Carbon fiber exhibits exceptional stiffness and tensile strength, making it ideal for high-performance structural applications, while Kevlar offers superior impact resistance and flexibility, enhancing ballistic protection and durability. The lightweight nature of both materials contributes to their widespread use in aerospace, automotive, and sports equipment industries. Selecting between carbon fiber and Kevlar depends on whether rigidity or toughness is the primary engineering requirement.

Table of Comparison

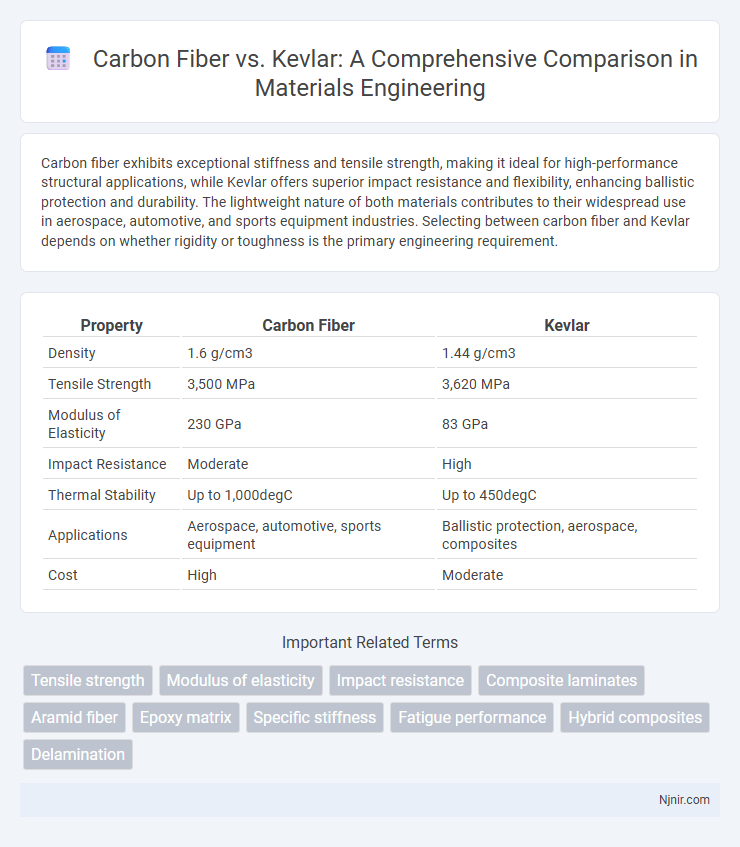

| Property | Carbon Fiber | Kevlar |

|---|---|---|

| Density | 1.6 g/cm3 | 1.44 g/cm3 |

| Tensile Strength | 3,500 MPa | 3,620 MPa |

| Modulus of Elasticity | 230 GPa | 83 GPa |

| Impact Resistance | Moderate | High |

| Thermal Stability | Up to 1,000degC | Up to 450degC |

| Applications | Aerospace, automotive, sports equipment | Ballistic protection, aerospace, composites |

| Cost | High | Moderate |

Introduction to Carbon Fiber and Kevlar

Carbon fiber is a lightweight, high-strength material composed of thin strands of carbon atoms tightly woven into a fabric and bonded with resin, known for its exceptional stiffness and tensile strength. Kevlar, a synthetic aramid fiber, is valued for its outstanding impact resistance and ability to absorb energy, making it ideal for ballistic and protective applications. Both materials are widely used in aerospace, automotive, and sports industries for their unique mechanical properties and durability.

Composition and Manufacturing Processes

Carbon fiber consists primarily of thin strands of carbon atoms bonded in a crystalline structure, produced through the pyrolysis of polyacrylonitrile (PAN) or pitch precursor materials under high temperatures. Kevlar, a para-aramid synthetic fiber, is formed through the polymerization of aromatic polyamides and spun into fibers using a wet-spinning process. The manufacturing of carbon fiber involves oxidation, carbonization, and surface treatment to enhance strength and stiffness, while Kevlar fibers undergo precise control of polymer orientation and heat treatment to maximize tensile strength and impact resistance.

Mechanical Properties Comparison

Carbon fiber exhibits exceptional tensile strength of up to 7,000 MPa and a high modulus of elasticity around 230 GPa, making it ideal for applications requiring rigidity and minimal weight. Kevlar provides superior impact resistance with tensile strength near 3,620 MPa and excellent toughness, allowing it to absorb and dissipate energy effectively. While carbon fiber is stiffer and excels in load-bearing roles, Kevlar offers greater flexibility and durability in environments subjected to dynamic forces and abrasion.

