Conductive polymers exhibit electrical conductivity due to their conjugated p-electron systems, making them suitable for applications in flexible electronics and sensors. In contrast, insulating polymers lack free charge carriers, providing excellent electrical insulation critical for protective coatings and dielectric layers. The selection between conductive and insulating polymers depends on the required electrical properties and specific functional demands in materials engineering.

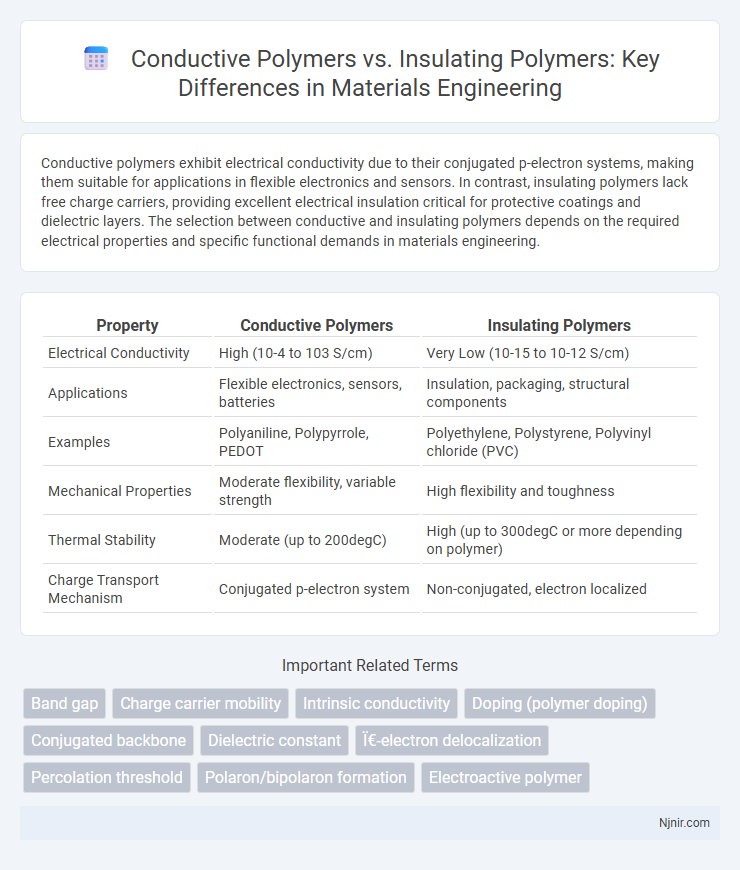

Table of Comparison

| Property | Conductive Polymers | Insulating Polymers |

|---|---|---|

| Electrical Conductivity | High (10-4 to 103 S/cm) | Very Low (10-15 to 10-12 S/cm) |

| Applications | Flexible electronics, sensors, batteries | Insulation, packaging, structural components |

| Examples | Polyaniline, Polypyrrole, PEDOT | Polyethylene, Polystyrene, Polyvinyl chloride (PVC) |

| Mechanical Properties | Moderate flexibility, variable strength | High flexibility and toughness |

| Thermal Stability | Moderate (up to 200degC) | High (up to 300degC or more depending on polymer) |

| Charge Transport Mechanism | Conjugated p-electron system | Non-conjugated, electron localized |

Introduction to Polymers: Conductive vs Insulating

Conductive polymers exhibit electrical conductivity due to their conjugated double bond structures, enabling electron mobility along the polymer backbone. In contrast, insulating polymers lack these conjugated systems, resulting in high electrical resistance and minimal charge transport. This fundamental difference defines their applications, with conductive polymers used in electronics and sensors, while insulating polymers serve as dielectric materials and protective coatings.

Chemical Structure Differences

Conductive polymers contain conjugated double bonds along their backbone, allowing delocalization of p-electrons, which facilitate electrical conductivity. Insulating polymers typically have saturated hydrocarbon chains without conjugation, preventing electron mobility and resulting in electrical insulation. The presence of alternating single and double bonds in conductive polymers creates a unique electronic structure distinct from the localized sigma bonds in insulating polymers.

Electrical Properties Comparison

Conductive polymers exhibit electrical conductivity due to delocalized p-electrons allowing charge transport, typically ranging from 10^-5 to 10^3 S/cm, whereas insulating polymers have negligible conductivity around 10^-14 to 10^-20 S/cm attributed to their saturated molecular structure. Conductive polymers like polyaniline, polypyrrole, and PEDOT can be doped to enhance conductivity, making them suitable for applications in flexible electronics and sensors. Insulating polymers such as polyethylene, polystyrene, and PVC provide excellent electrical insulation, mechanical stability, and chemical resistance, critical for protective coatings and electronic encapsulation.

Synthesis and Processing Techniques

Conductive polymers such as polyaniline and polypyrrole are synthesized primarily through electrochemical polymerization and chemical oxidative methods, enabling precise control over molecular weight and doping levels for enhanced electrical conductivity. In contrast, insulating polymers like polyethylene and polystyrene are produced via free radical polymerization or coordination polymerization, emphasizing bulk polymerization techniques for high thermal stability and mechanical strength. Processing conductive polymers often involves solution casting, spin coating, or vapor phase polymerization to achieve uniform thin films, whereas insulating polymers are typically processed through extrusion, injection molding, or blow molding for versatile structural applications.

