Natural fiber composites offer enhanced sustainability by utilizing renewable resources, reducing environmental impact compared to synthetic fiber composites derived from petrochemicals. These composites exhibit lower density and improved biodegradability, making them suitable for lightweight applications with environmental considerations. However, synthetic fiber composites generally provide superior mechanical strength and durability, making them preferable for high-performance engineering applications.

Table of Comparison

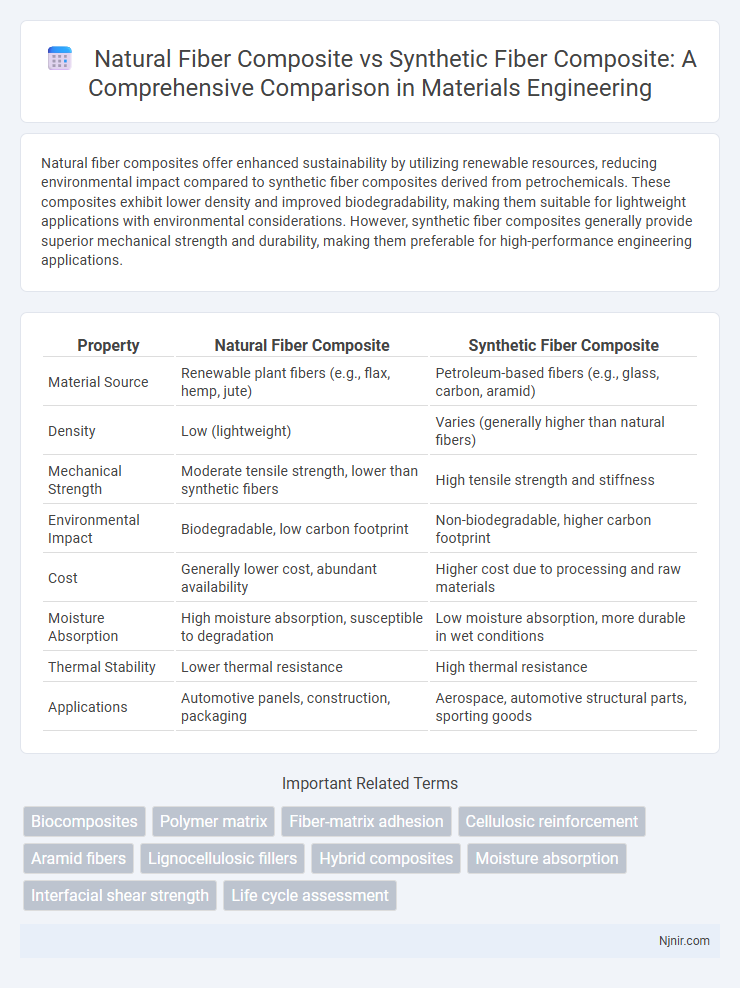

| Property | Natural Fiber Composite | Synthetic Fiber Composite |

|---|---|---|

| Material Source | Renewable plant fibers (e.g., flax, hemp, jute) | Petroleum-based fibers (e.g., glass, carbon, aramid) |

| Density | Low (lightweight) | Varies (generally higher than natural fibers) |

| Mechanical Strength | Moderate tensile strength, lower than synthetic fibers | High tensile strength and stiffness |

| Environmental Impact | Biodegradable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Cost | Generally lower cost, abundant availability | Higher cost due to processing and raw materials |

| Moisture Absorption | High moisture absorption, susceptible to degradation | Low moisture absorption, more durable in wet conditions |

| Thermal Stability | Lower thermal resistance | High thermal resistance |

| Applications | Automotive panels, construction, packaging | Aerospace, automotive structural parts, sporting goods |

Introduction to Fiber Composites in Materials Engineering

Fiber composites in materials engineering combine fibers with a matrix to enhance mechanical properties, offering lightweight and high-strength solutions. Natural fiber composites utilize renewable sources such as hemp, flax, or jute, providing advantages in biodegradability and lower environmental impact compared to synthetic fibers like glass or carbon. The choice between natural and synthetic fiber composites depends on specific application requirements, balancing factors such as strength-to-weight ratio, durability, and sustainability.

Classification: Natural vs Synthetic Fiber Composites

Natural fiber composites typically incorporate fibers such as jute, flax, hemp, or sisal combined with polymer matrices, offering advantages like biodegradability and lower density. Synthetic fiber composites commonly use fibers like glass, carbon, or aramid, known for superior mechanical properties and durability in demanding applications. Classification hinges on fiber origin--natural fibers derived from plants or animals versus synthetic fibers manufactured through chemical processes.

Material Properties and Performance Comparison

Natural fiber composites exhibit lower density and enhanced biodegradability compared to synthetic fiber composites, making them environmentally friendly alternatives. While synthetic fiber composites generally offer superior tensile strength, impact resistance, and durability due to fibers like carbon and glass, natural fibers such as hemp, flax, and jute provide adequate mechanical performance for low-load applications. Moisture absorption and thermal stability remain challenges for natural fiber composites, limiting their use in high-temperature or high-moisture environments relative to synthetic counterparts.

