Porosity and density are inversely related physical properties critical to materials engineering, impacting mechanical strength and durability. High porosity indicates greater void spaces within a material, leading to lower density and reduced load-bearing capacity. Optimizing the balance between porosity and density is essential for tailoring materials to specific applications such as lightweight composites or structural components.

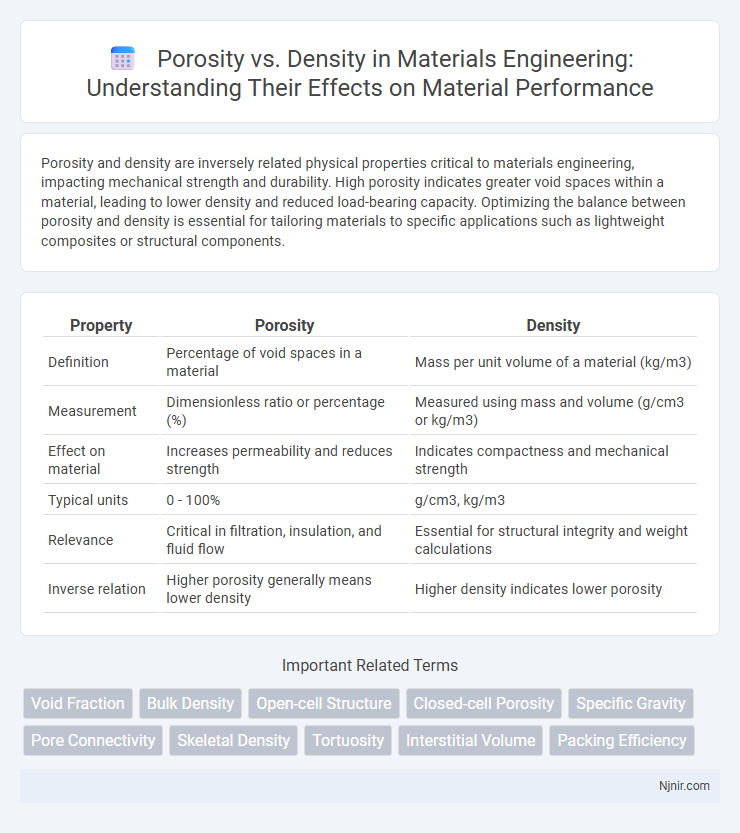

Table of Comparison

| Property | Porosity | Density |

|---|---|---|

| Definition | Percentage of void spaces in a material | Mass per unit volume of a material (kg/m3) |

| Measurement | Dimensionless ratio or percentage (%) | Measured using mass and volume (g/cm3 or kg/m3) |

| Effect on material | Increases permeability and reduces strength | Indicates compactness and mechanical strength |

| Typical units | 0 - 100% | g/cm3, kg/m3 |

| Relevance | Critical in filtration, insulation, and fluid flow | Essential for structural integrity and weight calculations |

| Inverse relation | Higher porosity generally means lower density | Higher density indicates lower porosity |

Introduction to Porosity and Density

Porosity refers to the percentage of void spaces within a material, determining its capacity to hold fluids or gases, while density measures the mass per unit volume, indicating how compact a material is. High porosity often results in lower density since the material contains more empty spaces, whereas low porosity corresponds to higher density due to closely packed particles. Understanding the relationship between porosity and density is crucial in fields like geology, material science, and engineering for assessing material strength, fluid flow, and storage capabilities.

Fundamental Definitions: Porosity and Density

Porosity is the measure of void spaces in a material, defined as the ratio of the volume of these voids to the total volume, usually expressed as a percentage. Density refers to the mass of a material per unit volume, commonly measured in kilograms per cubic meter (kg/m3). While porosity indicates the capacity of a material to hold fluids, density provides insights into its compactness and overall mass distribution.

Methods of Measuring Porosity

Porosity measurement methods primarily include mercury intrusion porosimetry, gas adsorption techniques, and nuclear magnetic resonance (NMR) porosity. Mercury intrusion porosimetry quantifies pore volume by measuring mercury displacement under controlled pressure, yielding high-resolution data on pore size distribution. Gas adsorption methods, such as the Brunauer-Emmett-Teller (BET) technique, assess surface area and pore volume by gas uptake, while NMR determines porosity by analyzing hydrogen nuclei in pore fluids, providing non-destructive and accurate density-related porosity estimations.

