Electrospun nanofibers exhibit superior surface area-to-volume ratios and enhanced porosity compared to melt-blown fibers, enabling improved filtration efficiency and mechanical strength. The controlled fiber diameter and morphology in electrospinning allow for precise tuning of material properties, making these nanofibers ideal for advanced applications such as tissue engineering and sensor development. Melt-blown fibers, while cost-effective and suitable for mass production, often lack the fine structural control and functional versatility inherent in electrospun nanofibers.

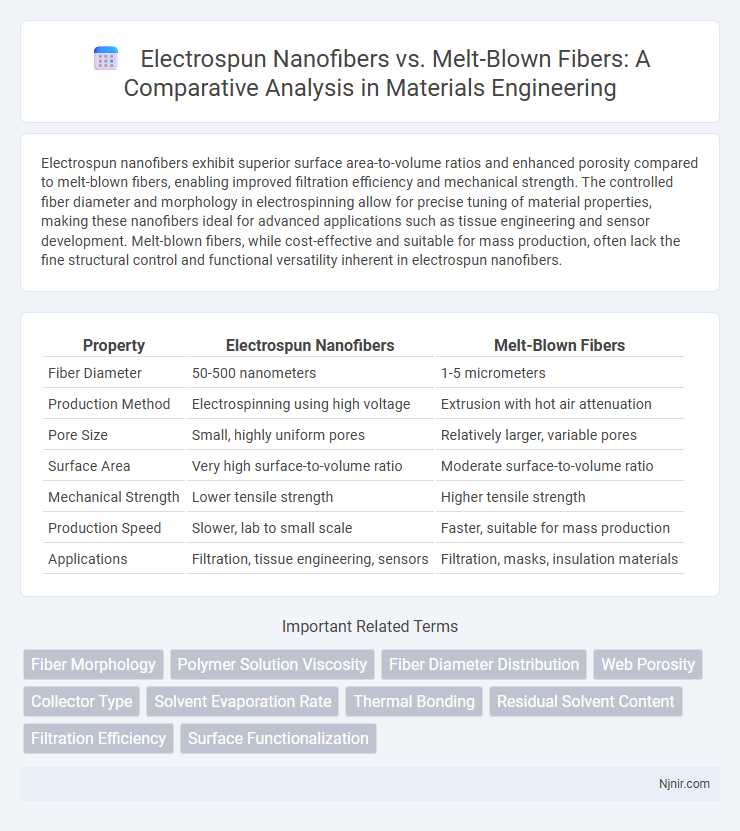

Table of Comparison

| Property | Electrospun Nanofibers | Melt-Blown Fibers |

|---|---|---|

| Fiber Diameter | 50-500 nanometers | 1-5 micrometers |

| Production Method | Electrospinning using high voltage | Extrusion with hot air attenuation |

| Pore Size | Small, highly uniform pores | Relatively larger, variable pores |

| Surface Area | Very high surface-to-volume ratio | Moderate surface-to-volume ratio |

| Mechanical Strength | Lower tensile strength | Higher tensile strength |

| Production Speed | Slower, lab to small scale | Faster, suitable for mass production |

| Applications | Filtration, tissue engineering, sensors | Filtration, masks, insulation materials |

Introduction to Fiber Production Techniques

Electrospun nanofibers are produced by applying a high-voltage electric field to a polymer solution or melt, creating fibers with diameters in the nanometer range, offering high surface area and porosity. Melt-blown fibers are generated by extruding molten polymer through fine nozzles, followed by high-velocity hot air to form microfibers commonly used in filtration and insulation. Both techniques differ significantly in fiber morphology, production scale, and application potential, with electrospinning enabling finer fibers for advanced filtration and biomedical uses, while melt-blowing supports mass production for industrial applications.

Overview of Electrospinning and Melt-Blown Processes

Electrospinning utilizes a high-voltage electric field to draw charged polymer solutions or melts into fine nanofibers, producing fibers with diameters typically ranging from tens to hundreds of nanometers. Melt-blown technology involves extruding molten polymers through micro-sized nozzles, followed by high-velocity hot air to form continuous fibers with diameters usually in the micron range. The electrospinning process allows precise control over fiber morphology and porosity, making it ideal for applications requiring ultra-fine structures, whereas melt-blown processes excel in high-throughput production of nonwoven mats used in filtration and insulation.

Comparison of Fiber Morphology and Structure

Electrospun nanofibers exhibit a highly uniform diameter distribution ranging from tens to hundreds of nanometers, resulting in a large surface area-to-volume ratio ideal for filtration and biomedical applications. Melt-blown fibers typically possess diameters in the micrometer range with less uniformity and a more porous, random fiber arrangement, providing effective bulk mechanical strength and breathability. The distinct morphologies stem from electrospinning's voltage-induced jet thinning versus melt-blowing's high-velocity air attenuation, influencing properties such as fiber diameter, porosity, and mechanical stability.

Material Selection for Electrospinning vs Melt-Blowing

Material selection for electrospinning emphasizes polymers with high molecular weight and solubility in volatile solvents, such as polyvinyl alcohol (PVA), polycaprolactone (PCL), and polyethylene oxide (PEO), to achieve uniform nanofiber formation. Melt-blowing favors thermoplastic polymers with appropriate melt viscosity and thermal stability like polypropylene (PP) and polyethylene (PE) to enable fiber extrusion without solvent use. Electrospinning allows for more diverse polymer and composite incorporation due to solution-phase processing, whereas melt-blowing is limited to melt-processable polymers suitable for high-throughput production.

