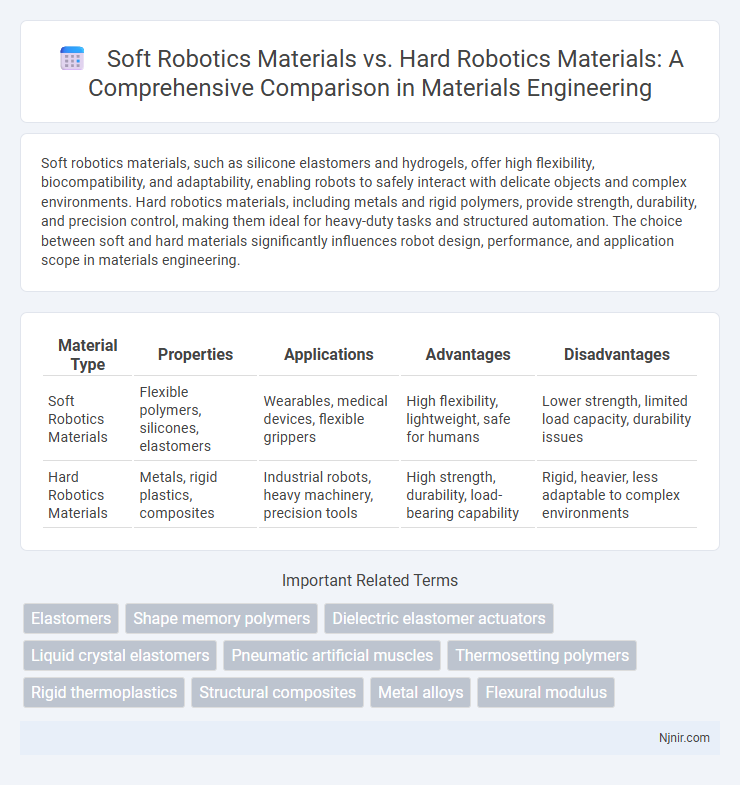

Soft robotics materials, such as silicone elastomers and hydrogels, offer high flexibility, biocompatibility, and adaptability, enabling robots to safely interact with delicate objects and complex environments. Hard robotics materials, including metals and rigid polymers, provide strength, durability, and precision control, making them ideal for heavy-duty tasks and structured automation. The choice between soft and hard materials significantly influences robot design, performance, and application scope in materials engineering.

Table of Comparison

| Material Type | Properties | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Soft Robotics Materials | Flexible polymers, silicones, elastomers | Wearables, medical devices, flexible grippers | High flexibility, lightweight, safe for humans | Lower strength, limited load capacity, durability issues |

| Hard Robotics Materials | Metals, rigid plastics, composites | Industrial robots, heavy machinery, precision tools | High strength, durability, load-bearing capability | Rigid, heavier, less adaptable to complex environments |

Introduction to Soft and Hard Robotics Materials

Soft robotics materials, such as silicones, hydrogels, and elastomers, provide flexibility, compliance, and adaptability, enabling robots to perform delicate tasks and navigate unstructured environments. Hard robotics materials typically include metals like aluminum and steel, as well as rigid plastics, offering high strength, durability, and precision for tasks demanding structural stability and heavy load-bearing. Understanding the fundamental differences in material properties drives the selection of appropriate components for specific robotic applications and operational requirements.

Fundamental Differences: Soft vs Hard Robotics Materials

Soft robotics materials are typically composed of elastomers, silicones, and hydrogels that provide high flexibility, compliance, and the ability to undergo large deformations. Hard robotics materials consist of metals, rigid plastics, and composites, offering high strength, dimensional stability, and precise control over movement. The fundamental difference lies in the trade-off between adaptability in soft materials and robustness in hard materials, influencing design choices across diverse applications such as delicate object manipulation and heavy-load handling.

Mechanical Properties Comparison

Soft robotics materials, such as silicones, elastomers, and hydrogels, exhibit high elasticity, flexibility, and deformability, enabling adaptive movements and safe human-robot interaction. Hard robotics materials, including metals like aluminum and steel, offer superior tensile strength, stiffness, and durability, providing precise control and load-bearing capabilities. The mechanical property contrast lies primarily in softness and compliance for soft materials versus rigidity and strength for hard materials, influencing their respective applications and performance in robotics systems.

Material Selection Criteria for Robotics

Material selection criteria for robotics prioritize flexibility, durability, and functionality tailored to application needs. Soft robotics materials, such as silicones, elastomers, and hydrogels, offer high elasticity and compliance essential for safe human interaction, adaptive gripping, and bio-inspired movements. Hard robotics materials like aluminum, steel, and rigid polymers provide structural strength, high load-bearing capacity, and precision, crucial for tasks requiring rigidity and accuracy in industrial automation.

Fabrication Techniques for Soft and Hard Robotics

Soft robotics materials rely on fabrication techniques such as molding, casting, and 3D printing of elastomers like silicone and hydrogels, enabling flexible, compliant structures essential for adaptive functions. Hard robotics materials utilize machining, metal casting, and additive manufacturing with rigid materials such as metals and hard plastics to achieve high strength, precision, and structural stability. Advances in multi-material printing and hybrid fabrication processes are bridging the gap, allowing integration of soft and hard components to optimize performance in robotic systems.