Mechanical and Thermal Characteristics

Conductive polymers, such as polyaniline and polypyrrole, exhibit moderate mechanical flexibility but generally lower tensile strength compared to insulating polymers like polyethylene and polystyrene, which are known for their superior mechanical robustness. Thermal stability in conductive polymers tends to be lower, with decomposition temperatures typically around 200-300degC, whereas insulating polymers can withstand higher temperatures, often exceeding 300degC depending on their chemical structure. The intrinsic electrical conductivity of conductive polymers arises from their conjugated backbone, which also influences their thermal and mechanical properties, making them suitable for flexible electronics but less ideal for high-strength or high-temperature applications.

Applications of Conductive Polymers

Conductive polymers are widely used in flexible electronics, organic solar cells, and sensors due to their ability to conduct electricity while maintaining mechanical flexibility. Unlike insulating polymers, which serve primarily as dielectrics or protective coatings, conductive polymers are integral in developing lightweight, wearable devices and energy storage systems. Their applications also extend to antistatic coatings, electromagnetic interference shielding, and biomedical devices such as neural interfaces.

Uses of Insulating Polymers

Insulating polymers such as polyethylene, polystyrene, and PVC are widely used in electrical insulation due to their excellent dielectric properties and high resistance to electrical conductivity. These polymers are essential in applications like wire coatings, cable insulations, and electronic device housings, ensuring safety and durability in electrical systems. Their ability to prevent electrical currents from passing through makes them critical in protecting components and users from electrical hazards.

Challenges in Polymer Engineering

Conductive polymers face challenges in achieving long-term stability and consistent electrical conductivity under mechanical stress, which limits their application in flexible electronics. Insulating polymers encounter difficulties in enhancing thermal resistance and dielectric properties without compromising mechanical flexibility. Advances in polymer engineering focus on molecular design and filler integration to balance electrical performance with durability and processability.

Environmental Impact and Sustainability

Conductive polymers, such as polyaniline and polypyrrole, offer potential for sustainable electronic applications due to their lightweight nature and processability with fewer toxic metals compared to conventional conductors. Insulating polymers like polyethylene and polypropylene are widely used in packaging and construction but pose environmental concerns due to their persistence and low biodegradability, contributing significantly to plastic pollution. Advances in conductive polymer recycling and the development of biodegradable insulating polymers aim to reduce ecological footprints and enhance sustainability in polymer use.

Future Trends in Polymer Research

Future trends in polymer research emphasize the development of conductive polymers with enhanced electrical conductivity, flexibility, and environmental stability for applications in wearable electronics and energy storage devices. Innovations in molecular design and doping techniques are enabling insulating polymers to gain semiconducting properties, expanding their use in flexible electronics and sensors. Advances in nanocomposite formulations combining conductive and insulating polymers aim to create multifunctional materials with tailored electrical, mechanical, and thermal properties for next-generation smart devices.

Band gap

Conductive polymers exhibit a narrow band gap typically below 3 eV enabling electron mobility, whereas insulating polymers possess a wide band gap greater than 5 eV that restricts electrical conductivity.

Charge carrier mobility

Conductive polymers exhibit significantly higher charge carrier mobility, typically ranging from 10^-2 to 10 cm2/V*s, compared to insulating polymers whose mobility is often below 10^-10 cm2/V*s, enabling efficient electrical conductivity in organic electronic applications.

Intrinsic conductivity

Conductive polymers exhibit intrinsic conductivity due to their conjugated molecular structure enabling electron delocalization, whereas insulating polymers lack this conjugation and thus have negligible intrinsic conductivity.

Doping (polymer doping)

Doping enhances conductive polymers by introducing charge carriers that increase electrical conductivity, whereas insulating polymers remain non-conductive due to their lack of effective dopant interaction.

Conjugated backbone

Conductive polymers feature a conjugated backbone of alternating single and double bonds enabling electron delocalization and electrical conductivity, whereas insulating polymers lack this conjugated structure, resulting in poor electrical conductivity.

Dielectric constant

Conductive polymers typically exhibit lower dielectric constants than insulating polymers due to their delocalized p-electron systems, which reduce polarizability and energy storage capability in dielectric applications.

π-electron delocalization

Conductive polymers exhibit extensive p-electron delocalization along their conjugated backbone, enabling electrical conductivity, whereas insulating polymers lack such delocalization, resulting in poor charge transport properties.

Percolation threshold

Conductive polymers exhibit significantly lower percolation thresholds than insulating polymers, enabling efficient electrical conductivity at minimal filler concentrations.

Polaron/bipolaron formation

Conductive polymers exhibit polaron and bipolaron formation enabling charge transport, whereas insulating polymers lack these charged quasiparticles and remain electrically inactive.

Electroactive polymer

Electroactive polymers exhibit electrical conductivity and mechanical flexibility, contrasting with insulating polymers that lack charge transport capabilities, making conductive polymers ideal for applications in sensors, actuators, and flexible electronics.

Conductive polymers vs Insulating polymers Infographic

njnir.com

njnir.com