Electron beam melting (EBM) utilizes a high-energy electron beam in a vacuum to melt metal powders, offering superior thermal efficiency and reduced residual stresses compared to selective laser melting (SLM). EBM allows for faster build rates and better control over microstructure due to its high temperatures and vacuum environment, making it ideal for high-performance aerospace and medical implants. In contrast, SLM provides finer resolution and surface finish suitable for complex geometries but often requires post-processing to alleviate internal stresses.

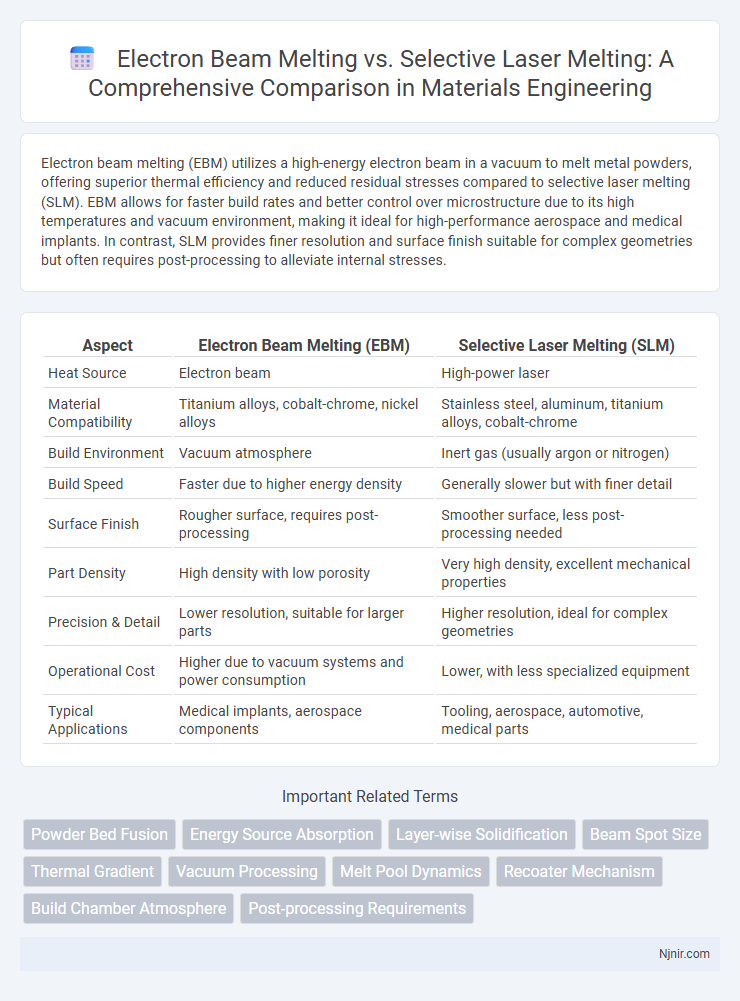

Table of Comparison

| Aspect | Electron Beam Melting (EBM) | Selective Laser Melting (SLM) |

|---|---|---|

| Heat Source | Electron beam | High-power laser |

| Material Compatibility | Titanium alloys, cobalt-chrome, nickel alloys | Stainless steel, aluminum, titanium alloys, cobalt-chrome |

| Build Environment | Vacuum atmosphere | Inert gas (usually argon or nitrogen) |

| Build Speed | Faster due to higher energy density | Generally slower but with finer detail |

| Surface Finish | Rougher surface, requires post-processing | Smoother surface, less post-processing needed |

| Part Density | High density with low porosity | Very high density, excellent mechanical properties |

| Precision & Detail | Lower resolution, suitable for larger parts | Higher resolution, ideal for complex geometries |

| Operational Cost | Higher due to vacuum systems and power consumption | Lower, with less specialized equipment |

| Typical Applications | Medical implants, aerospace components | Tooling, aerospace, automotive, medical parts |

Introduction to Electron Beam Melting (EBM) and Selective Laser Melting (SLM)

Electron Beam Melting (EBM) uses a high-energy electron beam to selectively melt metal powder layer by layer in a vacuum environment, enabling rapid cooling and reduced residual stresses, often applied in aerospace and medical implants. Selective Laser Melting (SLM) employs a high-power laser to fuse metal powders under an inert gas atmosphere, offering precise control over microstructure and dimensional accuracy, commonly utilized in complex geometries and prototyping. Both additive manufacturing techniques enable complex part production with tailored mechanical properties but differ in energy sources, process environments, and material compatibility.

