Metallic glass exhibits an amorphous atomic structure that significantly enhances its strength and elasticity compared to traditional crystalline metals. These non-crystalline metals lack grain boundaries, resulting in superior corrosion resistance and improved wear properties. However, metallic glasses typically have lower ductility than their crystalline counterparts, limiting their use in applications requiring extensive deformation.

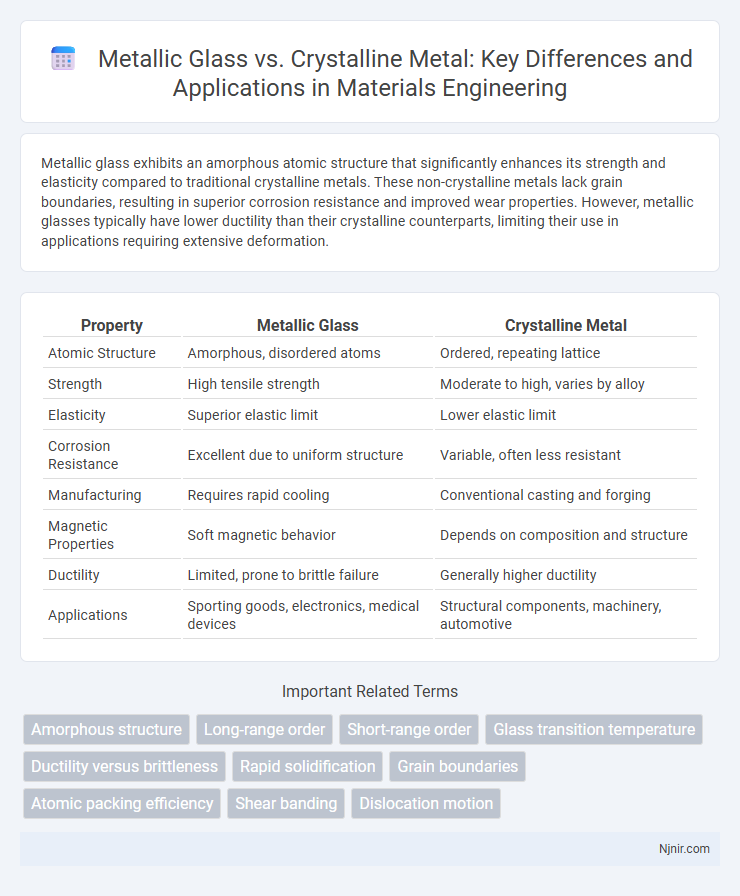

Table of Comparison

| Property | Metallic Glass | Crystalline Metal |

|---|---|---|

| Atomic Structure | Amorphous, disordered atoms | Ordered, repeating lattice |

| Strength | High tensile strength | Moderate to high, varies by alloy |

| Elasticity | Superior elastic limit | Lower elastic limit |

| Corrosion Resistance | Excellent due to uniform structure | Variable, often less resistant |

| Manufacturing | Requires rapid cooling | Conventional casting and forging |

| Magnetic Properties | Soft magnetic behavior | Depends on composition and structure |

| Ductility | Limited, prone to brittle failure | Generally higher ductility |

| Applications | Sporting goods, electronics, medical devices | Structural components, machinery, automotive |

Introduction to Metallic Glass and Crystalline Metal

Metallic glass, also known as amorphous metal, lacks the long-range ordered atomic structure found in crystalline metals, resulting in unique mechanical and magnetic properties. Crystalline metals exhibit a highly ordered lattice arrangement that contributes to their distinct stiffness and ductility. The absence of grain boundaries in metallic glass enhances strength and corrosion resistance compared to their crystalline counterparts.

Atomic Structure: Amorphous vs. Crystalline

Metallic glass features an amorphous atomic structure where atoms are arranged randomly without a long-range order, contrasting with crystalline metals that possess a highly ordered, repeating atomic lattice. This lack of crystallinity in metallic glass results in unique mechanical properties like high strength and elasticity. Crystalline metals, on the other hand, tend to exhibit grain boundaries and dislocations that influence their plasticity and ductility.

Mechanical Properties Comparison

Metallic glass exhibits higher strength and hardness than crystalline metals due to its amorphous atomic structure, which eliminates dislocation movement and grain boundaries. Crystalline metals typically have better ductility and toughness, allowing them to deform plastically before fracture, whereas metallic glass tends to be more brittle under tensile stress. The superior elastic limit of metallic glass, often reaching 2%, surpasses that of crystalline metals, enabling enhanced elastic energy storage and resilience.

Thermal Stability and Behavior

Metallic glass exhibits superior thermal stability compared to crystalline metals due to its amorphous atomic structure, which minimizes grain boundary weaknesses and reduces atomic diffusion rates. This unique disordered arrangement enables metallic glasses to maintain mechanical properties at elevated temperatures without crystallization up to their glass transition temperature (Tg). In contrast, crystalline metals experience phase transformations and grain growth that degrade their mechanical performance and thermal stability under similar conditions.

