Ductility measures a material's ability to undergo significant plastic deformation under tensile stress, enabling it to be drawn into thin wires without breaking. Malleability refers to a material's capacity to deform under compressive stress, allowing it to be hammered or rolled into thin sheets. Both properties are essential for manufacturing processes, but ductility emphasizes tensile stretching while malleability focuses on compressive shaping.

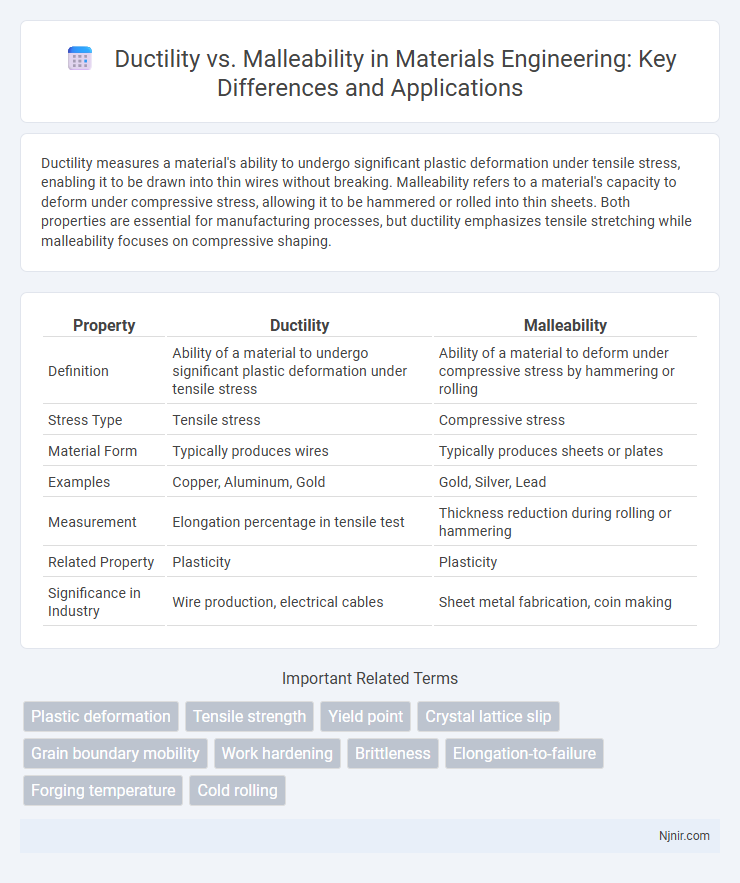

Table of Comparison

| Property | Ductility | Malleability |

|---|---|---|

| Definition | Ability of a material to undergo significant plastic deformation under tensile stress | Ability of a material to deform under compressive stress by hammering or rolling |

| Stress Type | Tensile stress | Compressive stress |

| Material Form | Typically produces wires | Typically produces sheets or plates |

| Examples | Copper, Aluminum, Gold | Gold, Silver, Lead |

| Measurement | Elongation percentage in tensile test | Thickness reduction during rolling or hammering |

| Related Property | Plasticity | Plasticity |

| Significance in Industry | Wire production, electrical cables | Sheet metal fabrication, coin making |

Introduction to Ductility and Malleability

Ductility refers to a material's ability to undergo significant plastic deformation under tensile stress, allowing it to be stretched into thin wires without breaking, which is essential in metalworking and electrical industries. Malleability describes a material's capacity to deform under compressive stress, enabling it to be hammered or rolled into thin sheets, critical in manufacturing and metal forming. Both properties are indicators of a material's plasticity but differ in the type of stress applied and the form of deformation they produce.

Defining Ductility in Materials Engineering

Ductility in materials engineering refers to a material's ability to undergo significant plastic deformation under tensile stress before rupture, enabling it to be drawn into wires. It is quantified by elongation percentage or reduction in area during tensile testing, critical for applications requiring flexibility and toughness. This property contrasts with malleability, which measures a material's capacity to deform under compressive stress, such as hammering or rolling into sheets.

Understanding Malleability: Key Concepts

Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. Unlike ductility, which measures a material's capacity to stretch under tensile stress, malleability emphasizes shape changes under pressure. Key concepts include the atomic structure that enables layers of atoms to slide over each other easily, making metals like gold and aluminum highly malleable for various industrial applications.

Comparative Analysis: Ductility vs Malleability

Ductility refers to a material's ability to undergo significant plastic deformation under tensile stress, allowing it to be drawn into wires, whereas malleability describes a material's capacity to deform under compressive stress, enabling it to be hammered or rolled into thin sheets. Metals like gold exhibit both high ductility and malleability, but ductility is critical in applications requiring wire production, while malleability is essential for manufacturing sheets and foils. Understanding the differences in atomic bonding and crystal structure helps predict the material's behavior under different mechanical forces, influencing material selection in engineering and manufacturing.