Historical Development and Adoption in Industry

Electron Beam Melting (EBM) emerged in the 1990s as an innovative additive manufacturing technology utilizing electron beams to fuse metal powder, initially adopted by aerospace and medical industries due to its ability to produce high-density, complex titanium parts. Selective Laser Melting (SLM), developed slightly later in the early 2000s, gained rapid traction across automotive, aerospace, and tooling sectors for its versatility in processing a broader range of metals with high precision and surface finish. Both technologies have evolved with advancements in power sources and process control, accelerating their integration into industrial production lines for customized, lightweight, and high-performance components.

Fundamental Working Principles: EBM vs SLM

Electron Beam Melting (EBM) utilizes a high-energy electron beam under vacuum conditions to selectively melt metal powder layer by layer, relying on electromagnetic lenses for precise beam control. Selective Laser Melting (SLM) employs a high-power laser beam in a controlled inert gas atmosphere to fuse metal powder, using galvanometer scanners to direct the laser path with rapid accuracy. Both processes achieve metal part fabrication through additive manufacturing but differ significantly in energy source, atmosphere, and thermal management, impacting material properties and process efficiency.

Materials Compatibility for EBM and SLM Processes

Electron Beam Melting (EBM) is highly compatible with reactive and high-temperature metals such as titanium alloys and cobalt-chrome due to its high-vacuum environment, which reduces oxidation during processing. Selective Laser Melting (SLM) offers greater versatility with a wider range of materials, including stainless steels, aluminum alloys, and tool steels, thanks to its inert gas atmosphere that controls oxidation while allowing finer resolution. Material compatibility in EBM favors dense, fully melted parts with coarse microstructures, whereas SLM supports finer microstructures and complex geometries but may require more rigorous post-processing for stress relief.

Process Environment: Vacuum vs Inert Gas Protection

Electron beam melting operates in a high-vacuum environment, eliminating oxidation and contamination risks, thereby enhancing material purity and mechanical properties. Selective laser melting uses an inert gas atmosphere, typically argon or nitrogen, to prevent oxidation while allowing for faster cooling rates and more flexible machine configurations. The vacuum in electron beam melting restricts material choices due to vapor pressure, whereas selective laser melting's gas environment enables a broader range of alloys and complex geometries.

Build Quality: Surface Finish and Dimensional Accuracy

Electron Beam Melting (EBM) typically produces parts with a rougher surface finish compared to Selective Laser Melting (SLM) due to its higher build temperatures and powder coarseness. SLM offers superior dimensional accuracy and finer surface details, making it more suitable for applications requiring tight tolerances and smooth finishes. Differences in energy source and powder handling between EBM and SLM significantly influence the final part quality, impacting post-processing requirements and overall manufacturing efficiency.

Mechanical Properties of Fabricated Parts

Electron Beam Melting (EBM) typically produces parts with higher ductility and better thermal conductivity due to its elevated build temperatures and vacuum environment, resulting in reduced residual stresses compared to Selective Laser Melting (SLM). SLM often yields parts with finer microstructures and higher tensile strength but may exhibit increased anisotropy and residual stresses due to rapid cooling rates. Both methods achieve comparable hardness levels, but EBM parts generally demonstrate improved fatigue resistance and fracture toughness in materials like titanium alloys.

