Shape Memory Alloys (SMAs) exhibit the ability to return to their original shape after deformation when exposed to a specific temperature, driven by a reversible martensitic phase transformation. Superelastic Alloys, a subset of SMAs, demonstrate exceptional elastic strain recovery at constant temperature due to stress-induced phase transformations, enabling significant deformation without permanent shape change. Both materials find critical applications in aerospace, biomedical devices, and robotics due to their unique mechanical properties and adaptive responses to thermal or mechanical stimuli.

Table of Comparison

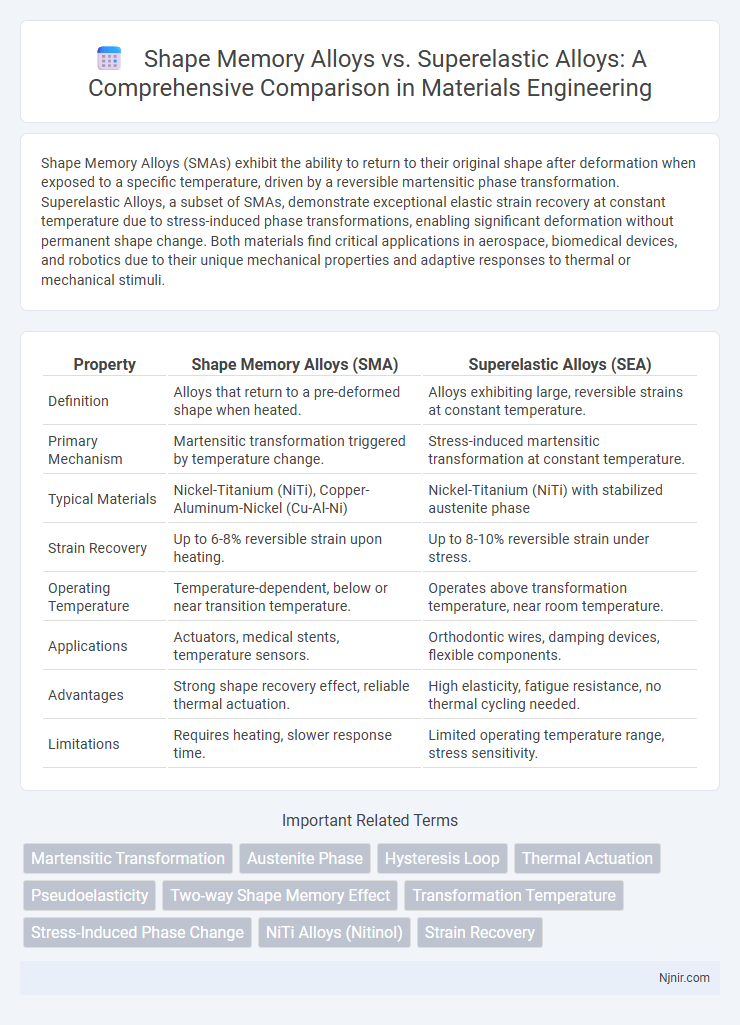

| Property | Shape Memory Alloys (SMA) | Superelastic Alloys (SEA) |

|---|---|---|

| Definition | Alloys that return to a pre-deformed shape when heated. | Alloys exhibiting large, reversible strains at constant temperature. |

| Primary Mechanism | Martensitic transformation triggered by temperature change. | Stress-induced martensitic transformation at constant temperature. |

| Typical Materials | Nickel-Titanium (NiTi), Copper-Aluminum-Nickel (Cu-Al-Ni) | Nickel-Titanium (NiTi) with stabilized austenite phase |

| Strain Recovery | Up to 6-8% reversible strain upon heating. | Up to 8-10% reversible strain under stress. |

| Operating Temperature | Temperature-dependent, below or near transition temperature. | Operates above transformation temperature, near room temperature. |

| Applications | Actuators, medical stents, temperature sensors. | Orthodontic wires, damping devices, flexible components. |

| Advantages | Strong shape recovery effect, reliable thermal actuation. | High elasticity, fatigue resistance, no thermal cycling needed. |

| Limitations | Requires heating, slower response time. | Limited operating temperature range, stress sensitivity. |

