Grain refinement enhances mechanical properties by reducing grain size, leading to increased strength and toughness through the Hall-Petch effect. Alloying introduces elemental combinations that modify phase structures and influence corrosion resistance, hardness, and ductility. Combining grain refinement with strategic alloying often yields synergistic improvements in material performance for engineering applications.

Table of Comparison

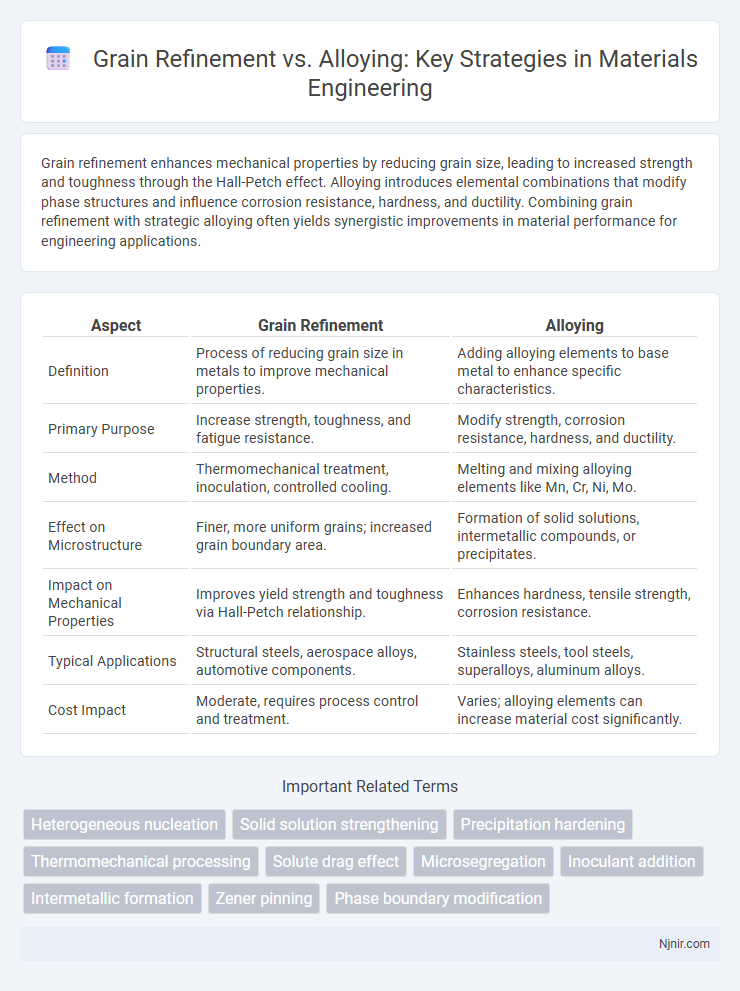

| Aspect | Grain Refinement | Alloying |

|---|---|---|

| Definition | Process of reducing grain size in metals to improve mechanical properties. | Adding alloying elements to base metal to enhance specific characteristics. |

| Primary Purpose | Increase strength, toughness, and fatigue resistance. | Modify strength, corrosion resistance, hardness, and ductility. |

| Method | Thermomechanical treatment, inoculation, controlled cooling. | Melting and mixing alloying elements like Mn, Cr, Ni, Mo. |

| Effect on Microstructure | Finer, more uniform grains; increased grain boundary area. | Formation of solid solutions, intermetallic compounds, or precipitates. |

| Impact on Mechanical Properties | Improves yield strength and toughness via Hall-Petch relationship. | Enhances hardness, tensile strength, corrosion resistance. |

| Typical Applications | Structural steels, aerospace alloys, automotive components. | Stainless steels, tool steels, superalloys, aluminum alloys. |

| Cost Impact | Moderate, requires process control and treatment. | Varies; alloying elements can increase material cost significantly. |

Introduction to Grain Refinement and Alloying

Grain refinement enhances mechanical properties by reducing grain size, which increases grain boundary area and inhibits dislocation motion. Alloying introduces specific elements into a base metal to alter its chemical composition, thereby improving strength, corrosion resistance, and thermal stability. Combining grain refinement with alloying optimizes material performance by balancing microstructural control and compositional modification.

Fundamental Principles of Grain Refinement

Grain refinement improves metal properties by reducing grain size through controlled nucleation and growth during solidification, enhancing strength and toughness without altering chemical composition. Alloying modifies mechanical and physical characteristics by introducing specific elements that change the metal's phase structure and hardness. Fundamental principles of grain refinement involve manipulating cooling rates and inoculants to create numerous fine grains that impede dislocation motion and improve overall material performance.

Mechanisms of Alloying in Materials Engineering

Alloying in materials engineering involves the deliberate introduction of additional elements into a base metal to alter its microstructure and enhance properties such as strength, hardness, and corrosion resistance. These elements dissolve either interstitially or substitutionally, leading to changes in lattice parameters, formation of secondary phases, and solid solution strengthening. Compared to grain refinement, alloying mechanisms provide a more diverse range of property modifications through chemical interactions rather than solely modifying grain size.

