Metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) represent two pivotal classes of porous materials distinguished by their bonding types, with MOFs constructed via metal-ligand coordination bonds and COFs featuring strong covalent bonds between organic building blocks. MOFs typically exhibit higher surface areas and tunable pore sizes, making them ideal for gas storage and catalysis, while COFs offer superior thermal stability and crystallinity beneficial for separation and sensing applications. The choice between MOFs and COFs depends on the specific application requirements, balancing factors such as chemical stability, structural flexibility, and functionalization capabilities.

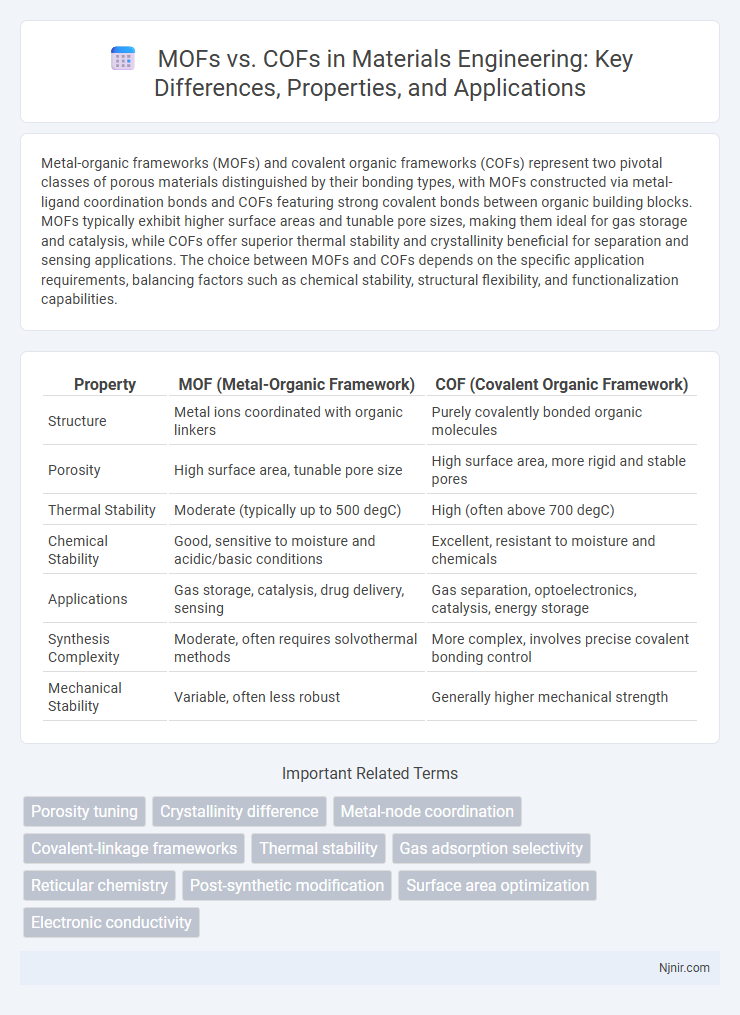

Table of Comparison

| Property | MOF (Metal-Organic Framework) | COF (Covalent Organic Framework) |

|---|---|---|

| Structure | Metal ions coordinated with organic linkers | Purely covalently bonded organic molecules |

| Porosity | High surface area, tunable pore size | High surface area, more rigid and stable pores |

| Thermal Stability | Moderate (typically up to 500 degC) | High (often above 700 degC) |

| Chemical Stability | Good, sensitive to moisture and acidic/basic conditions | Excellent, resistant to moisture and chemicals |

| Applications | Gas storage, catalysis, drug delivery, sensing | Gas separation, optoelectronics, catalysis, energy storage |

| Synthesis Complexity | Moderate, often requires solvothermal methods | More complex, involves precise covalent bonding control |

| Mechanical Stability | Variable, often less robust | Generally higher mechanical strength |

Introduction to MOFs and COFs

Metal-Organic Frameworks (MOFs) are crystalline materials composed of metal ions or clusters coordinated to organic ligands, forming porous structures with high surface area and tunable functionality. Covalent Organic Frameworks (COFs) are fully organic, crystalline polymers constructed from light elements (C, H, O, N, B) connected by strong covalent bonds, offering high thermal stability and precise pore design. Both MOFs and COFs are pivotal in applications such as gas storage, catalysis, and sensing due to their modularity and controllable porosity.