Introduction to Shape Memory Alloys (SMAs) and Superelastic Alloys

Shape Memory Alloys (SMAs) are metallic materials that recover their original shape after deformation when exposed to specific temperature changes, exhibiting a thermally induced phase transformation between martensite and austenite. Superelastic Alloys demonstrate a similar reversible deformation but rely on stress-induced phase transformation at a constant temperature above the austenite finish temperature, enabling large strains without permanent shape change. Both materials find crucial applications in biomedical devices, actuators, and sensors, leveraging their unique phase transformation properties.

Fundamental Material Properties

Shape Memory Alloys (SMAs) exhibit a reversible phase transformation between martensite and austenite phases, enabling them to return to a predefined shape after deformation. Superelastic Alloys (SEAs), a subset of SMAs, display large recoverable strains up to 8% due to stress-induced phase transformation without permanent deformation. The fundamental difference lies in temperature dependence: SMAs rely on thermal activation for shape recovery, while SEAs recover shape solely through mechanical loading and unloading within a specific temperature range above the austenite finish temperature.

Phase Transformation Mechanisms

Shape Memory Alloys (SMAs) undergo a reversible phase transformation between martensite and austenite phases, enabling them to recover their original shape upon heating after deformation. Superelastic Alloys exhibit stress-induced phase transformation at a constant temperature, where applied stress causes austenite to transform into martensite, allowing large strains to recover immediately upon unloading. Both mechanisms rely on diffusionless solid-state phase transformations but differ in their activation triggers: thermal cycling for SMAs and mechanical stress for superelastic alloys.

Composition and Alloying Elements

Shape Memory Alloys (SMAs) primarily consist of nickel-titanium (NiTi) with specific ratios of nickel (typically 55-60%) and titanium, enhanced by alloying elements such as copper, iron, and cobalt to improve transformation temperatures and mechanical properties. Superelastic Alloys share a similar NiTi base but are optimized for higher nickel content (around 55-58%) to promote reversible, stress-induced martensitic transformations without permanent deformation. The precise control of alloying elements like niobium and zirconium in both SMAs and superelastic alloys tailors phase transformation behavior, fatigue resistance, and functional stability critical for biomedical and aerospace applications.

Distinguishing Shape Memory Effect vs Superelasticity

Shape Memory Alloys (SMAs) exhibit the Shape Memory Effect, enabling them to return to a predetermined shape upon heating after deformation. Superelastic Alloys demonstrate superelasticity, characterized by large, reversible strains at constant temperature due to stress-induced phase transformation without permanent deformation. The key distinction lies in SMAs requiring a temperature change to recover shape, while superelastic alloys recover shape immediately after unloading at a constant temperature.

Mechanical Performance Comparison

Shape Memory Alloys (SMAs) exhibit superior energy absorption and recoverable strain, typically up to 8%, compared to Superelastic Alloys (SEAs), which demonstrate higher elasticity with recoverable strains up to 10-15%. SMAs show excellent damping capacity and cyclic stability due to their phase transformation under mechanical loading, whereas SEAs offer enhanced flexibility and fatigue resistance, benefiting applications requiring repeated deformation. Mechanical performance evaluations reveal SMAs are ideal for impact and vibration control, while SEAs excel in applications demanding high strain recovery and resilience.

Fatigue Resistance and Durability

Shape memory alloys (SMAs) exhibit high fatigue resistance due to their ability to recover large strains through phase transformations, enabling repeated deformation without permanent damage. Superelastic alloys, a subset of SMAs, display superior durability under cyclic loading by reversing stress-induced martensitic transformations, which enhances their lifespan in applications involving dynamic stresses. Both materials maintain structural integrity under repeated mechanical loading, but superelastic alloys generally outperform conventional SMAs in fatigue resistance due to their enhanced reversible deformation mechanisms.