Environmental Impact and Sustainability

Natural fiber composites, derived from renewable resources such as flax, hemp, and jute, offer a significantly lower carbon footprint compared to synthetic fiber composites, which rely on petroleum-based materials like carbon or glass fibers. The biodegradability and reduced energy consumption during production contribute to the superior sustainability profile of natural fiber composites, making them ideal for eco-friendly applications. Conversely, synthetic fiber composites tend to generate more hazardous waste and pose challenges in recycling, leading to greater environmental impact over their lifecycle.

Manufacturing Processes and Techniques

Natural fiber composites are typically manufactured using techniques such as compression molding, resin transfer molding (RTM), and hand lay-up, which accommodate the variability and moisture sensitivity of fibers like flax, hemp, and jute. Synthetic fiber composites, such as those reinforced with carbon or glass fibers, often utilize more controlled processes including filament winding, pultrusion, and autoclave curing to achieve higher precision and consistent mechanical properties. The choice of manufacturing method directly impacts fiber-matrix adhesion, void content, and overall composite performance, with natural fibers requiring careful process optimization to mitigate issues like poor wetting and fiber degradation.

Cost Analysis and Economic Viability

Natural fiber composites typically offer lower material costs due to abundant renewable sources like hemp, flax, and jute, resulting in a cost advantage in large-scale production. Synthetic fiber composites, such as those reinforced with carbon or glass fibers, present higher upfront expenses but deliver superior mechanical properties, impacting their economic viability in high-performance applications. Lifecycle cost analysis often favors natural fiber composites for automotive and construction industries due to reduced environmental impact and lower processing energy requirements.

Mechanical Strength and Durability

Natural fiber composites exhibit moderate mechanical strength and durability, making them suitable for lightweight applications where biodegradability is prioritized. Synthetic fiber composites, such as those reinforced with carbon or glass fibers, offer superior tensile strength, impact resistance, and long-term durability under harsh environmental conditions. The choice between natural and synthetic fibers depends on specific performance requirements, with synthetic composites favored in high-stress and prolonged-use scenarios.

Applications in Industry Sectors

Natural fiber composites find extensive applications in automotive and construction industries due to their lightweight, biodegradability, and cost-effectiveness, particularly in interior panels, insulation, and packaging materials. Synthetic fiber composites dominate aerospace, defense, and high-performance sporting goods sectors where superior strength, durability, and thermal resistance are critical. Both fiber composites play a significant role in marine and infrastructure industries, with natural fibers favored for eco-friendly solutions and synthetic composites chosen for high-load-bearing applications.

Challenges and Limitations

Natural fiber composites face challenges such as lower moisture resistance, limited thermal stability, and inconsistent fiber quality, which can reduce durability and performance compared to synthetic fiber composites. Synthetic fiber composites, while offering superior strength and reliability, encounter limitations including higher environmental impact, cost, and difficulties in recycling. Both materials require advancements in processing techniques and treatments to overcome these challenges and expand their application potential.

Future Trends and Research Directions

Natural fiber composites are gaining traction due to their sustainability, biodegradability, and lower carbon footprint compared to synthetic fiber composites, driving research towards enhancing mechanical properties and moisture resistance. Innovations in hybrid composites and bio-based matrix materials are key future trends aimed at improving durability and expanding applications in automotive and construction industries. Advances in nanotechnology and surface treatments are also pivotal in optimizing fiber-matrix adhesion and overall composite performance for next-generation eco-friendly materials.

Biocomposites

Biocomposites made from natural fiber composites offer enhanced biodegradability, lower environmental impact, and comparable mechanical properties compared to synthetic fiber composites, making them ideal for sustainable material applications.

Polymer matrix

Natural fiber composites feature biodegradable polymer matrices with lower environmental impact, while synthetic fiber composites utilize petroleum-based polymer matrices offering superior mechanical strength and thermal resistance.

Fiber-matrix adhesion

Natural fiber composites exhibit weaker fiber-matrix adhesion than synthetic fiber composites due to their hydrophilic nature and surface incompatibility, impacting mechanical properties and durability.

Cellulosic reinforcement

Cellulosic reinforcement in natural fiber composites offers biodegradable, renewable, and lightweight advantages over synthetic fiber composites, enhancing mechanical properties while reducing environmental impact.

Aramid fibers

Aramid fiber composites offer superior impact resistance, higher thermal stability, and enhanced tensile strength compared to natural fiber composites, making them ideal for advanced aerospace and ballistic applications.

Lignocellulosic fillers

Natural fiber composites with lignocellulosic fillers offer enhanced biodegradability, lower density, and improved environmental sustainability compared to synthetic fiber composites, which typically provide higher mechanical strength and durability.

Hybrid composites

Hybrid composites combining natural and synthetic fibers offer enhanced mechanical properties, environmental sustainability, and improved durability compared to purely natural or synthetic fiber composites.

Moisture absorption

Natural fiber composites typically exhibit higher moisture absorption than synthetic fiber composites due to the hydrophilic nature of natural fibers, impacting their mechanical performance and durability.

Interfacial shear strength

Natural fiber composites typically exhibit lower interfacial shear strength compared to synthetic fiber composites due to weaker fiber-matrix adhesion and higher moisture absorption.

Life cycle assessment

Natural fiber composites exhibit significantly lower environmental impacts in life cycle assessments, including reduced carbon footprint and energy consumption, compared to synthetic fiber composites.

natural fiber composite vs synthetic fiber composite Infographic

njnir.com

njnir.com