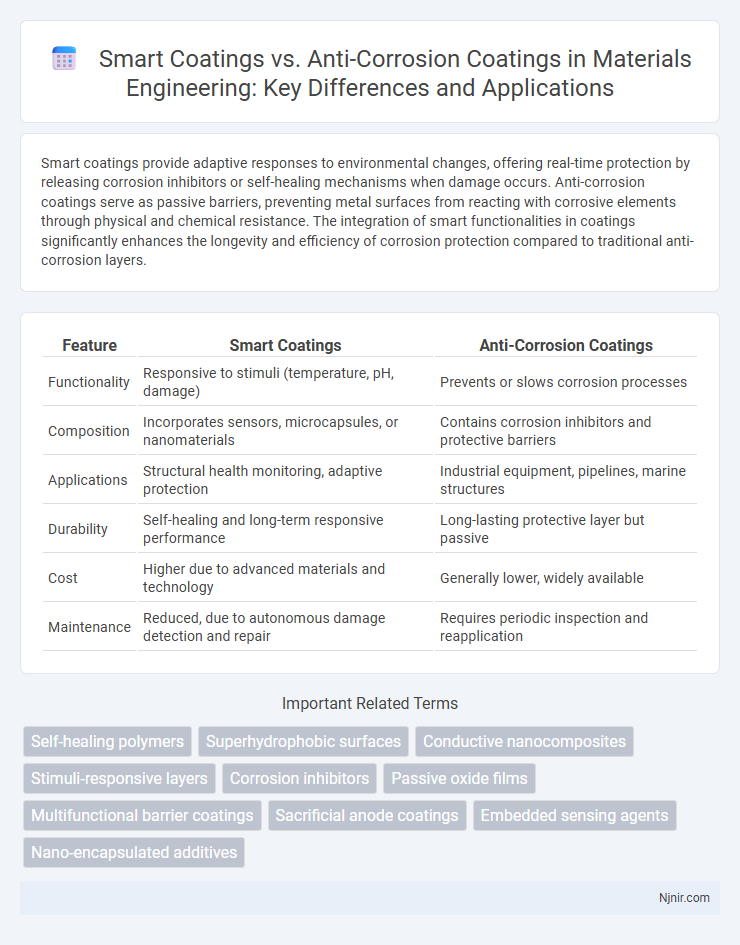

Smart coatings provide adaptive responses to environmental changes, offering real-time protection by releasing corrosion inhibitors or self-healing mechanisms when damage occurs. Anti-corrosion coatings serve as passive barriers, preventing metal surfaces from reacting with corrosive elements through physical and chemical resistance. The integration of smart functionalities in coatings significantly enhances the longevity and efficiency of corrosion protection compared to traditional anti-corrosion layers.

Table of Comparison

| Feature | Smart Coatings | Anti-Corrosion Coatings |

|---|---|---|

| Functionality | Responsive to stimuli (temperature, pH, damage) | Prevents or slows corrosion processes |

| Composition | Incorporates sensors, microcapsules, or nanomaterials | Contains corrosion inhibitors and protective barriers |

| Applications | Structural health monitoring, adaptive protection | Industrial equipment, pipelines, marine structures |

| Durability | Self-healing and long-term responsive performance | Long-lasting protective layer but passive |

| Cost | Higher due to advanced materials and technology | Generally lower, widely available |

| Maintenance | Reduced, due to autonomous damage detection and repair | Requires periodic inspection and reapplication |

Introduction to Smart Coatings and Anti-Corrosion Coatings

Smart coatings incorporate advanced functionalities such as self-healing, corrosion sensing, and responsive release of inhibitors to extend material lifespan beyond traditional barriers. Anti-corrosion coatings primarily serve as protective layers that prevent metal degradation by creating a physical barrier against moisture, oxygen, and chemicals. Innovations in smart coatings integrate multiple protective mechanisms, enhancing performance over conventional anti-corrosion coatings in harsh environments.

Defining Smart Coatings in Modern Materials Engineering

Smart coatings in modern materials engineering are advanced functional surfaces engineered to respond adaptively to environmental stimuli such as temperature, pH, or mechanical stress, enhancing protection and durability. These coatings incorporate self-healing, self-cleaning, or corrosion-sensing technologies that surpass traditional anti-corrosion coatings by actively mitigating damage rather than merely providing a passive barrier. By integrating nanotechnology, microencapsulation, and responsive polymers, smart coatings offer dynamic and prolonged corrosion resistance in various industrial applications.

Mechanisms of Corrosion Protection in Anti-Corrosion Coatings

Anti-corrosion coatings protect metal surfaces primarily through barrier mechanisms that prevent moisture, oxygen, and corrosive ions from reaching the substrate, often incorporating pigments like zinc phosphate for sacrificial protection. Smart coatings enhance these traditional methods by integrating responsive materials that detect early corrosion signs and release inhibitors or self-healing agents to arrest damage dynamically. The combination of passive barrier effects and active responses in smart coatings offers superior durability and prolonged metal lifespan compared to conventional anti-corrosion solutions.

Comparative Analysis: Functionalities and Properties

Smart coatings incorporate responsive materials that adapt to environmental changes, providing self-healing, corrosion sensing, and anti-corrosion capabilities, while traditional anti-corrosion coatings primarily offer passive barrier protection against moisture and chemical exposure. Functionalities of smart coatings include real-time damage detection and autonomous repair, enhancing durability and reducing maintenance costs compared to conventional coatings which lack such dynamic properties. Properties of smart coatings often feature nanostructured materials and stimuli-responsive polymers, enabling multifunctional performance beyond the static protective layer of typical anti-corrosion coatings.

