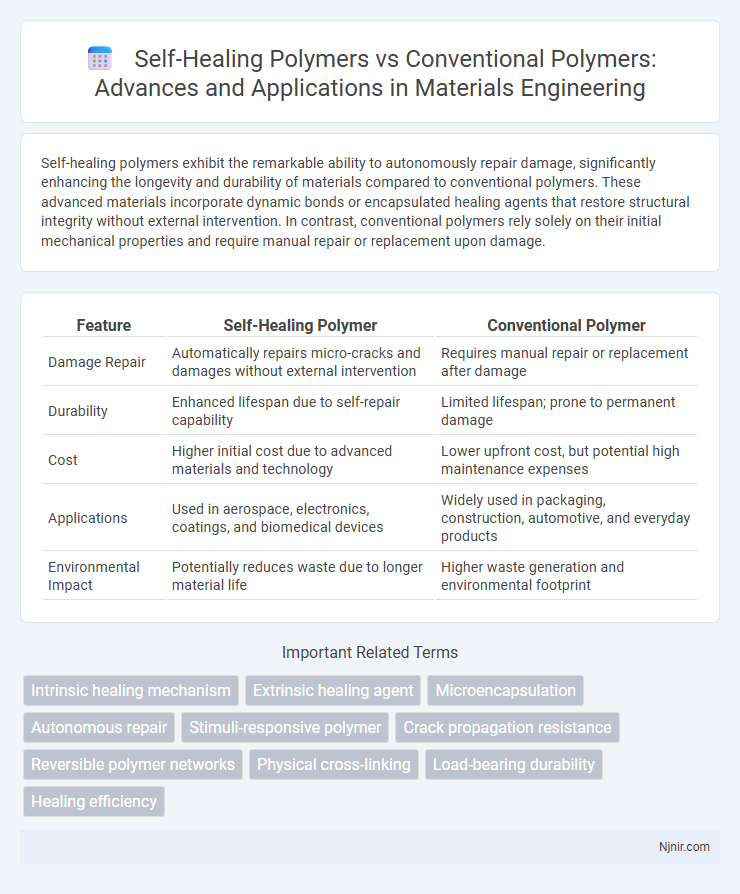

Self-healing polymers exhibit the remarkable ability to autonomously repair damage, significantly enhancing the longevity and durability of materials compared to conventional polymers. These advanced materials incorporate dynamic bonds or encapsulated healing agents that restore structural integrity without external intervention. In contrast, conventional polymers rely solely on their initial mechanical properties and require manual repair or replacement upon damage.

Table of Comparison

| Feature | Self-Healing Polymer | Conventional Polymer |

|---|---|---|

| Damage Repair | Automatically repairs micro-cracks and damages without external intervention | Requires manual repair or replacement after damage |

| Durability | Enhanced lifespan due to self-repair capability | Limited lifespan; prone to permanent damage |

| Cost | Higher initial cost due to advanced materials and technology | Lower upfront cost, but potential high maintenance expenses |

| Applications | Used in aerospace, electronics, coatings, and biomedical devices | Widely used in packaging, construction, automotive, and everyday products |

| Environmental Impact | Potentially reduces waste due to longer material life | Higher waste generation and environmental footprint |

Introduction to Polymers: Self-Healing vs Conventional

Self-healing polymers are advanced materials designed to autonomously repair damages, significantly enhancing durability and lifespan compared to conventional polymers, which lack intrinsic repair mechanisms. These innovative polymers employ microcapsules, reversible covalent bonds, or dynamic supramolecular interactions to restore structural integrity after mechanical stress or environmental wear. In contrast, conventional polymers typically require external intervention for maintenance, resulting in increased material degradation and higher lifecycle costs.

Fundamental Principles of Conventional Polymers

Conventional polymers consist of long molecular chains linked by covalent bonds, providing stability and mechanical strength through fixed cross-linking. These polymers lack intrinsic mechanisms to repair damage, which results in irreversible fracture or wear upon mechanical stress. Their structure relies on permanent chemical bonds that do not reform after breakage, limiting their lifespan compared to self-healing polymers designed with dynamic bonds or reversible interactions.

Mechanisms Underpinning Self-Healing Polymers

Self-healing polymers utilize dynamic covalent bonds or supramolecular interactions to autonomously repair damage, contrasting with conventional polymers which rely on passive structural integrity without repair capabilities. These mechanisms enable microcracks or fractures in self-healing polymers to reform chemical bonds or realign molecular chains, restoring mechanical properties and extending material lifespan. Incorporating reversible bond exchange, microencapsulated healing agents, or thermo-responsive segments distinguishes self-healing polymers from traditional polymers that lack such adaptive functionalities.

Comparative Mechanical Properties

Self-healing polymers exhibit enhanced mechanical properties over conventional polymers by autonomously repairing damage, which extends their durability and reduces failure rates. Unlike conventional polymers that suffer irreversible mechanical degradation after cracking or scratching, self-healing polymers regain tensile strength and elasticity through intrinsic or extrinsic healing mechanisms. This dynamic ability significantly improves impact resistance, fatigue life, and overall mechanical robustness in applications such as aerospace, automotive, and wearable electronics.

