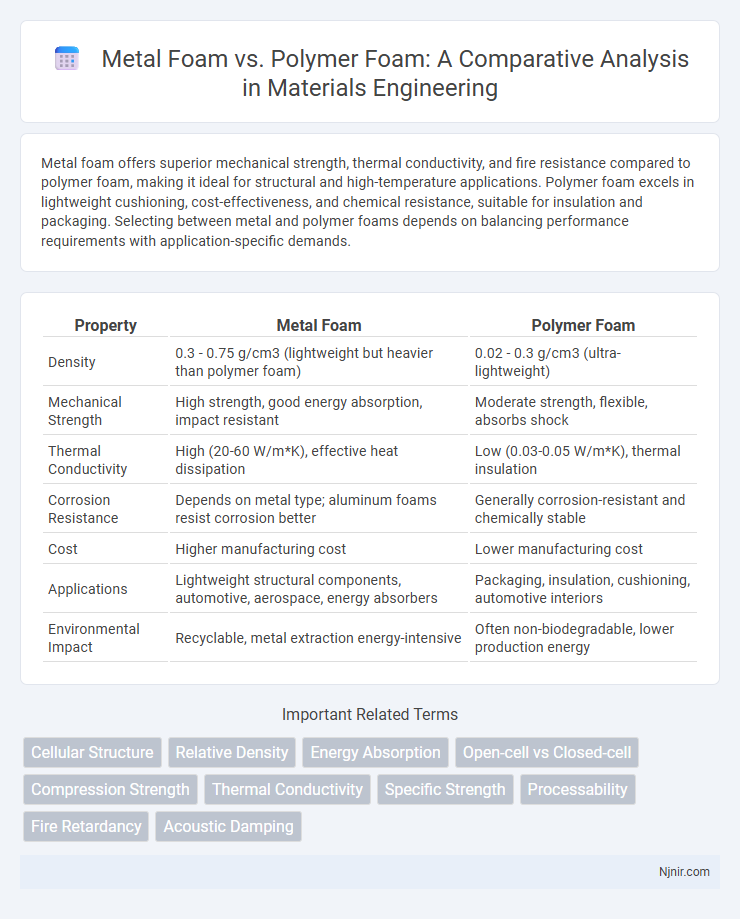

Metal foam offers superior mechanical strength, thermal conductivity, and fire resistance compared to polymer foam, making it ideal for structural and high-temperature applications. Polymer foam excels in lightweight cushioning, cost-effectiveness, and chemical resistance, suitable for insulation and packaging. Selecting between metal and polymer foams depends on balancing performance requirements with application-specific demands.

Table of Comparison

| Property | Metal Foam | Polymer Foam |

|---|---|---|

| Density | 0.3 - 0.75 g/cm3 (lightweight but heavier than polymer foam) | 0.02 - 0.3 g/cm3 (ultra-lightweight) |

| Mechanical Strength | High strength, good energy absorption, impact resistant | Moderate strength, flexible, absorbs shock |

| Thermal Conductivity | High (20-60 W/m*K), effective heat dissipation | Low (0.03-0.05 W/m*K), thermal insulation |

| Corrosion Resistance | Depends on metal type; aluminum foams resist corrosion better | Generally corrosion-resistant and chemically stable |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Applications | Lightweight structural components, automotive, aerospace, energy absorbers | Packaging, insulation, cushioning, automotive interiors |

| Environmental Impact | Recyclable, metal extraction energy-intensive | Often non-biodegradable, lower production energy |

Introduction to Metal Foam and Polymer Foam

Metal foam, characterized by its lightweight porous structure and high strength-to-weight ratio, is commonly used in aerospace, automotive, and construction industries for impact absorption and thermal management. Polymer foam, composed of lightweight polymeric materials with cellular structures, excels in insulation, cushioning, and noise reduction applications across packaging, furniture, and sports equipment sectors. Both metal and polymer foams offer distinct advantages based on their mechanical properties and functional performance in diverse industrial applications.

Manufacturing Processes of Metal vs Polymer Foams

Metal foam manufacturing typically involves powder metallurgy, metal infiltration, or gas injection methods, allowing precise control over pore size and distribution. Polymer foam production commonly uses processes such as chemical blowing agents, physical blowing agents, or extrusion foaming, offering versatility in density and cell structure. Metal foams generally require higher energy input and complex equipment compared to the more scalable and cost-effective polymer foam manufacturing techniques.

Material Composition and Structure Comparison

Metal foam consists primarily of metals such as aluminum, titanium, or steel with a porous, cellular structure that offers high strength-to-weight ratios and excellent thermal and electrical conductivity. Polymer foam is composed of organic polymers like polyurethane or polystyrene featuring a closed- or open-cell structure that provides superior insulation properties and flexibility but lower mechanical strength. The metallic matrix in metal foam creates a rigid, durable framework, whereas polymer foam's structure is lightweight and more adaptable for cushioning and shock absorption applications.