Performance in Real-World Applications

Soft robotics materials, such as silicone elastomers and hydrogels, provide exceptional flexibility, adaptability, and safe human interaction, making them ideal for applications like medical devices and wearable technology. Hard robotics materials, including metals and rigid plastics, excel in strength, precision, and durability, which are critical for heavy-duty industrial tasks and automated manufacturing. Performance in real-world applications depends on choosing materials aligned with the specific requirements of flexibility versus load-bearing capacity and environmental resistance.

Versatility and Adaptability in Robotics Tasks

Soft robotics materials like silicone, elastomers, and hydrogels offer superior versatility and adaptability by enabling robots to safely interact with irregular, fragile, or dynamic environments through flexible, deformable structures. In contrast, hard robotics materials such as metals and rigid plastics provide strength and precision but lack the compliance needed for delicate manipulation and rapid shape changes. This fundamental difference in material properties directly influences a robot's ability to perform diverse, unstructured tasks and adapt to varying operational conditions.

Durability and Lifespan Analysis

Soft robotics materials, such as silicone, elastomers, and hydrogels, offer flexibility and adaptability but generally exhibit lower durability and shorter lifespan due to susceptibility to wear, fatigue, and environmental degradation. Hard robotics materials, including metals like aluminum and steel, as well as rigid polymers, provide superior mechanical strength, higher resistance to abrasion, and longer operational lifespan under harsh conditions. Lifecycle analysis reveals that while soft materials excel in applications requiring compliance, hard materials dominate in durability-critical tasks with extended service requirements.

Recent Advances in Soft and Hard Robotics Materials

Recent advances in soft robotics materials emphasize flexible polymers, hydrogels, and shape-memory alloys that enhance adaptability and safe human interaction, while hard robotics materials primarily involve high-strength metals, composites, and advanced ceramics improving durability and precision. Innovations in stimuli-responsive elastomers enable soft robots to mimic biological movements, contrasting with hard robotics' integration of lightweight titanium alloys and carbon fiber composites for structural rigidity. These developments redefine performance benchmarks in robotics across medical, industrial, and exploratory applications.

Future Trends and Innovations in Robotic Materials

Future trends in soft robotics materials emphasize stretchable, self-healing polymers and bio-compatible hydrogels that mimic natural tissues to enhance adaptability and safety in human-robot interaction. Innovations in hard robotics materials focus on ultra-lightweight, high-strength composites and smart metals with embedded sensors, improving durability and precision for demanding industrial applications. Advancements in hybrid materials integrating softness and rigidity enable versatile robots capable of complex tasks in dynamic environments.

Elastomers

Elastomers in soft robotics offer flexible, stretchable, and durable properties essential for adaptive movements, contrasting with rigid, brittle hard robotics materials like metals and plastics that provide structural strength but lack elasticity.

Shape memory polymers

Shape memory polymers in soft robotics offer enhanced flexibility and adaptability compared to the rigid, durable materials typical of hard robotics, enabling more complex, lifelike movements and safer human-robot interactions.

Dielectric elastomer actuators

Dielectric elastomer actuators in soft robotics offer superior flexibility, lightweight properties, and high strain capabilities compared to rigid materials used in hard robotics, enabling safer, more adaptable, and energy-efficient actuation.

Liquid crystal elastomers

Liquid crystal elastomers in soft robotics offer flexible, shape-changing properties that enable adaptive, bioinspired movement unlike rigid, durable materials used in hard robotics.

Pneumatic artificial muscles

Pneumatic artificial muscles in soft robotics utilize flexible, lightweight elastomers to mimic natural muscle movements, contrasting with the rigid metals and composites used in hard robotics materials for strength and durability.

Thermosetting polymers

Thermosetting polymers in soft robotics provide superior flexibility and resilience compared to the rigid, durable thermoplastic and metal materials used in hard robotics.

Rigid thermoplastics

Rigid thermoplastics in hard robotics materials provide enhanced durability and structural strength compared to the flexible, compliant polymers commonly used in soft robotics materials, enabling precise movement and heavy-load handling.

Structural composites

Soft robotics materials leverage flexible structural composites like silicone-based elastomers and shape-memory polymers, offering adaptability and resilience, whereas hard robotics materials rely on rigid composites such as carbon fiber-reinforced polymers for strength and precision.

Metal alloys

Metal alloys in hard robotics materials offer superior strength and durability compared to the flexible, adaptive polymers used in soft robotics materials.

Flexural modulus

Soft robotics materials typically exhibit a low flexural modulus ranging from 0.01 to 10 MPa, enabling high flexibility and deformation, whereas hard robotics materials possess a significantly higher flexural modulus, often exceeding 1 GPa, providing structural rigidity and load-bearing capacity.

Soft robotics materials vs Hard robotics materials Infographic

njnir.com

njnir.com