Weight and Density Differences

Carbon fiber has a density of approximately 1.6 g/cm3, making it significantly lighter than Kevlar, which has a density around 1.44 g/cm3 but often results in heavier composite materials due to resin absorption and weave tightness. Despite its slightly higher density, Kevlar offers superior impact resistance and toughness, while carbon fiber's lower weight and stiffness make it preferred for applications demanding lightweight and high-strength structures. The choice between carbon fiber and Kevlar depends largely on the balance between weight efficiency and durability requirements.

Impact Resistance and Toughness

Carbon fiber exhibits high tensile strength but tends to be brittle, making it less effective at absorbing impact energy compared to Kevlar. Kevlar's exceptional toughness and energy absorption capabilities provide superior impact resistance, especially in ballistic and protective applications. Its ability to deform without breaking under intense stress makes Kevlar a preferred choice for impact-heavy environments.

Thermal and Chemical Stability

Carbon fiber exhibits superior thermal stability, maintaining structural integrity at temperatures above 3,000degF (1,650degC), while Kevlar begins to degrade around 800degF (427degC). Chemically, carbon fiber resists corrosion and most solvents, making it highly durable in harsh environments, whereas Kevlar is vulnerable to strong acids and bases, limiting its chemical resistance. These differences make carbon fiber more suitable for high-temperature industrial applications and chemically aggressive conditions compared to Kevlar.

Applications in Industry

Carbon fiber is widely utilized in aerospace and automotive industries due to its exceptional strength-to-weight ratio and rigidity, enhancing performance and fuel efficiency. Kevlar is preferred in military and protective equipment manufacturing because of its superior impact resistance and ballistic protection properties. Both materials find applications in sporting goods and construction, with carbon fiber offering lightweight stiffness and Kevlar providing toughness and flexibility.

Cost and Availability Analysis

Carbon fiber typically commands a higher price due to its complex manufacturing process and limited raw material supply, impacting its availability especially in large-scale production. Kevlar offers a more cost-effective alternative with widespread availability, as its production relies on more readily accessible polyamide fibers and established manufacturing infrastructure. The price difference influences material selection across industries, where budget constraints and supply chain reliability are critical factors.

Environmental Impact and Sustainability

Carbon fiber, derived from petroleum, has a high energy-intensive production process that results in significant carbon emissions, while Kevlar, made from aromatic polyamides, generates less environmental pollution during manufacturing. Both materials are non-biodegradable and challenging to recycle, but Kevlar's lower energy demand and potential for repurposing make it a relatively more sustainable choice. Innovations in bio-based precursors and recycling technologies are critical to reducing the environmental footprint of carbon fiber and Kevlar composites in the future.

Future Trends and Innovations

Emerging innovations in carbon fiber focus on enhancing its strength-to-weight ratio and improving sustainability through recycled composites. Kevlar advancements target increased thermal resistance and integration with nanomaterials for superior impact protection. Future trends indicate hybrid composites combining carbon fiber and Kevlar to optimize performance across aerospace, automotive, and defense industries.

Tensile strength

Carbon fiber exhibits a tensile strength of approximately 4,000 MPa, significantly surpassing Kevlar's tensile strength of around 3,620 MPa, making carbon fiber the preferred material for applications requiring superior resistance to stretching forces.

Modulus of elasticity

Carbon fiber exhibits a higher modulus of elasticity, typically around 230-600 GPa, compared to Kevlar's modulus of approximately 70-112 GPa, making carbon fiber stiffer and more suitable for applications requiring greater rigidity.

Impact resistance

Kevlar offers superior impact resistance compared to carbon fiber due to its exceptional tensile strength and energy absorption properties.

Composite laminates

Carbon fiber composite laminates offer superior tensile strength and stiffness, while Kevlar laminates provide enhanced impact resistance and toughness for diverse engineering applications.

Aramid fiber

Aramid fibers, including Kevlar, offer superior impact resistance and tensile strength compared to carbon fiber, making them ideal for ballistic protection and flexible composite applications.

Epoxy matrix

Carbon fiber reinforced with an epoxy matrix offers superior tensile strength and stiffness compared to Kevlar composites, which provide enhanced impact resistance and flexibility when combined with the same epoxy resin.

Specific stiffness

Carbon fiber exhibits higher specific stiffness than Kevlar, making it more suitable for applications requiring lightweight materials with exceptional rigidity.

Fatigue performance

Carbon fiber exhibits superior fatigue resistance with higher endurance limits compared to Kevlar, making it more durable under cyclic loading conditions.

Hybrid composites

Hybrid composites combining carbon fiber and Kevlar optimize strength, impact resistance, and lightweight performance for aerospace and automotive applications.

Delamination

Carbon fiber exhibits higher stiffness but is more prone to delamination under impact, whereas Kevlar offers superior delamination resistance due to its excellent toughness and energy absorption properties.

Carbon Fiber vs Kevlar Infographic

njnir.com

njnir.com