Structural Differences: MOF vs COF

Metal-Organic Frameworks (MOFs) feature a crystalline structure composed of metal ions or clusters coordinated to organic ligands, resulting in highly porous, often flexible frameworks. Covalent Organic Frameworks (COFs), in contrast, consist entirely of light elements linked by strong covalent bonds into rigid, two- or three-dimensional networks without metal centers. The coordination bonds in MOFs offer dynamic tunability, whereas the covalent bonds in COFs provide enhanced chemical stability and defined pore architectures.

Synthesis Methods and Techniques

MOFs (Metal-Organic Frameworks) are typically synthesized using solvothermal and hydrothermal methods involving metal ions and organic ligands under controlled temperature and pressure, promoting crystalline growth. COFs (Covalent Organic Frameworks) rely on reversible covalent bond formation techniques such as Schiff base condensation and boronate ester formation, employing solvothermal conditions or room temperature reactions to achieve crystalline porous structures. Both frameworks utilize template-free synthesis, but MOFs' metal-ligand coordination contrasts COFs' purely covalent bonding, influencing their stability and functional tunability.

Porosity and Surface Area Comparison

Metal-Organic Frameworks (MOFs) typically exhibit higher porosity and larger surface areas compared to Covalent Organic Frameworks (COFs) due to their metal-cluster nodes and versatile coordination geometries. MOFs can achieve surface areas exceeding 7000 m2/g, whereas COFs generally range between 1000-3000 m2/g, reflecting differences in structural tunability and pore size distribution. The enhanced porosity and surface area of MOFs make them advantageous for applications in gas storage, separation, and catalysis relative to COFs.

Thermal and Chemical Stability

Metal-Organic Frameworks (MOFs) exhibit superior thermal stability, often withstanding temperatures above 300degC due to strong metal-ligand coordination bonds, whereas Covalent Organic Frameworks (COFs) typically decompose at lower temperatures around 400degC but excel in chemical stability due to robust covalent bonding networks. MOFs can be susceptible to hydrolysis in humid or acidic environments, which limits their chemical stability, while COFs demonstrate enhanced resistance to solvents, acids, and bases, making them more chemically stable in harsh conditions. The choice between MOF and COF materials depends heavily on the specific application requirements for thermal endurance and chemical resilience.

Applications in Gas Storage and Separation

Metal-Organic Frameworks (MOFs) exhibit exceptional gas storage and separation capabilities due to their high surface area, tunable pore sizes, and strong adsorption sites, making them ideal for applications such as hydrogen storage, carbon dioxide capture, and methane purification. Covalent Organic Frameworks (COFs) offer similar advantages with lighter, more chemically stable structures and customizable porosity, enhancing selective gas separation and storage efficiency for industrial gas purification and environmental remediation. Both MOFs and COFs demonstrate significant potential in gas storage and separation technologies, with MOFs often preferred for higher adsorption capacity and COFs favored for structural stability and processability.

Catalytic Performance and Functionalization

Metal-Organic Frameworks (MOFs) exhibit superior catalytic performance due to their high surface area, tunable pore sizes, and diverse metal nodes which facilitate active site accessibility. Covalent Organic Frameworks (COFs) offer enhanced functionalization possibilities with stable covalent bonds, enabling precise incorporation of catalytic groups and organic functionalities for selective reactions. MOFs generally excel in catalytic activity for redox reactions, while COFs provide customizable frameworks for tailored catalysis in organic transformations.