Corrosion Resistance: Metallic Glass vs. Crystalline Metal

Metallic glass exhibits superior corrosion resistance compared to crystalline metals due to its non-crystalline atomic structure, which eliminates grain boundaries and defects that typically act as initiation sites for corrosion. The homogeneous and tightly packed atomic arrangement in metallic glass enhances its chemical stability and reduces susceptibility to localized corrosion such as pitting and crevice corrosion. In contrast, crystalline metals contain grain boundaries and dislocations that provide pathways for corrosive agents, resulting in higher corrosion rates and compromised durability.

Electrical and Magnetic Properties

Metallic glass exhibits higher electrical resistivity compared to crystalline metals due to its disordered atomic structure, which disrupts electron flow and reduces conductivity. Its lack of grain boundaries and defects found in crystalline metals also leads to lower magnetic coercivity and enhanced soft magnetic properties, making it ideal for transformer cores and magnetic shielding. In contrast, crystalline metals typically show lower resistivity and higher magnetic hysteresis because of their ordered lattice and domain wall movements.

Fabrication Techniques and Processing Methods

Metallic glass is primarily fabricated using rapid cooling techniques such as melt spinning or liquid quenching, which prevent atomic ordering and promote an amorphous structure. Crystalline metals are typically processed through conventional methods like casting, forging, and annealing to achieve controlled grain growth and phase distribution. Advanced methods like physical vapor deposition (PVD) and additive manufacturing are also employed to tailor microstructures in both materials for specific applications.

Applications in Industry and Technology

Metallic glass exhibits superior strength and elasticity compared to crystalline metals, making it ideal for precision components in aerospace, electronics, and medical devices. Its amorphous structure enhances corrosion resistance and wear properties, driving innovations in sports equipment, transformer cores, and microelectromechanical systems (MEMS). Crystalline metals, favored for their ductility and ease of manufacturing, remain dominant in large-scale structural applications, automotive parts, and heavy machinery.

Limitations and Challenges

Metallic glass exhibits superior strength and corrosion resistance compared to crystalline metals but faces significant limitations such as brittleness and size constraints during fabrication. The absence of a crystalline structure causes challenges in controlling mechanical properties, leading to unpredictable fracture behavior under stress. Manufacturing techniques are restricted by cooling rates required to maintain amorphous structures, limiting the production of bulk metallic glass components for widespread industrial applications.

Future Prospects and Research Directions

Metallic glasses exhibit exceptional strength, corrosion resistance, and elastic limits compared to crystalline metals, positioning them as promising candidates for advanced structural and biomedical applications. Future research focuses on enhancing their ductility, understanding atomic-scale deformation mechanisms, and developing scalable manufacturing processes to enable widespread industrial use. Advances in alloy design and additive manufacturing techniques are expected to accelerate the integration of metallic glasses in aerospace, electronics, and energy storage technologies.

Amorphous structure

Metallic glass features an amorphous atomic structure lacking the long-range order present in crystalline metals, resulting in unique properties such as high strength, corrosion resistance, and enhanced elasticity.

Long-range order

Metallic glass lacks long-range atomic order found in crystalline metals, resulting in unique mechanical and magnetic properties.

Short-range order

Metallic glass exhibits disordered short-range atomic arrangements, unlike crystalline metals which have well-defined periodic short-range order.

Glass transition temperature

Metallic glasses exhibit a distinct glass transition temperature absent in crystalline metals, indicating a transition from a hard and brittle state to a more ductile and moldable state.

Ductility versus brittleness

Metallic glass exhibits higher brittleness with limited ductility due to its amorphous atomic structure, whereas crystalline metals demonstrate greater ductility and reduced brittleness owing to their organized lattice structures that allow dislocation movement.

Rapid solidification

Rapid solidification enhances metallic glass formation by bypassing crystalline nucleation, resulting in an amorphous structure with superior strength and corrosion resistance compared to traditionally solidified crystalline metals.

Grain boundaries

Metallic glass lacks grain boundaries found in crystalline metals, resulting in higher strength and improved corrosion resistance.

Atomic packing efficiency

Metallic glass exhibits higher atomic packing efficiency than crystalline metals due to its disordered atomic structure, resulting in superior strength and enhanced corrosion resistance.

Shear banding

Metallic glass exhibits localized shear banding due to its amorphous structure, resulting in limited plastic deformation, whereas crystalline metals display more uniform deformation with dislocation movements mitigating shear band propagation.

Dislocation motion

Metallic glass exhibits superior strength and hardness compared to crystalline metal due to the absence of dislocation motion in its amorphous atomic structure.

metallic glass vs crystalline metal Infographic

njnir.com

njnir.com