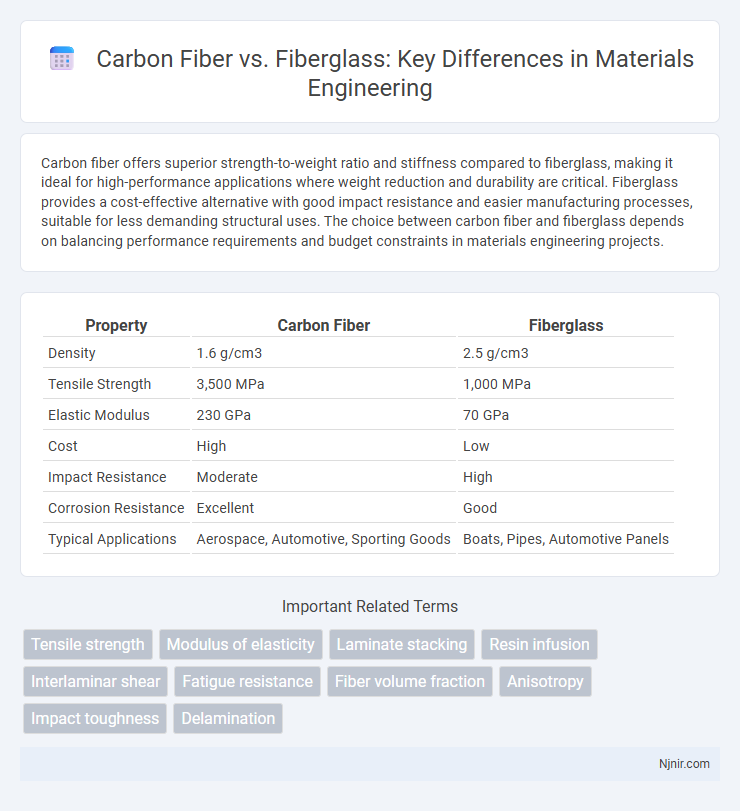

Carbon fiber offers superior strength-to-weight ratio and stiffness compared to fiberglass, making it ideal for high-performance applications where weight reduction and durability are critical. Fiberglass provides a cost-effective alternative with good impact resistance and easier manufacturing processes, suitable for less demanding structural uses. The choice between carbon fiber and fiberglass depends on balancing performance requirements and budget constraints in materials engineering projects.

Table of Comparison

| Property | Carbon Fiber | Fiberglass |

|---|---|---|

| Density | 1.6 g/cm3 | 2.5 g/cm3 |

| Tensile Strength | 3,500 MPa | 1,000 MPa |

| Elastic Modulus | 230 GPa | 70 GPa |

| Cost | High | Low |

| Impact Resistance | Moderate | High |

| Corrosion Resistance | Excellent | Good |

| Typical Applications | Aerospace, Automotive, Sporting Goods | Boats, Pipes, Automotive Panels |

Introduction to Carbon Fiber and Fiberglass

Carbon fiber is a lightweight, high-strength composite material composed of thin carbon strands woven into fabric and embedded in a resin matrix, widely used in aerospace, automotive, and sporting goods for its exceptional stiffness and durability. Fiberglass consists of fine glass fibers woven into mats or fabrics and combined with resin to create a strong, flexible composite commonly utilized in boat building, insulation, and automotive applications due to its corrosion resistance and cost-effectiveness. Both materials offer distinct performance characteristics, with carbon fiber excelling in strength-to-weight ratio and fiberglass providing affordability and impact resistance.

Composition and Material Structure

Carbon fiber consists of thin strands of carbon atoms bonded in a crystalline formation, providing high tensile strength and rigidity. Fiberglass is composed of fine glass fibers woven into a mat or cloth, offering flexibility and moderate strength. The lattice structure of carbon fiber results in superior strength-to-weight ratio compared to the amorphous, brittle nature of fiberglass materials.

Manufacturing Processes Compared

Carbon fiber manufacturing involves a complex process of polymerization, stabilization, carbonization, and surface treatment, resulting in high tensile strength and lightweight properties. Fiberglass production utilizes a simpler technique of melting glass and drawing it into fine fibers, followed by weaving or matting, which makes it cost-effective but less strong than carbon fiber. The precision and extensive energy consumption in carbon fiber fabrication contrast with fiberglass's scalable and lower-cost manufacturing process.

Mechanical Strength and Durability

Carbon fiber exhibits superior mechanical strength, with tensile strength typically ranging from 3,500 to 6,000 MPa, significantly outperforming fiberglass, which generally measures around 2,400 to 3,500 MPa. The stiffness of carbon fiber, indicated by its high modulus of elasticity (about 230-600 GPa), provides exceptional resistance to deformation under stress, whereas fiberglass has a lower modulus, averaging 70-85 GPa. Durability-wise, carbon fiber resists fatigue and environmental degradation better than fiberglass, maintaining structural integrity in harsh conditions like moisture exposure and ultraviolet radiation over extended periods.