Process Limitations and Design Considerations

Electron Beam Melting (EBM) faces process limitations such as a vacuum environment requirement and slower build rates compared to Selective Laser Melting (SLM), which allows for processing in an inert gas atmosphere and generally achieves finer feature resolution. EBM typically results in rougher surface finishes and is better suited for materials like titanium alloys, whereas SLM offers greater design flexibility with finer detail and more complex geometries due to its laser's precision. Design considerations for EBM must account for part distortion from thermal gradients and support structures, while SLM requires careful management of residual stresses and supports to prevent warping and maintain dimensional accuracy.

Cost Analysis and Production Throughput Comparison

Electron Beam Melting (EBM) generally incurs higher initial equipment costs due to its vacuum environment and electron gun technology but offers lower energy consumption per build compared to Selective Laser Melting (SLM). In production throughput, EBM achieves faster build rates for large, less detailed parts due to higher layer thickness and scan speeds, while SLM excels in producing intricate geometries with finer resolution but slower build times, impacting cost-efficiency for complex components. Cost analysis reveals that SLM's higher operational expenses from laser maintenance and inert gas usage can outweigh its precision advantages in mass production, whereas EBM's lower material wastage and faster bulk builds optimize costs in high-volume manufacturing.

Future Trends and Innovations in Additive Manufacturing

Electron Beam Melting (EBM) and Selective Laser Melting (SLM) are evolving with advancements such as improved energy source control and hybrid manufacturing integrations that enhance precision and material properties. Future trends emphasize the development of real-time monitoring systems and AI-driven process optimization to reduce defects and increase reproducibility in complex metal parts. Innovations in multi-material printing and surface finishing techniques aim to expand the applications of both EBM and SLM in aerospace, medical implants, and automotive industries.

Powder Bed Fusion

Electron Beam Melting (EBM) uses a high-energy electron beam under vacuum for Powder Bed Fusion, providing faster build rates and superior thermal management, while Selective Laser Melting (SLM) employs a laser in an inert gas atmosphere, offering finer resolution and better surface finish for complex geometries.

Energy Source Absorption

Electron beam melting achieves higher energy absorption efficiency due to its vacuum environment and deeper penetration, whereas selective laser melting experiences more variable absorption influenced by surface oxidation and powder reflectivity.

Layer-wise Solidification

Electron beam melting achieves layer-wise solidification through high-energy electron beams enabling faster melt pool cooling rates and reduced residual stresses compared to selective laser melting's photon-based laser process.

Beam Spot Size

Electron beam melting typically achieves a smaller beam spot size of around 0.1-0.3 mm compared to selective laser melting's laser spot size of approximately 0.1-0.5 mm, enabling finer resolution and detail in printed parts.

Thermal Gradient

Electron beam melting generates higher thermal gradients than selective laser melting, resulting in faster solidification rates and differing microstructural characteristics.

Vacuum Processing

Electron beam melting operates within a high-vacuum environment that minimizes oxidation and contamination, enabling superior material density and mechanical properties compared to selective laser melting, which typically occurs in an inert gas atmosphere.

Melt Pool Dynamics

Electron beam melting generates a deeper and more stable melt pool with higher energy density and vacuum conditions, while selective laser melting produces a shallower melt pool with faster solidification rates due to localized laser heating in atmospheric environments.

Recoater Mechanism

The electron beam melting (EBM) recoater mechanism utilizes a robust, vacuum-compatible blade to uniformly spread metal powder layers, offering higher precision and reduced contamination compared to the selective laser melting (SLM) recoater system, which employs a faster but more delicate recoating blade suited for atmospheric conditions.

Build Chamber Atmosphere

Electron beam melting operates in a high-vacuum build chamber atmosphere to prevent electron scattering, while selective laser melting uses an inert gas-filled chamber to minimize oxidation and contamination.

Post-processing Requirements

Electron beam melting requires less intensive post-processing due to reduced residual stresses and minimal oxidation, whereas selective laser melting often demands extensive heat treatment and surface finishing to address higher residual stresses and surface roughness.

electron beam melting vs selective laser melting Infographic

njnir.com

njnir.com