Metamaterials exhibit unique electromagnetic properties not found in conventional materials due to their engineered microstructures, enabling novel applications such as negative refraction and cloaking devices. Unlike conventional materials whose properties are determined by chemical composition, metamaterials derive functionality from their physical structure at subwavelength scales. This structural control allows metamaterials to manipulate waves in ways that conventional materials cannot achieve, offering breakthroughs in optics, acoustics, and thermal management.

Table of Comparison

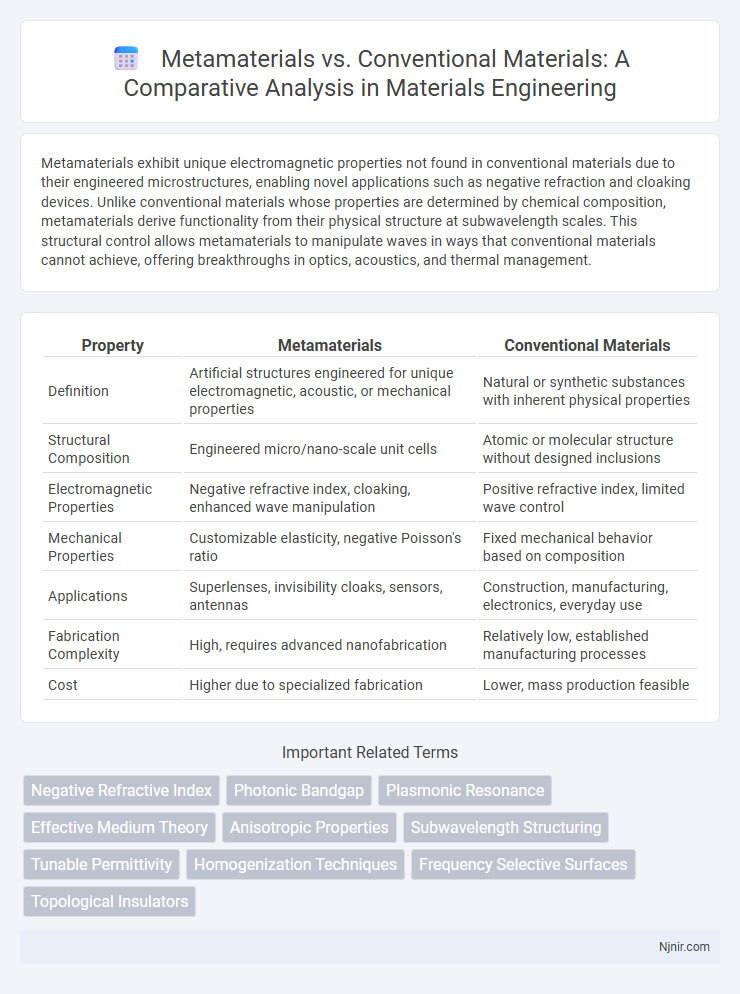

| Property | Metamaterials | Conventional Materials |

|---|---|---|

| Definition | Artificial structures engineered for unique electromagnetic, acoustic, or mechanical properties | Natural or synthetic substances with inherent physical properties |

| Structural Composition | Engineered micro/nano-scale unit cells | Atomic or molecular structure without designed inclusions |

| Electromagnetic Properties | Negative refractive index, cloaking, enhanced wave manipulation | Positive refractive index, limited wave control |

| Mechanical Properties | Customizable elasticity, negative Poisson's ratio | Fixed mechanical behavior based on composition |

| Applications | Superlenses, invisibility cloaks, sensors, antennas | Construction, manufacturing, electronics, everyday use |

| Fabrication Complexity | High, requires advanced nanofabrication | Relatively low, established manufacturing processes |

| Cost | Higher due to specialized fabrication | Lower, mass production feasible |

Introduction to Metamaterials and Conventional Materials

Metamaterials are artificially engineered structures designed to exhibit unique electromagnetic properties not found in conventional materials, enabling phenomena such as negative refraction and cloaking. Conventional materials, composed of natural atoms and molecules, possess fixed intrinsic properties dictated by their chemical composition and crystal structure. The key distinction lies in metamaterials' tailored architecture at the subwavelength scale, allowing control over wave propagation beyond the capabilities of traditional materials.

Fundamental Principles and Structure Comparison

Metamaterials consist of engineered structures with periodic subwavelength elements designed to manipulate electromagnetic waves through their geometry rather than chemical composition, contrasting with conventional materials whose properties arise from atomic composition and arrangement. The fundamental principles of metamaterials are based on effective medium theory, enabling negative refractive indices and tailored responses like cloaking, while conventional materials follow classical electromagnetic behavior dictated by Maxwell's equations in homogeneous media. Structurally, metamaterials feature distinctive unit cells such as split-ring resonators or wire arrays, enabling anisotropic and exotic properties, unlike the uniform, naturally occurring lattices of conventional materials.

Unique Properties of Metamaterials

Metamaterials exhibit unique properties such as negative refractive index and electromagnetic cloaking, which are unattainable with conventional materials composed of natural substances like metals and ceramics. These engineered composites manipulate waves--optic, acoustic, or electromagnetic--at a subwavelength scale, enabling unprecedented control over light and sound propagation. The capacity for tailored permittivity and permeability allows metamaterials to revolutionize applications in imaging, telecommunications, and stealth technology.