Durability and Lifecycle Analysis

Self-healing polymers significantly enhance durability by autonomously repairing micro-cracks, extending service life beyond conventional polymers that deteriorate irreversibly under stress. Lifecycle analysis reveals that self-healing polymers reduce maintenance costs and environmental impact due to fewer replacements, promoting sustainability. Conventional polymers exhibit shorter lifespans and higher waste generation, making self-healing variants critical for long-term performance optimization.

Environmental Impact and Sustainability

Self-healing polymers significantly reduce environmental impact by extending the lifespan of materials and decreasing the need for frequent replacements, which lowers waste generation compared to conventional polymers. These innovative materials often incorporate recyclable or bio-based components, enhancing sustainability by minimizing reliance on non-renewable resources. Their ability to autonomously repair damages reduces plastic pollution and conserves raw materials, positioning them as a greener alternative to traditional polymers in various applications.

Cost and Scalability Considerations

Self-healing polymers often incur higher initial production costs compared to conventional polymers due to complex formulations and specialized materials. Conventional polymers benefit from established, large-scale manufacturing processes that reduce per-unit expenses and enable mass market availability. Scalability of self-healing polymers remains a challenge, with ongoing research focused on optimizing synthesis methods to achieve cost-effective large-scale production suitable for industrial applications.

Real-World Applications: Case Studies

Self-healing polymers have demonstrated significant advantages in aerospace components where microcracks can autonomously repair, extending the lifespan of critical parts and reducing maintenance costs compared to conventional polymers. In electronics, self-healing materials enable flexible circuits to restore conductivity after damage, enhancing device durability and performance, unlike traditional polymers prone to permanent failure. Automotive industries benefit from self-healing coatings that minimize scratches and corrosion, improving vehicle aesthetics and safety more effectively than standard polymer finishes.

Future Trends in Polymer Technology

Self-healing polymers represent a transformative advancement over conventional polymers by enabling automatic repair of damages, thereby significantly extending material lifespan and reducing maintenance costs. Future trends in polymer technology emphasize integrating nanotechnology and stimuli-responsive mechanisms to enhance self-healing efficiency and multifunctionality. Research is increasingly focused on sustainable self-healing polymers with biodegradability and recyclability to meet environmental and industrial demands.

Challenges and Opportunities in Adoption

Self-healing polymers face challenges in scalability and cost-effectiveness compared to conventional polymers, limiting widespread industrial adoption despite their superior durability and reduced maintenance requirements. Opportunities lie in their potential to extend product lifespans and reduce environmental impact through decreased waste, presenting a strong case for investment in research and development. Advancements in material synthesis and processing technologies could bridge performance gaps, enabling broader application across automotive, aerospace, and electronics industries.

Intrinsic healing mechanism

Intrinsic self-healing polymers autonomously restore their mechanical properties through reversible covalent bonds or dynamic supramolecular interactions, unlike conventional polymers that lack such autonomous repair mechanisms.

Extrinsic healing agent

Extrinsic self-healing polymers contain encapsulated healing agents that release upon damage to repair the material, unlike conventional polymers which lack such embedded repair mechanisms.

Microencapsulation

Microencapsulation enhances the self-healing capacity of polymers by embedding microcapsules containing healing agents that rupture upon damage, whereas conventional polymers lack this autonomous repair mechanism.

Autonomous repair

Self-healing polymers autonomously repair damage at the molecular level without external intervention, unlike conventional polymers that require manual maintenance or replacement.

Stimuli-responsive polymer

Stimuli-responsive self-healing polymers autonomously repair damage upon specific environmental triggers, offering enhanced durability and longevity compared to conventional polymers lacking such adaptive properties.

Crack propagation resistance

Self-healing polymers exhibit significantly enhanced crack propagation resistance compared to conventional polymers by autonomously repairing microcracks and preventing failure.

Reversible polymer networks

Reversible polymer networks in self-healing polymers enable dynamic bond reformation, offering superior damage recovery and extended material lifespan compared to conventional polymers with permanent crosslinks.

Physical cross-linking

Self-healing polymers utilize reversible physical cross-linking mechanisms such as hydrogen bonds and metal-ligand interactions to restore structural integrity, unlike conventional polymers that rely on permanent covalent cross-links for mechanical stability.

Load-bearing durability

Self-healing polymers demonstrate superior load-bearing durability compared to conventional polymers by autonomously repairing microcracks and extending structural lifespan under repetitive stress.

Healing efficiency

Self-healing polymers exhibit healing efficiencies exceeding 90%, significantly outperforming conventional polymers that typically show minimal or no intrinsic self-repair capability.

self-healing polymer vs conventional polymer Infographic

njnir.com

njnir.com