Smart materials possess the unique ability to respond to environmental stimuli such as temperature, pressure, or electric fields, enabling adaptive functionality that traditional materials lack. These materials offer enhanced performance through properties like self-healing, shape memory, and sensing capabilities, which improve durability and efficiency in engineering applications. Unlike conventional materials that remain passive, smart materials facilitate innovation in fields ranging from aerospace to biomedical engineering by dynamically interacting with their surroundings.

Table of Comparison

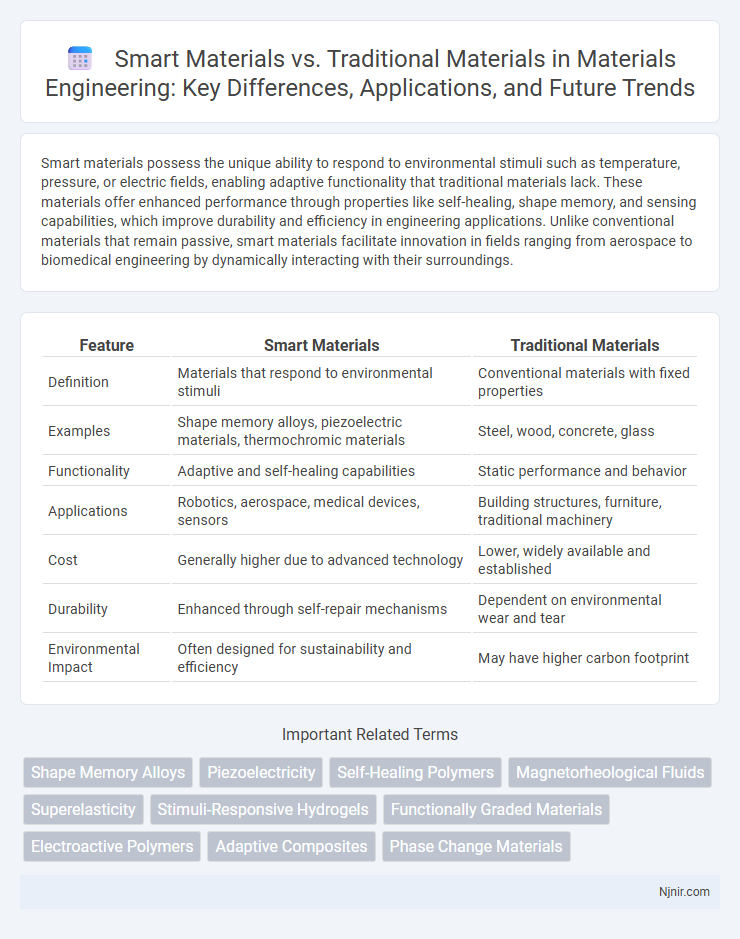

| Feature | Smart Materials | Traditional Materials |

|---|---|---|

| Definition | Materials that respond to environmental stimuli | Conventional materials with fixed properties |

| Examples | Shape memory alloys, piezoelectric materials, thermochromic materials | Steel, wood, concrete, glass |

| Functionality | Adaptive and self-healing capabilities | Static performance and behavior |

| Applications | Robotics, aerospace, medical devices, sensors | Building structures, furniture, traditional machinery |

| Cost | Generally higher due to advanced technology | Lower, widely available and established |

| Durability | Enhanced through self-repair mechanisms | Dependent on environmental wear and tear |

| Environmental Impact | Often designed for sustainability and efficiency | May have higher carbon footprint |

Introduction to Smart and Traditional Materials

Smart materials respond dynamically to external stimuli such as temperature, pressure, or electric fields, enabling adaptive functionality in engineering and biomedical applications. Traditional materials like metals, ceramics, and polymers exhibit static properties, lacking the ability to change their characteristics actively. The evolution from traditional to smart materials marks a shift towards innovation in material science, emphasizing responsiveness, self-healing, and energy efficiency.

Evolution of Materials in Engineering

Smart materials, such as shape memory alloys, piezoelectric materials, and self-healing polymers, represent a significant evolution in engineering by offering adaptive responses to environmental stimuli like temperature, stress, or electric fields. Unlike traditional materials, which have fixed properties, smart materials improve structural performance, durability, and functionality through their ability to sense and react to changes. This advancement accelerates innovation in fields including aerospace, biomedical devices, and civil engineering by enhancing system efficiency and reducing maintenance costs.

Key Properties: Traditional vs. Smart Materials

Traditional materials primarily exhibit fixed properties such as strength, durability, and thermal stability, which remain constant under varying conditions. Smart materials possess adaptive characteristics, responding dynamically to environmental stimuli like temperature, pressure, or electric fields with changes in shape, color, or conductivity. These responsive properties enable smart materials to outperform traditional materials in applications requiring real-time adaptability and multifunctionality.

