Refractory metals like tungsten and molybdenum exhibit exceptional high-temperature strength and resistance to thermal creep, making them ideal for applications in extreme environments. Superalloys, primarily composed of nickel, cobalt, or iron, offer superior oxidation and corrosion resistance combined with excellent mechanical properties at elevated temperatures. The choice between refractory metals and superalloys depends on specific application requirements, such as temperature thresholds, mechanical stress, and environmental exposure.

Table of Comparison

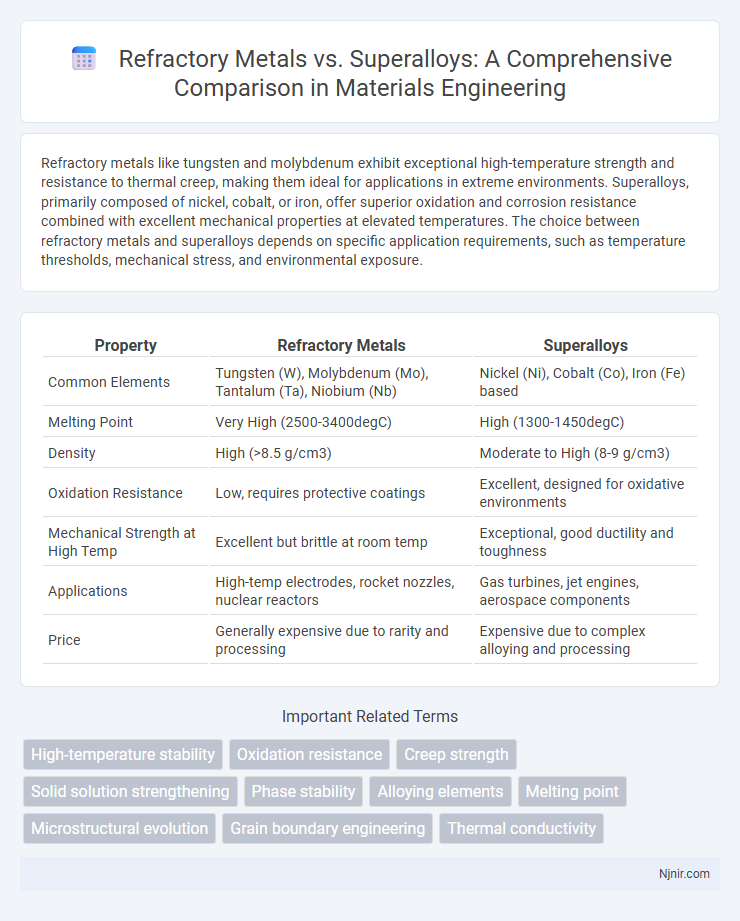

| Property | Refractory Metals | Superalloys |

|---|---|---|

| Common Elements | Tungsten (W), Molybdenum (Mo), Tantalum (Ta), Niobium (Nb) | Nickel (Ni), Cobalt (Co), Iron (Fe) based |

| Melting Point | Very High (2500-3400degC) | High (1300-1450degC) |

| Density | High (>8.5 g/cm3) | Moderate to High (8-9 g/cm3) |

| Oxidation Resistance | Low, requires protective coatings | Excellent, designed for oxidative environments |

| Mechanical Strength at High Temp | Excellent but brittle at room temp | Exceptional, good ductility and toughness |

| Applications | High-temp electrodes, rocket nozzles, nuclear reactors | Gas turbines, jet engines, aerospace components |

| Price | Generally expensive due to rarity and processing | Expensive due to complex alloying and processing |

Introduction to Refractory Metals and Superalloys

Refractory metals, including tungsten, molybdenum, tantalum, niobium, and rhenium, exhibit exceptional melting points and mechanical strength at high temperatures, making them essential for extreme environment applications. Superalloys, primarily nickel-, cobalt-, or iron-based alloys, provide outstanding resistance to thermal creep deformation, oxidation, and corrosion, commonly used in aerospace turbine engines and power plants. Both material classes are crucial for high-performance engineering due to their unique microstructural stability and mechanical properties under elevated temperature conditions.

Chemical Composition and Microstructure

Refractory metals such as tungsten, molybdenum, tantalum, niobium, and rhenium exhibit high melting points and exceptional thermal stability due to their high atomic weights and strong metallic bonds, characterized by body-centered cubic (BCC) microstructures. Superalloys, primarily based on nickel, cobalt, or iron, contain complex chemical compositions including elements like chromium, aluminum, titanium, and cobalt, promoting gamma-prime (g') precipitates in their face-centered cubic (FCC) microstructures, enhancing high-temperature strength and oxidation resistance. The microstructure of refractory metals is typically simpler with single-phase solid solutions, while superalloys possess multiphase microstructures engineered for creep resistance and mechanical durability at elevated temperatures.

Mechanical Properties Comparison

Refractory metals such as tungsten, molybdenum, tantalum, and niobium exhibit exceptional high melting points, superior hardness, and excellent creep resistance at elevated temperatures compared to superalloys. Superalloys, typically based on nickel or cobalt, provide outstanding tensile strength, oxidation resistance, and fatigue resistance while maintaining good ductility under high-temperature conditions. The mechanical properties of refractory metals favor applications demanding extreme temperature endurance and hardness, whereas superalloys excel in environments requiring a balance of strength, oxidation resistance, and toughness.

High-Temperature Performance

Refractory metals such as tungsten, molybdenum, and tantalum exhibit exceptional high-temperature performance with melting points exceeding 2,000degC, making them ideal for extreme thermal environments. Superalloys, predominantly nickel-based, maintain strength and corrosion resistance at temperatures up to 1,200degC, optimizing performance in aerospace and power generation applications. The superior high-temperature creep resistance and oxidation stability of superalloys contrast with the unrivaled melting points and thermal conductivity of refractory metals.