Mechanical Properties: Strength, Stiffness, and Durability

Metal foam exhibits superior strength and stiffness compared to polymer foam due to its metallic structure, making it ideal for load-bearing applications. Polymer foam offers lower stiffness but excels in impact absorption and flexibility, providing durability in cushioning and insulation uses. The durability of metal foam surpasses polymer foam under high-temperature or corrosive environments, while polymer foam maintains resilience under cyclic loading and moisture exposure.

Thermal and Acoustic Insulation Capabilities

Metal foam offers superior thermal conductivity compared to polymer foam, making it effective for heat dissipation in high-temperature environments, while polymer foam excels in thermal insulation due to its low thermal conductivity and closed-cell structure. In terms of acoustic insulation, polymer foam provides better sound absorption and noise reduction because of its porous composition and ability to trap air, whereas metal foam's rigid structure results in less effective sound dampening. The choice between metal foam and polymer foam depends on whether thermal management or acoustic insulation is the priority for the application.

Weight Considerations and Density Differences

Metal foam typically has a higher density than polymer foam, resulting in increased weight despite its porous structure. Polymer foam offers significantly lower weight due to its organic composition and lower material density, making it ideal for applications requiring lightweight materials. Weight considerations are critical in aerospace and automotive industries where polymer foam's favorable density-to-weight ratio enhances fuel efficiency and performance.

Corrosion Resistance and Environmental Stability

Metal foam exhibits superior corrosion resistance compared to polymer foam due to its metallic composition, which can be further enhanced by surface treatments like anodizing or coating. Polymer foam, however, is inherently resistant to many chemical environments and does not corrode, but may degrade under prolonged exposure to UV radiation or extreme temperatures. Environmental stability in metal foam depends on the specific alloy and protective layers, while polymer foam stability varies with polymer type, often requiring additives to improve resistance to environmental stressors.

Cost Analysis: Production and Lifecycle Costs

Metal foam typically involves higher initial production costs due to expensive raw materials and energy-intensive manufacturing processes, but offers superior durability and thermal resistance. Polymer foam production costs are generally lower because of affordable raw materials and simpler fabrication techniques, yet they may incur higher lifecycle costs from degradation and replacement frequency. Evaluating total cost of ownership highlights metal foam's long-term savings in maintenance and longevity compared to the short-term affordability but limited lifespan of polymer foam.

Applications in Industry: Automotive, Aerospace, and Construction

Metal foam offers superior strength-to-weight ratio and excellent energy absorption, making it ideal for automotive crash protection, aerospace structural components, and lightweight building materials in construction. Polymer foam excels in thermal and acoustic insulation, commonly used in automotive interiors, aerospace cabin insulation, and construction soundproofing panels. Both materials contribute to sustainability by enhancing fuel efficiency in vehicles and aircraft while providing durable, lightweight solutions in modern construction projects.

Future Trends and Innovations in Foam Materials

Emerging trends in foam materials emphasize the integration of metal foam's high strength-to-weight ratio with polymer foam's superior insulation properties, fostering hybrid composites for aerospace and automotive applications. Advances in nanotechnology enable the development of metal foams with enhanced thermal conductivity and polymer foams with improved biodegradability, addressing sustainability challenges. Innovations in additive manufacturing facilitate the precise control of foam microstructures, optimizing mechanical performance and expanding the potential for customized lightweight structures.

Cellular Structure

Metal foam exhibits a rigid, interconnected cellular structure with high strength and thermal conductivity, while polymer foam features a flexible, closed or open-cell structure optimized for lightweight insulation and cushioning.

Relative Density

Metal foam exhibits a higher relative density compared to polymer foam, typically ranging from 0.3 to 0.9 g/cm3 versus polymer foam's 0.01 to 0.1 g/cm3, influencing their respective mechanical strength and thermal conductivity.

Energy Absorption

Metal foam exhibits superior energy absorption capacity compared to polymer foam, making it ideal for impact protection and crashworthiness applications.

Open-cell vs Closed-cell

Metal foam offers superior strength and thermal conductivity in closed-cell structures, while polymer foam excels in open-cell forms with higher flexibility and sound absorption.

Compression Strength

Metal foam exhibits significantly higher compression strength than polymer foam, making it ideal for applications requiring superior load-bearing capacity and impact resistance.

Thermal Conductivity

Metal foam exhibits significantly higher thermal conductivity, typically ranging from 10 to 70 W/m*K, compared to polymer foam's low thermal conductivity of around 0.02 to 0.05 W/m*K, making metal foam superior for heat dissipation applications.

Specific Strength

Metal foam exhibits significantly higher specific strength than polymer foam due to its superior strength-to-weight ratio and structural rigidity.

Processability

Metal foam offers superior thermal conductivity and structural strength but requires complex casting or powder metallurgy processes, whereas polymer foam provides easier moldability and faster production through injection molding or extrusion with lower temperature constraints.

Fire Retardancy

Metal foam exhibits superior fire retardancy compared to polymer foam due to its inherent non-flammability and high thermal stability.

Acoustic Damping

Metal foam provides superior acoustic damping compared to polymer foam due to its porous structure and higher density, effectively reducing sound transmission and vibration in industrial and automotive applications.

Metal Foam vs Polymer Foam Infographic

njnir.com

njnir.com