Grain Size Effect on Mechanical Properties

Grain refinement significantly improves mechanical properties by reducing grain size, which enhances yield strength and toughness according to the Hall-Petch relationship. Alloying elements influence grain size indirectly by affecting solidification rates and phase transformations, thereby tailoring strength, ductility, and hardness. Optimizing grain size through controlled refinement provides superior mechanical performance compared to relying solely on alloying additions.

Alloying Elements and Their Influence

Alloying elements such as chromium, nickel, and molybdenum play a critical role in enhancing mechanical properties by forming solid solutions and precipitates that improve strength and corrosion resistance. These elements alter the phase composition and microstructure, leading to refined grain sizes that boost toughness and fatigue life. The precise selection and concentration of alloying elements directly influence the grain boundary characteristics and overall material performance in various industrial applications.

Comparative Advantages: Grain Refinement vs Alloying

Grain refinement enhances mechanical properties by producing a finer microstructure, leading to increased strength, toughness, and resistance to fatigue and corrosion without significantly altering the chemical composition. Alloying introduces additional elements that change the material's overall properties, such as improving hardness, wear resistance, and thermal stability, but can sometimes reduce ductility. Grain refinement offers superior control over microstructural features for uniform performance, while alloying provides targeted enhancements by modifying the chemical makeup.

Limitations and Challenges of Each Approach

Grain refinement enhances mechanical properties by reducing grain size but faces limitations such as grain coarsening at high temperatures and increased processing costs. Alloying improves strength and corrosion resistance through solute atoms but may induce brittleness, segregation, or formation of undesirable phases. Both approaches encounter challenges in balancing property improvements with material stability and manufacturability.

Processing Techniques for Grain Refinement

Grain refinement processing techniques primarily include rapid solidification, severe plastic deformation, and thermomechanical treatments such as controlled rolling and recrystallization annealing. These methods enhance mechanical properties by producing ultrafine or refined grains that improve strength, toughness, and fatigue resistance without significantly altering alloy chemistry. Compared to alloying, which modifies material composition, grain refinement through processing optimizes microstructure and performance via controlled deformation and heat treatments.

Industrial Applications and Case Studies

Grain refinement enhances mechanical properties such as strength and toughness in metals, making it essential for aerospace and automotive components where reliability under stress is critical. Alloying introduces specific elements to modify composition, optimizing corrosion resistance, machinability, and thermal stability crucial for marine and chemical processing industries. Industrial case studies reveal that grain-refined aluminum alloys in aircraft structures outperform conventional alloys, while alloyed stainless steels in pipeline systems demonstrate superior durability and reduced maintenance costs.

Future Trends in Grain Refinement and Alloying

Emerging future trends in grain refinement focus on advanced techniques such as severe plastic deformation and additive manufacturing to achieve ultrafine grain structures, significantly enhancing mechanical properties and corrosion resistance. Innovations in alloying emphasize the development of high-entropy alloys and nanostructured composites to optimize performance under extreme conditions and improve sustainability through reduced critical element reliance. Integration of machine learning and computational materials science accelerates the design of grain refinement and alloying strategies, enabling tailored microstructures for next-generation applications in aerospace, automotive, and energy sectors.

Heterogeneous nucleation

Grain refinement enhances heterogeneous nucleation by increasing the number of nucleation sites through inoculants, whereas alloying modifies chemical composition to influence nucleation energy barriers and grain growth dynamics.

Solid solution strengthening

Grain refinement enhances solid solution strengthening by increasing grain boundary area to impede dislocation motion, while alloying introduces solute atoms that distort the lattice and further hinder dislocation movement for improved material strength.

Precipitation hardening

Grain refinement enhances precipitation hardening by increasing the number of nucleation sites for precipitates, while alloying introduces specific elements that form strengthening precipitates through controlled heat treatment.

Thermomechanical processing

Grain refinement during thermomechanical processing enhances mechanical strength and ductility by controlling recrystallization and phase transformations more effectively than traditional alloying methods.

Solute drag effect

Grain refinement improves mechanical properties by creating finer grains that impede dislocation movement, while alloying induces the solute drag effect where solute atoms slow grain boundary migration, enhancing stability and strength.

Microsegregation

Grain refinement reduces microsegregation by promoting uniform solute distribution during solidification, whereas alloying can increase microsegregation due to differences in element partitioning and solidification behavior.

Inoculant addition

Inoculant addition primarily enhances grain refinement by promoting nucleation and reducing grain size more effectively than traditional alloying elements, improving mechanical properties and casting quality.

Intermetallic formation

Grain refinement enhances mechanical properties by creating finer grain structures, while alloying promotes intermetallic formation that significantly influences hardness and corrosion resistance in metals.

Zener pinning

Zener pinning effectively controls grain refinement by stabilizing grain boundaries through finely dispersed second-phase particles, contrasting alloying which primarily alters the chemical composition to influence mechanical properties.

Phase boundary modification

Grain refinement enhances phase boundary modification by increasing grain boundary area and energy, which improves mechanical properties, whereas alloying alters phase boundaries through solute segregation and precipitation strengthening to stabilize microstructure.

Grain refinement vs Alloying Infographic

njnir.com

njnir.com