stress-induced martensitic transformations at constant temperature, with microstructures rapidly switching between phases under mechanical load. The microstructural differences lie in the stability and transformation mechanisms: SMAs undergo thermally-driven transformations with distinct phase stability, while pseudoelastic alloys rely on stress as a driving force, producing a highly reversible, transient martensitic microstructure.

Phase Transformations: Martensitic vs. Austenitic

Shape memory alloys undergo phase transformations primarily between martensitic and austenitic phases, where the martensitic phase allows deformation and the austenitic phase enables shape recovery upon heating. Pseudoelastic alloys exhibit reversible phase transformations at a constant temperature, switching between austenitic and stress-induced martensitic phases under mechanical loading and unloading without permanent deformation. The martensitic transformation in shape memory alloys is thermally activated, whereas pseudoelasticity relies on stress-induced phase changes within the austenitic temperature range.

Mechanical Properties Comparison

Shape memory alloys (SMAs) exhibit superelasticity and the ability to recover large strains up to 8%, while pseudoelastic alloys demonstrate reversible deformation primarily through stress-induced phase transformations with strain recoveries typically around 6%. SMAs possess higher damping capacity and energy dissipation due to martensitic transformation, whereas pseudoelastic alloys excel in cyclic stability and fatigue resistance under repeated loading. Both materials offer unique mechanical performance, with SMAs favored for applications requiring shape recovery and pseudoelastic alloys preferred for high-cycle durability.

Thermal Response and Activation

Shape memory alloys exhibit a thermal response characterized by a phase transformation between martensite and austenite phases, activated by temperature changes typically ranging from -50degC to 150degC. Pseudoelastic alloys respond to mechanical stress by undergoing reversible deformation without permanent shape change, activated at temperatures above their austenite finish temperature, generally around room temperature. The thermal activation in shape memory alloys enables shape recovery upon heating, while pseudoelastic alloys rely on stress-induced phase transformation for their unique mechanical properties.

Common Materials and Alloy Systems

Shape memory alloys primarily include nickel-titanium (NiTi or Nitinol), copper-aluminum-nickel (Cu-Al-Ni), and copper-zinc-aluminum (Cu-Zn-Al) systems renowned for their thermally induced phase transformations. Pseudoelastic alloys, often based on NiTi compositions with tailored heat treatments, exhibit reversible stress-induced martensitic transformations at temperatures above their transformation range. Both alloy classes rely on closely related crystal structures, such as martensite and austenite phases, but differ in their ability to recover strain through temperature changes versus mechanical loading.

Applications: Medical, Aerospace, and Industrial

Shape memory alloys (SMAs) are widely utilized in medical devices such as stents, orthodontic wires, and surgical tools due to their ability to return to a predetermined shape after deformation. Pseudoelastic alloys, commonly applied in aerospace engineering, provide superior energy absorption and vibration damping for components exposed to cyclic loading and extreme environments. In industrial applications, SMAs are preferred for actuators and sensors that require precise shape recovery, while pseudoelastic alloys excel in flexible joints and connectors that endure repeated mechanical stress without permanent deformation.

Fabrication and Processing Techniques

Shape memory alloys (SMAs) and pseudoelastic alloys differ significantly in fabrication and processing techniques, with SMAs typically requiring controlled thermomechanical treatments such as solution annealing followed by aging to enhance phase transformation properties. Pseudoelastic alloys undergo precision processes like rapid quenching and cold working to stabilize the austenitic phase and optimize superelastic performance. Advanced methods such as electron beam melting and additive manufacturing are increasingly applied to tailor microstructures for both alloy types, improving mechanical properties and functional reliability.

Challenges and Future Perspectives in Alloy Development

Shape memory alloys (SMAs) face challenges such as limited fatigue life and temperature-dependent transformation behavior, restricting their broader application in industries requiring high durability and thermal stability. Pseudoelastic alloys, while offering improved flexibility and cyclic performance, still struggle with hysteresis and stress relaxation issues that affect long-term functionality. Future perspectives in alloy development emphasize enhancing fatigue resistance, reducing transformation hysteresis, and tailoring compositions at the nano-scale to optimize performance for biomedical, aerospace, and robotics applications.

Martensitic transformation

Shape memory alloys exhibit a reversible martensitic transformation enabling shape recovery upon heating, whereas pseudoelastic alloys display stress-induced martensitic transformation allowing large, recoverable strains at constant temperature.

Austenite phase

Shape memory alloys exhibit a stable austenite phase that enables reversible martensitic transformation for shape recovery, while pseudoelastic alloys maintain austenite at higher temperatures allowing for superelastic deformation without permanent shape change.

Thermal hysteresis

Shape memory alloys exhibit larger thermal hysteresis due to phase transformation involving martensitic reorientation, whereas pseudoelastic alloys show minimal thermal hysteresis as their deformation fully recovers upon unloading without temperature change.

Superelasticity

Shape memory alloys exhibit superelasticity through reversible phase transformations under mechanical stress, whereas pseudoelastic alloys maintain high elasticity with minimal permanent deformation by rapidly reverting to their original phase upon unloading.

Functional fatigue

Shape memory alloys exhibit reduced functional fatigue compared to pseudoelastic alloys due to their ability to recover strain through phase transformation, while pseudoelastic alloys often experience degradation in superelastic response after repeated cycling.

Two-way shape memory effect

Shape memory alloys exhibit a two-way shape memory effect enabling reversible shape changes upon heating and cooling, whereas pseudoelastic alloys primarily demonstrate superelasticity without a distinct two-way shape memory effect.

Detwinning

Detwinning in shape memory alloys involves the rearrangement of martensitic variants under stress that results in permanent deformation, whereas pseudoelastic alloys exhibit reversible detwinning allowing them to recover original shape immediately after unloading.

Stress-induced phase transition

Shape memory alloys undergo stress-induced phase transitions that enable thermal shape recovery, while pseudoelastic alloys exhibit reversible stress-induced phase transitions allowing immediate strain recovery without temperature change.

Transformation temperature window

Shape memory alloys exhibit a broader transformation temperature window than pseudoelastic alloys, enabling more versatile applications across varied thermal environments.

Hysteretic energy dissipation

Shape memory alloys exhibit superior hysteretic energy dissipation compared to pseudoelastic alloys due to their stress-induced martensitic phase transformation and reversible strain recovery mechanisms.

Shape memory alloys vs Pseudoelastic alloys Infographic

njnir.com

njnir.com