Mechanical Performance and Response Characteristics

Metamaterials exhibit unique mechanical performance and response characteristics due to their engineered microstructures, enabling properties such as negative Poisson's ratio, tunable stiffness, and enhanced energy absorption beyond those of conventional materials. Unlike traditional materials, which rely on their inherent chemistry for mechanical behavior, metamaterials derive functionality from their geometric design, allowing precise control over deformation patterns and dynamic responses under stress. These engineered responses result in applications spanning vibration damping, shock absorption, and adaptive load-bearing structures that outperform standard metals, polymers, and ceramics.

Applications in Electronics and Photonics

Metamaterials exhibit unique electromagnetic properties not found in conventional materials, enabling advanced applications in electronics and photonics such as superlenses, cloaking devices, and tunable antennas. Their engineered structures facilitate unprecedented control over light and radio waves, enhancing signal processing, sensing, and wireless communication technologies. Conventional materials, limited by natural electromagnetic responses, are often supplemented or replaced by metamaterials in cutting-edge devices requiring miniaturization and high performance.

Acoustic and Thermal Behavior Analysis

Metamaterials exhibit unique acoustic and thermal properties by manipulating wave propagation through engineered microstructures, enabling sound attenuation and heat flow control beyond the capabilities of conventional materials. Unlike traditional materials, which rely on intrinsic properties, metamaterials achieve negative refraction and anisotropic thermal conductivity, enhancing vibration isolation and thermal management in advanced applications. Analytical models and experimental studies demonstrate that metamaterials can be designed for targeted frequency ranges and temperature gradients, outperforming conventional materials in noise reduction and thermal insulation efficiency.

Fabrication Techniques and Scalability

Metamaterials rely on advanced fabrication techniques such as electron beam lithography, 3D printing, and nanoimprint lithography to achieve precise sub-wavelength structures, contrasting with the bulk manufacturing processes used for conventional materials. Scalability remains a significant challenge for metamaterials due to the complexity and high cost of nanofabrication methods, limiting large-scale production compared to the well-established, cost-effective fabrication of conventional materials. Efforts to develop roll-to-roll processing and self-assembly methods aim to enhance the scalability and economic viability of metamaterial production.

Cost Efficiency and Sustainability Considerations

Metamaterials offer enhanced cost efficiency by enabling lightweight, high-performance designs that reduce material consumption and manufacturing expenses compared to conventional materials. Their ability to achieve superior functionality with less raw material supports sustainability through lower resource extraction and energy use. Conventional materials often require more volume and energy-intensive processing, leading to higher environmental impact and less optimal cost-to-performance ratios.

Challenges and Limitations in Practical Use

Metamaterials face significant challenges in scalability and manufacturing complexity compared to conventional materials, limiting their widespread practical application. Their sensitivity to environmental factors such as temperature and frequency variations often causes inconsistent performance, restricting usability in real-world conditions. Conventional materials, while lacking tunable properties, offer reliability and well-understood behavior that metamaterials have yet to consistently achieve outside controlled laboratory settings.

Future Perspectives and Research Directions

Metamaterials offer unprecedented control over electromagnetic waves, enabling breakthroughs in cloaking, superlensing, and wireless power transfer that conventional materials cannot achieve. Future research will likely concentrate on tunable, multi-functional metamaterials integrating nanotechnology, quantum effects, and AI-driven design algorithms to optimize performance for telecommunications, medical imaging, and energy harvesting. Exploring scalable fabrication techniques and enhancing material robustness remains critical to transition metamaterial applications from lab prototypes to commercial technologies.

Negative Refractive Index

Metamaterials exhibit a negative refractive index by manipulating electromagnetic waves through engineered structures, unlike conventional materials which have positive refractive indices determined by their natural atomic composition.

Photonic Bandgap

Photonic bandgap in metamaterials enables precise control of light propagation by creating frequency ranges where electromagnetic waves cannot propagate, surpassing the limited optical manipulation capabilities of conventional materials.

Plasmonic Resonance

Metamaterials exploit engineered plasmonic resonance to achieve electromagnetic properties unattainable by conventional materials, enabling superior control over light-matter interactions at subwavelength scales.

Effective Medium Theory

Effective Medium Theory quantifies the macroscopic properties of metamaterials by averaging the electromagnetic responses of their subwavelength structures, enabling engineered behaviors unattainable with conventional materials.

Anisotropic Properties

Metamaterials exhibit highly tunable anisotropic properties unlike conventional materials, enabling precise control of electromagnetic waves for advanced applications such as cloaking, sensing, and imaging.

Subwavelength Structuring

Metamaterials leverage subwavelength structuring to achieve electromagnetic properties unattainable by conventional materials, enabling precise control over wave propagation and resonance beyond natural material limits.

Tunable Permittivity

Metamaterials exhibit tunable permittivity through engineered structures enabling dynamic electromagnetic response control, surpassing the fixed permittivity limitations of conventional materials.

Homogenization Techniques

Metamaterials achieve unique electromagnetic properties through advanced homogenization techniques that model their subwavelength structure, surpassing the effective medium approximations used for conventional materials.

Frequency Selective Surfaces

Frequency Selective Surfaces in metamaterials exhibit tunable electromagnetic properties and enhanced wave manipulation capabilities compared to conventional materials, enabling advanced applications in filtering, sensing, and stealth technology.

Topological Insulators

Topological insulators in metamaterials exhibit unique electronic surface states resistant to scattering, enabling advanced applications beyond the limitations of conventional materials' bulk conductivity.

Metamaterials vs Conventional Materials Infographic

njnir.com

njnir.com