Common Applications in Industry

Shape memory alloys (SMAs) and superelastic alloys are widely utilized in aerospace, biomedical devices, and robotics due to their unique mechanical properties. SMAs are commonly applied in stents, actuators, and temperature-responsive valves, leveraging their ability to return to a predefined shape after deformation. Superelastic alloys find extensive use in orthodontic wires, seismic dampers, and flexible couplings, where high elasticity and energy absorption are critical for functionality.

Design Considerations and Limitations

Shape Memory Alloys (SMAs) provide significant benefits in design due to their ability to return to a pre-defined shape after deformation, making them ideal for actuators and adaptive structures; however, their performance depends heavily on temperature thresholds and cyclic fatigue resistance. Superelastic Alloys exhibit large reversible strains under mechanical loading without a temperature change, offering advantages in applications requiring flexibility and high strain accommodation but are limited by their lower stress plateau compared to SMAs. Designers must balance these materials' transformation behavior, mechanical properties, and environmental sensitivities to optimize performance and longevity in specific engineering applications.

Future Trends in Alloy Development

Advancements in Shape Memory Alloys (SMAs) and Superelastic Alloys (SEAs) are driven by the development of high-performance materials with enhanced fatigue resistance and tailored transformation temperatures. Emerging trends emphasize alloy compositions such as NiTi-based variants with added elements like copper or iron to improve mechanical properties and thermal stability. Research also focuses on scalable manufacturing techniques and smart material integration for aerospace, biomedical, and robotics applications.

Martensitic Transformation

Shape memory alloys exhibit reversible martensitic transformation enabling shape recovery upon heating, while superelastic alloys undergo stress-induced martensitic transformation that allows large, recoverable strains without temperature change.

Austenite Phase

Austenite phase in Shape Memory Alloys ensures reversible phase transformation for thermal actuation, while in Superelastic Alloys it enables stress-induced reversible deformation at constant temperature.

Hysteresis Loop

Shape Memory Alloys exhibit a wider hysteresis loop due to phase transformation between martensite and austenite, while Superelastic Alloys display a narrower hysteresis loop characterized by reversible stress-induced austenite-martensite transformation.

Thermal Actuation

Shape Memory Alloys exhibit thermal actuation by recovering pre-deformed shapes upon heating due to phase transformation, while Superelastic Alloys rely on stress-induced phase changes at constant temperature without thermal activation.

Pseudoelasticity

Superelastic alloys exhibit pronounced pseudoelasticity, allowing reversible large strains through stress-induced phase transformation, whereas shape memory alloys primarily rely on temperature-driven phase changes for the shape memory effect.

Two-way Shape Memory Effect

Two-way shape memory alloys exhibit reversible strain changes with temperature fluctuations, unlike superelastic alloys that primarily demonstrate stress-induced reversible deformation without temperature-dependent memory.

Transformation Temperature

Shape memory alloys exhibit transformation temperatures generally above room temperature for phase change, while superelastic alloys transform at or just below room temperature, enabling reversible deformation without permanent shape change.

Stress-Induced Phase Change

Shape memory alloys undergo reversible martensitic phase transformations under mechanical stress enabling shape recovery, while superelastic alloys exhibit stress-induced phase changes that allow large elastic deformations without permanent shape alteration.

NiTi Alloys (Nitinol)

NiTi alloys (Nitinol) exhibit distinct properties where shape memory alloys recover original shape after heating, while superelastic alloys demonstrate reversible strain through stress-induced phase transformation at constant temperature.

Strain Recovery

Shape Memory Alloys exhibit strain recovery through a reversible martensitic transformation enabling shape restoration upon heating, while Superelastic Alloys recover strain instantly through stress-induced phase transformation without temperature change.

Shape Memory Alloys vs Superelastic Alloys Infographic

njnir.com

njnir.com