Atomic Structure Influence on Ductility and Malleability

Ductility and malleability are influenced significantly by the atomic structure of metals, where atoms arranged in closely packed planes, such as face-centered cubic (FCC) lattices, allow easier atomic slip and deformation. Metals with FCC structures like gold and copper exhibit high ductility and malleability due to multiple slip systems enabling atoms to slide past each other without fracturing. In contrast, hexagonal close-packed (HCP) metals have fewer slip systems, restricting atomic movement and resulting in lower ductility and malleability.

Testing Methods for Ductility and Malleability

Testing methods for ductility primarily include tensile tests, where a material is stretched until it fractures, measuring elongation and reduction in area to evaluate its ability to deform plastically under tensile stress. Malleability is commonly assessed through compressive tests and hammering or rolling simulations, which examine a material's capacity to deform under compressive stress without cracking, reflecting its capability to form thin sheets. Both testing approaches provide essential data for material selection in engineering, manufacturing, and metallurgical processes by quantifying deformation characteristics under different loading conditions.

Material Examples: High Ductility vs High Malleability

Copper exhibits high ductility, allowing it to be drawn into thin wires without breaking, while gold demonstrates exceptional malleability, enabling it to be hammered into extremely thin sheets. Steel also shows notable ductility, used extensively in construction for its ability to undergo significant deformation before failure. In contrast, lead is highly malleable, often utilized in applications requiring shaping into intricate forms without cracking.

Industrial Applications Based on Mechanical Properties

Ductility enables metals like copper and aluminum to be drawn into wires, essential for electrical and telecommunications industries, while malleability allows metals such as gold and lead to be shaped into thin sheets for manufacturing components in automotive and packaging sectors. The mechanical properties of ductility and malleability directly influence material selection in industrial applications, as high ductility ensures resistance to fracture during forming processes, and high malleability permits extensive deformation without cracking, critical for processes like rolling and forging. Understanding the balance between these properties allows engineers to optimize metal forming techniques, improve product durability, and reduce material waste in large-scale manufacturing.

Factors Affecting Ductility and Malleability in Alloys

Ductility and malleability in alloys are primarily influenced by atomic bonding, crystal structure, temperature, and impurity levels. Increased temperature enhances atomic mobility, boosting both ductility and malleability, while the presence of impurities or alloying elements can disrupt dislocation movement, reducing these properties. Grain size refinement and heat treatment processes also play critical roles in optimizing the balance between ductility and malleability for specific alloy applications.

Enhancing Material Performance: Engineering Approaches

Engineering approaches to enhance ductility and malleability focus on microstructure control through techniques such as alloying, heat treatment, and thermomechanical processing. Grain size refinement and phase distribution optimization improve material performance by enabling higher plastic deformation without failure. Tailored processing parameters facilitate desired balance between ductility and malleability, optimizing materials for specific mechanical requirements in applications like aerospace and automotive industries.

Plastic deformation

Ductility measures a material's ability to undergo plastic deformation under tensile stress, while malleability describes its capacity for plastic deformation under compressive stress.

Tensile strength

Ductility measures a material's ability to undergo tensile deformation without breaking, directly correlating with tensile strength, while malleability refers to a material's capacity to deform under compressive stress without cracking.

Yield point

Ductility measures a material's ability to undergo plastic deformation before fracture, indicated by a clear yield point, while malleability refers to the capacity to deform under compressive stress without a distinct yield point.

Crystal lattice slip

Ductility refers to a material's ability to undergo significant plastic deformation through crystal lattice slip without fracturing, while malleability describes the ease with which a material's crystal lattice layers can slide past each other under compressive stress to form thin sheets.

Grain boundary mobility

Grain boundary mobility significantly influences ductility by enabling plastic deformation through dislocation movement, while malleability depends more on atomic plane slippage within grains, impacting material shape change without fracturing.

Work hardening

Ductility refers to a metal's ability to undergo significant plastic deformation before rupture, often decreased by work hardening, while malleability describes a metal's capacity to deform under compressive stress and generally exhibits less sensitivity to work hardening effects.

Brittleness

Brittleness describes a material's tendency to fracture under stress without significant deformation, contrasting with ductility and malleability which allow materials to stretch or shape without breaking.

Elongation-to-failure

Elongation-to-failure measures ductility by quantifying how much a material stretches before breaking, whereas malleability refers to a material's ability to deform under compressive stress without fracturing.

Forging temperature

Ductility increases at higher forging temperatures, allowing metals to stretch without breaking, while malleability improves as forging temperature rises, enabling metals to deform under compressive forces without cracking.

Cold rolling

Cold rolling enhances ductility by allowing metals to undergo significant plastic deformation without fracture, whereas malleability primarily refers to the metal's ability to be shaped under compressive forces like hammering.

Ductility vs Malleability Infographic

njnir.com

njnir.com