Corrosion and Oxidation Resistance

Refractory metals such as tungsten, molybdenum, and tantalum exhibit superior high-temperature strength but often suffer from limited oxidation resistance in atmospheric conditions, necessitating protective coatings or controlled environments. Superalloys, typically nickel- or cobalt-based, are engineered for exceptional corrosion and oxidation resistance due to their complex alloy compositions and the formation of stable oxide layers at elevated temperatures. The choice between refractory metals and superalloys depends heavily on the operational environment, with superalloys preferred for oxidative atmospheres and refractory metals used in inert or reducing conditions.

Manufacturing and Fabrication Techniques

Refractory metals such as tungsten, molybdenum, and tantalum require powder metallurgy and hot isostatic pressing due to their high melting points and brittleness at room temperature, while superalloys, primarily nickel-based, utilize casting, forging, and advanced directional solidification techniques to achieve complex geometries and superior mechanical properties. Electron beam melting (EBM) and additive manufacturing are increasingly applied for refractory metals to overcome fabrication challenges, whereas superalloys benefit from precise heat treatments and thermomechanical processing to optimize grain structure and phase distribution. The choice of manufacturing method directly affects the final performance characteristics, including creep resistance and oxidation behavior, which are critical for aerospace and high-temperature industrial applications.

Applications in Modern Industries

Refractory metals such as tungsten, molybdenum, and tantalum are crucial in high-temperature applications including aerospace engine components, nuclear reactors, and medical devices due to their exceptional melting points and thermal stability. Superalloys, typically based on nickel, cobalt, or iron, dominate industries requiring outstanding mechanical strength and oxidation resistance at elevated temperatures, like gas turbines, jet engines, and power plants. The selection between refractory metals and superalloys depends on specific operational demands such as temperature thresholds, corrosion resistance, and mechanical performance in harsh environments.

Cost and Availability Analysis

Refractory metals such as tungsten, molybdenum, and tantalum generally exhibit higher raw material costs and limited global availability due to their complex extraction and processing requirements. Superalloys, primarily composed of nickel, cobalt, or iron, benefit from more established supply chains and relatively lower material costs but can incur higher manufacturing expenses because of their intricate alloy compositions. Cost analysis must consider that refractory metals offer superior high-temperature performance but at a premium price, while superalloys provide a balanced cost-to-performance ratio with broader market accessibility.

Environmental and Sustainability Considerations

Refractory metals such as tungsten, molybdenum, and tantalum offer high-temperature stability and long service life, reducing resource consumption through enhanced durability in industrial applications. Superalloys, often based on nickel, cobalt, or iron, provide exceptional corrosion resistance and mechanical strength at elevated temperatures but may involve critical elements with supply chain vulnerabilities. Sustainable practices prioritize recycling and minimizing rare element usage in both materials to lower environmental impact and promote circular economy approaches in aerospace and energy sectors.

Future Trends and Research Directions

Refractory metals such as tungsten, molybdenum, and tantalum exhibit exceptional high-temperature strength and corrosion resistance, making them crucial for aerospace and nuclear applications, while superalloys like Inconel and Hastelloy dominate in high-stress turbine environments due to their superior creep resistance and oxidation stability. Future research emphasizes enhancing the high-temperature performance of refractory metals through alloying and nanostructuring techniques, alongside developing cost-effective, fuel-efficient superalloys with improved thermal barrier coatings. Emerging trends also include integrating additive manufacturing for complex component fabrication and advancing computational materials science to tailor microstructures for optimized mechanical properties at elevated temperatures.

High-temperature stability

Refractory metals exhibit superior high-temperature stability with melting points above 2000degC, outperforming superalloys that maintain strength up to approximately 1100degC.

Oxidation resistance

Refractory metals like tungsten and molybdenum exhibit lower oxidation resistance at high temperatures compared to superalloys, which contain protective oxide-forming elements such as chromium and aluminum that enhance their oxidation resistance in extreme environments.

Creep strength

Refractory metals such as tungsten and molybdenum exhibit superior creep strength at ultra-high temperatures compared to superalloys, making them ideal for extreme heat-resistant applications.

Solid solution strengthening

Refractory metals like tungsten and molybdenum exhibit superior solid solution strengthening compared to superalloys due to their higher melting points and stronger metallic bonding, enhancing high-temperature mechanical performance.

Phase stability

Refractory metals exhibit superior phase stability at extreme temperatures compared to superalloys, making them ideal for high-temperature structural applications.

Alloying elements

Refractory metals such as tungsten, molybdenum, and tantalum primarily rely on elements like rhenium and hafnium for alloying to enhance high-temperature strength, while superalloys incorporate elements like nickel, chromium, aluminum, and cobalt to improve oxidation resistance and mechanical performance at elevated temperatures.

Melting point

Refractory metals such as tungsten and molybdenum exhibit melting points above 3400degC, significantly higher than superalloys, which typically melt below 1500degC.

Microstructural evolution

Refractory metals exhibit slower microstructural evolution due to their high melting points and stable crystal structures, while superalloys undergo complex phase transformations and precipitation strengthening that enhance their high-temperature mechanical properties.

Grain boundary engineering

Grain boundary engineering enhances the high-temperature strength and creep resistance of refractory metals and superalloys by optimizing grain boundary character distribution and reducing intergranular failure susceptibility.

Thermal conductivity

Refractory metals exhibit significantly higher thermal conductivity compared to superalloys, making them more efficient for high-temperature heat dissipation applications.

Refractory Metals vs Superalloys Infographic

njnir.com

njnir.com