Weight and Density Differences

Carbon fiber exhibits a significantly lower density, approximately 1.6 g/cm3, compared to fiberglass's density of around 2.5 g/cm3, making carbon fiber notably lighter. The reduced weight of carbon fiber contributes to enhanced performance in applications such as aerospace, automotive, and sports equipment where minimizing mass is critical. This weight advantage directly results from carbon fiber's superior strength-to-weight ratio, outperforming fiberglass in lightweight structural efficiency.

Cost Analysis and Economic Considerations

Carbon fiber generally commands a higher price point than fiberglass, with raw materials and manufacturing processes driving costs upward. Fiberglass offers a more budget-friendly alternative, making it preferable for applications requiring cost efficiency and moderate performance. Long-term economic considerations favor carbon fiber for high-performance industries due to its superior strength-to-weight ratio and durability, which reduce maintenance and replacement expenses.

Applications Across Industries

Carbon fiber offers superior strength-to-weight ratio and stiffness, making it ideal for aerospace, automotive, and high-performance sports equipment where lightweight durability is critical. Fiberglass is widely used in marine, construction, and wind energy industries due to its cost-effectiveness, corrosion resistance, and ease of fabrication. Both materials serve distinct roles, with carbon fiber favored for advanced engineering applications and fiberglass dominating in broader industrial manufacturing.

Environmental Impact and Sustainability

Carbon fiber production involves high energy consumption and emits more greenhouse gases compared to fiberglass, which is less energy-intensive but still relies on non-renewable petrochemicals. Fiberglass recycling is limited and often downcycled, while carbon fiber offers potential for reuse in high-performance applications, though recycling technologies are still developing. Sustainable alternatives are emerging in both materials, such as bio-based resins and recycled fibers, aimed at reducing environmental footprint and improving circularity.

Repairability and Maintenance

Carbon fiber offers superior strength-to-weight ratio but requires specialized repair techniques involving epoxy resins and precise curing conditions, making maintenance more complex and costly. Fiberglass, while less durable, is easier and more affordable to repair using common resins and tools, allowing for straightforward patching and refinishing. Regular inspection and prompt fixing of cracks in fiberglass extend its lifespan, whereas carbon fiber demands professional assessment to avoid compromising structural integrity.

Performance in Extreme Conditions

Carbon fiber exhibits superior performance in extreme conditions due to its high tensile strength and exceptional stiffness, maintaining structural integrity under intense stress and temperature variations. Fiberglass, while resistant to corrosion and heat, tends to flex and degrade faster when exposed to prolonged high stress or thermal cycling. The enhanced durability of carbon fiber makes it the preferred choice for aerospace and high-performance automotive applications requiring resilience in severe environments.

Tensile strength

Carbon fiber exhibits significantly higher tensile strength, often exceeding 5000 MPa, compared to fiberglass's typical tensile strength of around 3450 MPa, making carbon fiber the superior choice for applications demanding exceptional strength-to-weight ratios.

Modulus of elasticity

Carbon fiber has a modulus of elasticity typically around 230-600 GPa, significantly higher than fiberglass's 70-85 GPa, making carbon fiber much stiffer and more suitable for high-performance structural applications.

Laminate stacking

Carbon fiber offers superior strength-to-weight ratio and stiffness in laminate stacking compared to fiberglass, enabling thinner, lighter, and more durable composite structures.

Resin infusion

Carbon fiber offers superior strength-to-weight ratio and stiffness compared to fiberglass in resin infusion processes, resulting in lighter, more durable composite parts.

Interlaminar shear

Carbon fiber exhibits significantly higher interlaminar shear strength than fiberglass, enhancing its durability and resistance to delamination in composite structures.

Fatigue resistance

Carbon fiber exhibits superior fatigue resistance compared to fiberglass, maintaining structural integrity and performance under repetitive stress cycles in aerospace and automotive applications.

Fiber volume fraction

Carbon fiber composites typically achieve higher fiber volume fractions of 60-70% compared to fiberglass composites, which usually range from 30-50%, resulting in superior strength and stiffness for carbon fiber materials.

Anisotropy

Carbon fiber exhibits higher anisotropy with superior directional strength and stiffness compared to the more isotropic and flexible fiberglass material.

Impact toughness

Carbon fiber exhibits significantly higher impact toughness than fiberglass due to its superior tensile strength and energy absorption capabilities.

Delamination

Carbon fiber offers superior resistance to delamination compared to fiberglass due to its higher tensile strength and better matrix bonding properties.

carbon fiber vs fiberglass Infographic

njnir.com

njnir.com