Material Selection and Formulation Strategies

Smart coatings utilize advanced materials such as microcapsules, stimuli-responsive polymers, and nanomaterials to provide self-healing and adaptive corrosion protection, enhancing longevity through dynamic responses to environmental changes. Anti-corrosion coatings primarily rely on barrier materials like epoxy resins, zinc-rich primers, and polyurethane formulations designed to prevent metal oxidation by creating impermeable layers. Material selection for smart coatings emphasizes multifunctionality and environmental responsiveness, whereas traditional anti-corrosion coatings focus on chemical resistance and mechanical durability to inhibit corrosion processes.

Advancements in Self-Healing and Sensing Technologies

Smart coatings incorporate advanced self-healing materials that autonomously repair microcracks, enhancing durability beyond traditional anti-corrosion coatings that mainly provide passive barrier protection. Cutting-edge sensing technologies embedded in smart coatings monitor environmental factors such as humidity, temperature, and chemical exposure in real-time, enabling predictive maintenance and early detection of corrosion. These innovations significantly extend the lifespan of metal structures and reduce maintenance costs by combining active protection with intelligent monitoring capabilities.

Application Areas: Industrial and Commercial Use Cases

Smart coatings find extensive application in industrial sectors such as aerospace, automotive, and electronics, where their self-healing and responsive properties protect against environmental damage and enhance material longevity. Anti-corrosion coatings are primarily utilized in heavy industries, including oil and gas pipelines, marine vessels, and infrastructure projects, to prevent rust and degradation caused by moisture and chemical exposure. Both coatings improve maintenance efficiency and asset durability, but smart coatings offer advanced functionalities like corrosion sensing and real-time protection in commercial and industrial environments.

Performance Evaluation: Testing Standards and Metrics

Smart coatings demonstrate enhanced performance evaluation through dynamic response testing, self-healing efficiency metrics, and real-time corrosion rate monitoring, distinguishing them from traditional anti-corrosion coatings that primarily rely on standardized salt spray and adhesion tests such as ASTM B117 and ISO 4628. Performance metrics for smart coatings include electrochemical impedance spectroscopy (EIS) for barrier properties and localized pH measurements to assess active corrosion inhibition, providing a comprehensive understanding of protective functionality under varying environmental stimuli. Anti-corrosion coatings often focus on durability and resistance metrics like adhesion strength and corrosion undercutting, while smart coatings integrate multifunctional performance assessments to evaluate their adaptive protective capabilities.

Environmental Impact and Sustainability Considerations

Smart coatings utilize advanced materials that enable self-healing and corrosion detection, significantly reducing the need for frequent recoating and lowering environmental waste. Anti-corrosion coatings primarily act as physical barriers to prevent rust, often containing heavy metals or volatile organic compounds (VOCs) that can harm ecosystems during application and degradation. Emphasizing sustainability, smart coatings promote longer infrastructure life and minimize chemical pollutants, aligning with eco-friendly industrial practices and regulatory demands for reduced environmental impact.

Future Trends and Research Directions in Coating Technologies

Future trends in smart coatings emphasize multifunctionality, integrating self-healing, corrosion sensing, and controlled release of inhibitors to enhance longevity and environmental sustainability. Advanced nanomaterials and stimuli-responsive polymers remain at the forefront of research, enabling coatings to adapt dynamically to environmental changes and mechanical damage. Continued exploration of green chemistry approaches aims to develop eco-friendly anti-corrosion solutions with superior performance, minimizing toxic byproducts and extending infrastructure lifespan.

Self-healing polymers

Self-healing polymers in smart coatings autonomously repair micro-cracks to enhance corrosion resistance, offering superior durability compared to traditional anti-corrosion coatings.

Superhydrophobic surfaces

Superhydrophobic surfaces in smart coatings provide enhanced self-cleaning and water-repellent properties, significantly outperformChuan Tong anti-corrosion coatings in preventing moisture-induced corrosion.

Conductive nanocomposites

Conductive nanocomposite-based smart coatings offer enhanced multifunctional anti-corrosion protection by enabling real-time damage sensing and self-healing properties beyond traditional passive anti-corrosion coatings.

Stimuli-responsive layers

Stimuli-responsive smart coatings adapt their protective properties in response to environmental changes, providing dynamic corrosion resistance superior to traditional static anti-corrosion coatings.

Corrosion inhibitors

Smart coatings incorporate advanced corrosion inhibitors that respond to environmental changes, providing enhanced and self-healing protection compared to traditional anti-corrosion coatings.

Passive oxide films

Passive oxide films in smart coatings provide self-healing properties by dynamically repairing damage, while traditional anti-corrosion coatings primarily offer static barrier protection against environmental factors.

Multifunctional barrier coatings

Multifunctional barrier coatings integrate smart responsive properties with traditional anti-corrosion features to provide enhanced protection and self-healing capabilities for metal surfaces.

Sacrificial anode coatings

Sacrificial anode coatings, a type of smart coating, provide enhanced anti-corrosion protection by actively corroding to protect the underlying metal substrate.

Embedded sensing agents

Smart coatings embedded with sensing agents detect and signal early corrosion threats, enhancing proactive maintenance compared to traditional anti-corrosion coatings that only provide passive protection.

Nano-encapsulated additives

Nano-encapsulated additives in smart coatings provide targeted, controlled release of anti-corrosion agents, enhancing durability and self-healing properties compared to traditional anti-corrosion coatings.

Smart coatings vs Anti-corrosion coatings Infographic

njnir.com

njnir.com