Metal foams exhibit superior mechanical strength and thermal conductivity compared to aerogels, making them ideal for structural applications requiring lightweight yet durable materials. Aerogels, characterized by their extremely low density and high porosity, provide exceptional thermal insulation and acoustic damping, outperforming metal foams in energy efficiency. The choice between metal foams and aerogels ultimately depends on the balance between mechanical performance and insulation needs in materials engineering designs.

Table of Comparison

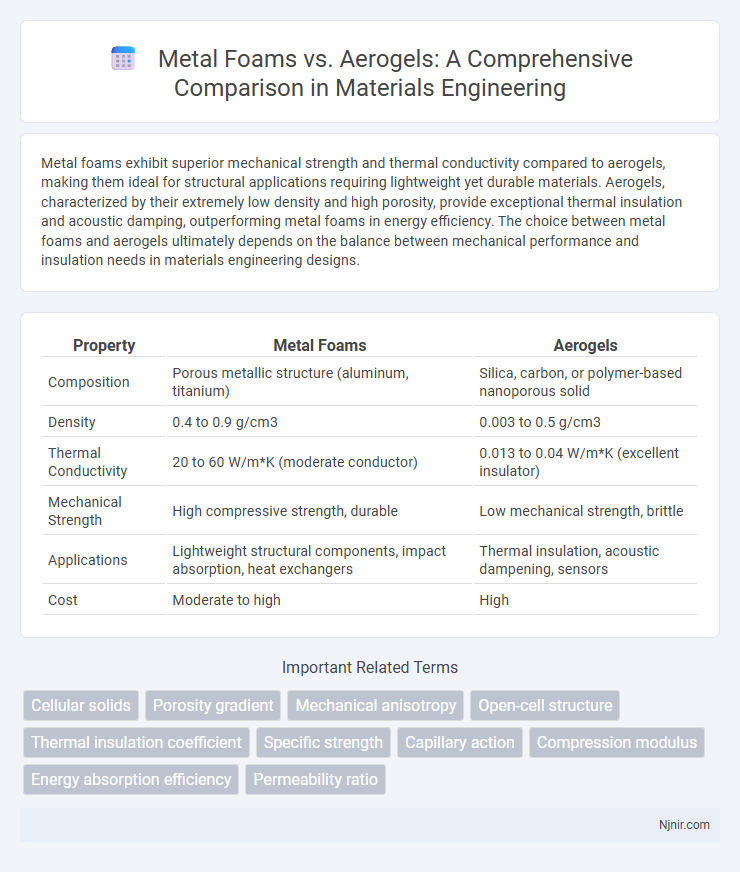

| Property | Metal Foams | Aerogels |

|---|---|---|

| Composition | Porous metallic structure (aluminum, titanium) | Silica, carbon, or polymer-based nanoporous solid |

| Density | 0.4 to 0.9 g/cm3 | 0.003 to 0.5 g/cm3 |

| Thermal Conductivity | 20 to 60 W/m*K (moderate conductor) | 0.013 to 0.04 W/m*K (excellent insulator) |

| Mechanical Strength | High compressive strength, durable | Low mechanical strength, brittle |

| Applications | Lightweight structural components, impact absorption, heat exchangers | Thermal insulation, acoustic dampening, sensors |

| Cost | Moderate to high | High |

Introduction to Metal Foams and Aerogels

Metal foams exhibit a unique cellular structure characterized by lightweight, high porosity, and excellent mechanical strength, making them ideal for applications in aerospace, automotive, and thermal management. Aerogels, composed of nanoscale silica or other materials, feature ultra-low density and extraordinary thermal insulation properties due to their high surface area and nanoporous structure. Both materials represent advanced lightweight solutions, with metal foams emphasizing structural robustness and aerogels offering superior insulation performance.

Synthesis and Fabrication Methods

Metal foams are typically synthesized through methods such as powder metallurgy, investment casting, or gas injection, which create a porous metallic structure with controlled pore size and distribution. Aerogels are fabricated via sol-gel processes followed by supercritical drying, preserving their ultra-lightweight and highly porous silica or polymer matrix. Both materials require precise control over fabrication parameters to optimize properties like density, thermal conductivity, and mechanical strength for applications in insulation, lightweight structures, and energy absorption.

Structural Characteristics and Morphology

Metal foams exhibit a porous structure composed of interconnected metallic ligaments, offering high mechanical strength and energy absorption due to their metallic matrix. Aerogels possess an ultra-lightweight, nanoporous morphology with a sparse network of silica or polymer chains, resulting in exceptional thermal insulation and low density. The structural characteristics of metal foams prioritize mechanical robustness, while aerogels emphasize minimal weight and thermal resistance through their distinct morphological properties.

Mechanical Properties Comparison

Metal foams exhibit high compressive strength and excellent energy absorption due to their cellular structure, making them ideal for impact protection applications. Aerogels, known for their ultra-low density and exceptional stiffness-to-weight ratio, generally have lower mechanical strength but superior thermal insulation properties. The mechanical performance of metal foams outperforms aerogels in load-bearing and deformation resistance, while aerogels excel in applications where lightweight and insulating capabilities are prioritized.