Environmental and Energy Applications

Metal-Organic Frameworks (MOFs) exhibit superior porosity and structural tunability compared to Covalent Organic Frameworks (COFs), enhancing their capacity for gas storage, carbon capture, and catalytic energy conversion. MOFs' metal nodes facilitate efficient adsorption and activation of small molecules, while COFs' robust covalent bonds offer exceptional thermal and chemical stability, making them ideal for sustainable environmental remediation and energy storage. Both materials contribute significantly to advanced filtration, hydrogen storage, and CO2 sequestration technologies, with MOFs leading in dynamic adsorption and COFs excelling in durability under harsh operational conditions.

Limitations and Challenges

Metal-Organic Frameworks (MOFs) often face challenges related to chemical stability and scalability, as their metal nodes can be susceptible to moisture and harsh chemical environments, limiting practical industrial applications. Covalent Organic Frameworks (COFs), while offering superior chemical robustness due to strong covalent bonds, encounter difficulties in achieving high crystallinity and large-scale synthesis, which restricts their widespread use. Both MOFs and COFs require advancements in synthesis methods to overcome issues of reproducibility, structural defects, and processability for enhanced performance in gas storage, catalysis, and separation technologies.

Future Perspectives and Research Directions

Metal-Organic Frameworks (MOFs) and Covalent Organic Frameworks (COFs) both exhibit promising potential in catalysis, gas storage, and sensing applications, with research increasingly exploring their hybrid structures to enhance functionality and stability. Future perspectives emphasize the development of more robust, scalable, and environmentally friendly synthesis methods to achieve precise control over pore size, topology, and chemical functionality for targeted applications. Advancements in computational modeling and in situ characterization techniques are expected to accelerate the design of MOF-COF composites with tailored properties for energy storage, carbon capture, and drug delivery systems.

Porosity tuning

MOFs offer adjustable porosity through metal node selection and linker variation, whereas COFs achieve porosity tuning primarily via customizable organic building blocks and covalent bond topology.

Crystallinity difference

Metal-organic frameworks (MOFs) exhibit higher crystallinity due to their well-ordered metal-ligand coordination networks, whereas covalent organic frameworks (COFs) generally show lower crystallinity attributed to their covalent bond formation and limited long-range order.

Metal-node coordination

Metal-organic frameworks (MOFs) feature strong, well-defined metal-node coordination bonds that provide high structural stability, whereas covalent organic frameworks (COFs) rely primarily on covalent bonds with minimal or no metal-node coordination impacting their framework robustness.

Covalent-linkage frameworks

Covalent Organic Frameworks (COFs) feature robust covalent-linkage frameworks offering superior chemical stability and tunable porosity compared to Metal-Organic Frameworks (MOFs), which rely on metal-ligand coordination bonds.

Thermal stability

Metal-Organic Frameworks (MOFs) generally exhibit higher thermal stability than Covalent Organic Frameworks (COFs) due to their robust metal-ligand coordination bonds compared to the purely covalent bonds in COFs.

Gas adsorption selectivity

Metal-organic frameworks (MOFs) exhibit higher gas adsorption selectivity compared to covalent organic frameworks (COFs) due to their tunable pore sizes and diverse metal sites enabling stronger and more specific gas-molecule interactions.

Reticular chemistry

MOFs exhibit crystalline metal-ligand coordination networks with tunable porosity, while COFs feature covalently bonded organic frameworks enabling robust, designable reticular structures for applications in gas storage and catalysis.

Post-synthetic modification

Post-synthetic modification of metal-organic frameworks (MOFs) enables tailored functionalization through covalent or coordination chemistry, contrasting with covalent organic frameworks (COFs), which primarily undergo structural refinement via covalent bond transformations.

Surface area optimization

MOFs exhibit significantly higher surface area optimization than COFs due to their metal nodes and tunable pore structures enabling enhanced adsorption capacities.

Electronic conductivity

Metal-organic frameworks (MOFs) generally exhibit higher electronic conductivity compared to covalent organic frameworks (COFs) due to their metal nodes facilitating enhanced charge transport pathways.

MOF vs COF Infographic

njnir.com

njnir.com