Mechanisms of Smart Material Functionality

Smart materials function through mechanisms such as shape memory, piezoelectricity, and magnetorheology, responding dynamically to external stimuli like temperature, stress, or electromagnetic fields. Traditional materials rely on fixed physical and chemical properties without adaptive responses, limiting their functionality to static conditions. The microstructural changes within smart materials enable reversible transformations, providing advantages in applications requiring self-healing, sensing, or actuation capabilities.

Common Applications of Traditional Materials

Traditional materials such as steel, wood, concrete, and glass are widely used in construction, automotive manufacturing, and infrastructure projects due to their proven durability and cost-effectiveness. These materials serve as fundamental components in buildings, bridges, furniture, and transportation vehicles, providing structural integrity and aesthetic appeal. The extensive supply chain and familiarity with manufacturing processes make traditional materials a reliable choice for large-scale industrial and residential applications.

Innovative Uses for Smart Materials

Smart materials offer innovative uses that traditional materials cannot match, such as self-healing polymers that repair damage autonomously and shape-memory alloys that change form in response to temperature. These materials are integral to advanced applications in aerospace, biomedical devices, and wearable technology, enabling enhanced performance and adaptive functionality. Integration of piezoelectric materials in sensors and actuators exemplifies the significant advancements driving smarter, more efficient designs compared to static traditional materials.

Advantages and Limitations of Traditional Materials

Traditional materials like steel, wood, and concrete offer proven durability, cost-effectiveness, and widespread availability, making them reliable choices for many construction and manufacturing applications. However, these materials often lack adaptability, self-healing properties, and responsiveness to environmental changes, limiting their performance in advanced technological applications. Their higher maintenance requirements and inability to optimize functionality under varying conditions contrast with the dynamic capabilities of smart materials.

Benefits and Challenges of Smart Materials

Smart materials offer significant benefits over traditional materials, including self-healing properties, adaptability to environmental changes, and enhanced durability, leading to reduced maintenance costs and longer service life. They enable applications in aerospace, healthcare, and construction by responding dynamically to stress, temperature, or electric fields, which traditional materials cannot achieve. Challenges of smart materials include higher production costs, complex integration into existing systems, and limited long-term reliability data compared to well-established traditional materials.

Comparative Case Studies: Smart vs. Traditional Solutions

Comparative case studies reveal that smart materials, such as shape-memory alloys and piezoelectric sensors, outperform traditional materials in adaptive functionality and self-healing capabilities, resulting in enhanced durability and reduced maintenance costs. In structural engineering, smart concrete embedded with sensors provides real-time health monitoring, unlike conventional concrete that relies on periodic manual inspections. These advancements highlight smart materials' superior efficiency and sustainability in applications ranging from aerospace to civil infrastructure.

Future Trends in Material Engineering

Smart materials, characterized by their ability to respond to environmental stimuli such as temperature, pressure, and electric fields, are revolutionizing material engineering by enabling adaptive and multifunctional applications. Future trends highlight the integration of nanotechnology and artificial intelligence to enhance the responsiveness and durability of these materials, surpassing the limitations of traditional materials like metals, ceramics, and polymers. Advances in self-healing composites, shape-memory alloys, and piezoelectric materials promise to drive innovations in aerospace, healthcare, and sustainable construction industries.

Shape Memory Alloys

Shape Memory Alloys, a type of smart material, outperform traditional materials by exhibiting the unique ability to return to their original shape after deformation when exposed to specific temperatures.

Piezoelectricity

Piezoelectric smart materials generate electric charge under mechanical stress, offering precise sensing and energy harvesting capabilities unlike traditional materials that lack this property.

Self-Healing Polymers

Self-healing polymers, a type of smart material, autonomously repair damage by restoring their mechanical properties, unlike traditional materials that require external intervention for maintenance and repair.

Magnetorheological Fluids

Magnetorheological fluids in smart materials exhibit rapid viscosity changes under magnetic fields, offering superior adaptive damping and control compared to traditional materials' static properties.

Superelasticity

Smart materials exhibit superior superelasticity by undergoing reversible strain up to 8% without permanent deformation, whereas traditional materials typically fail or deform irreversibly beyond 0.2% strain.

Stimuli-Responsive Hydrogels

Stimuli-responsive hydrogels, a type of smart material, undergo reversible physical or chemical changes in response to environmental stimuli such as pH, temperature, or light, offering advanced applications beyond the static properties of traditional materials.

Functionally Graded Materials

Functionally Graded Materials (FGMs) offer superior performance by gradually varying composition and structure to optimize mechanical, thermal, and chemical properties compared to uniform traditional materials.

Electroactive Polymers

Electroactive polymers offer superior flexibility, rapid response, and high deformability compared to traditional materials, making them ideal for applications in actuators, sensors, and artificial muscles.

Adaptive Composites

Adaptive composites in smart materials dynamically respond to environmental changes, offering superior performance and multifunctionality compared to static traditional materials.

Phase Change Materials

Phase Change Materials (PCMs) outperform traditional materials by efficiently storing and releasing thermal energy through reversible phase transitions, enhancing energy management in building insulation and temperature regulation applications.

Smart materials vs Traditional materials Infographic

njnir.com

njnir.com