Techniques for Determining Density

Techniques for determining density often include the Archimedes principle, which measures the volume of displaced fluid to calculate the density of solids. Helium pycnometry provides highly accurate volume measurements by assessing gas displacement, ideal for porous materials. X-ray computed tomography offers non-destructive density mapping by creating 3D images that reveal internal structure variations related to porosity and density.

Relationship Between Porosity and Density

Porosity and density have an inverse relationship where increased porosity typically results in decreased bulk density due to the larger volume of void spaces within a material. Theoretical density remains constant, but bulk density varies as porosity alters the effective volume occupied by solid matter. Understanding this relationship is crucial in fields like geology, materials science, and soil mechanics for predicting permeability and strength.

Impact of Porosity on Material Properties

Porosity significantly affects the density of materials by introducing void spaces that reduce overall mass per unit volume, leading to lower density values. High porosity typically decreases mechanical strength, thermal conductivity, and electrical resistivity, impacting the material's structural integrity and performance. Understanding the relationship between porosity and density is crucial for optimizing materials in applications such as ceramics, polymers, and metal foams where specific mechanical and physical properties are required.

Influence of Density on Mechanical Strength

In materials science, density directly impacts mechanical strength by influencing the porosity level within a material's structure. Higher density typically corresponds to lower porosity, resulting in fewer voids and defects that can act as stress concentrators, thereby enhancing the material's load-bearing capacity and resistance to fracture. Metals, ceramics, and composites exhibit improved tensile strength and hardness with increased density as the atomic packing becomes more uniform and compact.

Applications Requiring Specific Porosity-Density Ratios

Porosity and density are critical parameters in materials science, affecting applications such as filtration, insulation, and catalyst supports where specific porosity-density ratios determine performance efficiency. High porosity with moderate density is essential in lightweight thermal insulators to trap air while maintaining structural integrity. Conversely, low porosity combined with high density is preferred in load-bearing components to ensure mechanical strength and durability.

Case Studies in Materials Engineering

Case studies in materials engineering reveal that porosity inversely affects density, as demonstrated in lightweight metal foams where increased pore volume significantly reduces overall material density while maintaining structural integrity. In aerospace composites, controlled porosity enables tailored density profiles, optimizing strength-to-weight ratios crucial for performance and fuel efficiency. Research on ceramics shows that precise manipulation of porosity enhances properties like thermal insulation and mechanical toughness without compromising density beyond application-specific thresholds.

Advances and Future Trends in Porosity-Density Research

Recent advances in porosity-density research emphasize the development of nanoscale characterization techniques such as X-ray computed tomography and atomic force microscopy, enabling more accurate measurement of pore structures and material density. Integration of machine learning algorithms with experimental data accelerates the prediction of porous material behavior under various environmental conditions, optimizing performance in industries like energy storage and filtration. Future trends point to the synthesis of multifunctional porous materials with tailored density profiles for applications in lightweight aerospace components and high-efficiency catalysts.

Void Fraction

Void fraction represents the ratio of void volume to total volume in a material and directly influences porosity, whereas density measures mass per unit volume and decreases as void fraction increases.

Bulk Density

Bulk density quantifies the mass of soil per unit volume, including pore spaces, directly influencing porosity, which measures the volume of those pores relative to the total soil volume.

Open-cell Structure

Open-cell structure porosity significantly reduces material density by increasing void spaces, enhancing properties like insulation and sound absorption.

Closed-cell Porosity

Closed-cell porosity significantly reduces material density by creating enclosed gas-filled pockets that limit structural mass while enhancing insulation properties.

Specific Gravity

Porosity inversely affects density and specific gravity, where higher porosity decreases specific gravity by increasing void spaces within a material's structure.

Pore Connectivity

Pore connectivity significantly influences porosity and density by determining fluid flow pathways and impacting the material's overall permeability and structural integrity.

Skeletal Density

Skeletal density, defined as the mass of a material divided by the volume excluding pores, directly correlates with porosity since higher porosity results in lower skeletal density values.

Tortuosity

Tortuosity significantly influences porosity and density relationships by increasing the complexity of pore pathways, which reduces permeability despite high porosity levels.

Interstitial Volume

Interstitial volume directly influences porosity by representing the void spaces within a material, which inversely affects density as increased porosity lowers overall density.

Packing Efficiency

Higher packing efficiency decreases porosity and increases density by minimizing void spaces within a material's microstructure.

Porosity vs Density Infographic

njnir.com

njnir.com