Thermal Insulation Capabilities

Metal foams exhibit moderate thermal insulation due to their porous structure combined with metal's high thermal conductivity, making them suitable for applications requiring strength and heat dissipation. Aerogels provide superior thermal insulation performance with extremely low thermal conductivity values, often as low as 0.013 W/m*K, attributed to their nanoporous silica-based framework. The choice between metal foams and aerogels depends on balancing insulation efficiency with mechanical properties and environmental resistance in specific applications.

Energy Absorption and Impact Resistance

Metal foams exhibit exceptional energy absorption and impact resistance due to their cellular structure, which effectively dissipates energy upon impact. Aerogels, while lightweight and excellent insulators, typically demonstrate lower impact resistance but can absorb energy through their highly porous network. Advances in material engineering are enhancing the toughness of aerogels, yet metal foams remain superior for applications requiring high mechanical energy absorption.

Electrical and Magnetic Properties

Metal foams exhibit excellent electrical conductivity due to their continuous metallic network, making them suitable for electromagnetic shielding and lightweight electrical components. Aerogels, typically composed of silica or carbon, offer superior dielectric properties with minimal electrical conductivity, ideal for insulation and sensor applications. Magnetic properties in metal foams depend on the base metal used, such as ferromagnetic iron foams, while aerogels generally show negligible magnetic response unless specifically doped with magnetic nanoparticles.

Environmental Sustainability and Recyclability

Metal foams offer high environmental sustainability due to their durability, lightweight properties, and excellent recyclability, as metals can be repeatedly melted and reformed without significant degradation. Aerogels, while providing exceptional thermal insulation and lightweight characteristics, face challenges in recyclability because their silica-based or polymer structures often require energy-intensive processing or disposal methods. The superior recyclability of metal foams contributes to a circular economy by minimizing waste and conserving raw materials, whereas aerogels demand innovative approaches to improve their end-of-life sustainability.

Industrial Applications and Case Studies

Metal foams exhibit superior impact absorption and thermal management properties, making them ideal for automotive crash structures and heat exchangers, while aerogels offer exceptional thermal insulation used extensively in aerospace and industrial pipeline coatings. Case studies reveal metal foams reducing vehicle weight by up to 30% without compromising safety, whereas aerogels enhance energy efficiency by cutting heat loss in industrial furnaces by over 50%. Both materials demonstrate unique advantages in industrial applications requiring lightweight durability and extreme thermal performance.

Future Trends and Research Directions

Future trends in metal foams emphasize enhanced mechanical strength and multifunctional applications, driven by research in additive manufacturing and nanotechnology to optimize porosity and thermal conductivity. Aerogels research is advancing towards improved scalability, environmental sustainability, and hybrid composites to boost insulation performance and structural integrity. Both materials show evolving integration in aerospace, energy storage, and biomedical fields, with ongoing studies targeting lightweight, high-strength solutions and enhanced thermal management.

Cellular solids

Metal foams and aerogels represent two distinct types of cellular solids, with metal foams characterized by their porous, metallic structure offering high strength-to-weight ratios and excellent energy absorption, while aerogels feature nanostructured, ultra-lightweight, and highly porous silica or organic networks providing superior thermal insulation and low density.

Porosity gradient

Metal foams exhibit a tunable porosity gradient that enhances mechanical strength and thermal conductivity, whereas aerogels primarily offer uniform high porosity with superior insulation but limited structural gradient control.

Mechanical anisotropy

Metal foams exhibit pronounced mechanical anisotropy due to their cellular structure, whereas aerogels demonstrate more isotropic mechanical properties because of their homogeneous nanoporous network.

Open-cell structure

Open-cell metal foams exhibit superior mechanical strength and thermal conductivity compared to aerogels, making them ideal for applications requiring lightweight materials with effective heat dissipation.

Thermal insulation coefficient

Metal foams generally have higher thermal insulation coefficients ranging from 0.05 to 0.30 W/m*K compared to aerogels, which exhibit exceptional thermal insulation with coefficients as low as 0.013 W/m*K.

Specific strength

Metal foams offer higher specific strength compared to aerogels, making them more suitable for lightweight structural applications requiring durability.

Capillary action

Metal foams exhibit stronger capillary action due to their interconnected porous structure and metallic surface energy compared to the ultra-light, hydrophobic networks in aerogels, making them more efficient for fluid transport applications.

Compression modulus

Metal foams exhibit a higher compression modulus ranging from 1 to 100 MPa compared to aerogels, which typically have a compression modulus below 1 MPa, making metal foams more suitable for load-bearing applications.

Energy absorption efficiency

Metal foams exhibit superior energy absorption efficiency compared to aerogels due to their cellular structure that provides enhanced impact resistance and mechanical strength.

Permeability ratio

Metal foams exhibit significantly higher permeability ratios than aerogels, enabling superior fluid flow and gas exchange in filtration and insulation applications.

Metal foams vs Aerogels Infographic

njnir.com

njnir.com