Mechanical Properties: Strength and Flexibility

Electrospun nanofibers exhibit superior mechanical strength and enhanced flexibility due to their high surface area-to-volume ratio and uniform fiber diameter, which enable better stress distribution under load. Melt-blown fibers, while offering reasonable strength, often display lower flexibility and less uniform mechanical performance because of their larger fiber diameters and less controlled morphology. The nanoscale architecture of electrospun fibers allows for improved tensile strength and elongation at break compared to the microscale fibers produced by melt-blowing techniques.

Functionalization and Surface Modification Capabilities

Electrospun nanofibers exhibit superior functionalization and surface modification capabilities due to their high surface area-to-volume ratio and tunable fiber diameter, enabling effective incorporation of nanoparticles, bioactive molecules, and chemical groups. Melt-blown fibers, while produced at higher throughput, offer more limited surface modification options primarily through post-processing treatments such as coating or plasma activation. The intrinsic nanoscale architecture of electrospun fibers facilitates enhanced interaction with functional agents, resulting in advanced performance for filtration, biomedical scaffolds, and sensor applications.

Applications in Filtration and Protective Textiles

Electrospun nanofibers exhibit superior filtration efficiency and breathability compared to melt-blown fibers due to their smaller fiber diameters and higher surface area, making them ideal for advanced air and liquid filtration systems. Melt-blown fibers, widely used in disposable masks and protective clothing, offer cost-effective production and adequate barrier properties against particulates and pathogens. The integration of electrospun nanofibers with melt-blown substrates enhances filtration performance in protective textiles, providing high particle capture rates while maintaining comfort and durability.

Scalability and Industrial Production Considerations

Electrospun nanofibers offer superior control over fiber diameter and morphology, making them ideal for specialized applications but are limited by slower production rates and higher costs. Melt-blown fibers, widely used in mass production, enable high-throughput manufacturing with lower operational expenses, supporting large-scale industrial demands. Scalability of electrospinning remains a challenge due to complex equipment and sensitivity to parameters, whereas melt-blown technology benefits from well-established, continuous processes suitable for diverse markets.

Environmental Impact and Sustainability

Electrospun nanofibers offer enhanced environmental benefits due to their energy-efficient production process and ability to use biodegradable polymers, reducing landfill waste compared to melt-blown fibers, which often involve higher energy consumption and reliance on non-renewable petrochemical materials. The fine fiber diameter and high surface area of electrospun nanofibers enable superior filtration efficiencies, leading to longer product life and decreased material replacement frequency, further supporting sustainability goals. Melt-blown fibers, while widely used in industrial applications, typically generate more waste and have limited recyclability, presenting significant challenges in minimizing environmental footprints.

Future Trends and Research Directions

Electrospun nanofibers offer superior surface area and tunable porosity compared to melt-blown fibers, driving research toward advanced filtration, biomedical applications, and energy storage. Future trends emphasize scalable production techniques, integration with functional nanoparticles, and environmentally sustainable materials to enhance performance and reduce ecological impact. Ongoing studies explore hybrid fiber systems combining electrospinning and melt-blown methods to optimize mechanical strength and specificity for next-generation smart textiles and wearable devices.

Fiber Morphology

Electrospun nanofibers exhibit uniform diameters ranging from tens to hundreds of nanometers with smooth, continuous morphology, while melt-blown fibers typically show larger, micrometer-scale diameters with less uniformity and a rougher surface texture.

Polymer Solution Viscosity

Electrospun nanofibers require polymer solution viscosities typically ranging from 100 to 1,000 cP to achieve uniform fiber formation, whereas melt-blown fibers rely on polymer melt viscosities above 1,000 Poise to ensure proper fiber extrusion and attenuation.

Fiber Diameter Distribution

Electrospun nanofibers exhibit a significantly narrower fiber diameter distribution, typically ranging from 50 to 500 nanometers, compared to melt-blown fibers which commonly have diameters between 1 to 10 micrometers with a broader size variability.

Web Porosity

Electrospun nanofibers exhibit significantly higher web porosity compared to melt-blown fibers, enabling enhanced filtration efficiency and breathability.

Collector Type

Electrospun nanofibers utilize various collector types such as stationary plates, rotating drums, or patterned electrodes to control fiber alignment and morphology, while melt-blown fibers primarily rely on a single-type stationary or moving belt collector to produce micro-scale nonwoven webs.

Solvent Evaporation Rate

Electrospun nanofibers exhibit a faster solvent evaporation rate compared to melt-blown fibers due to their ultrafine fiber diameter and high surface area-to-volume ratio, enhancing solvent diffusion and drying efficiency.

Thermal Bonding

Electrospun nanofibers exhibit superior thermal bonding capabilities compared to melt-blown fibers due to their higher surface area and uniform fiber diameter, enabling enhanced adhesion and mechanical strength in composite materials.

Residual Solvent Content

Electrospun nanofibers typically exhibit higher residual solvent content compared to melt-blown fibers due to the solvent-based fabrication process, impacting biocompatibility and material performance.

Filtration Efficiency

Electrospun nanofibers exhibit significantly higher filtration efficiency due to their smaller fiber diameter and greater surface area compared to melt-blown fibers, enabling superior capture of submicron particles.

Surface Functionalization

Electrospun nanofibers offer superior surface functionalization capabilities compared to melt-blown fibers due to their higher surface area-to-volume ratio and tunable fiber morphology.

Electrospun nanofibers vs Melt-blown fibers Infographic

njnir.com

njnir.com