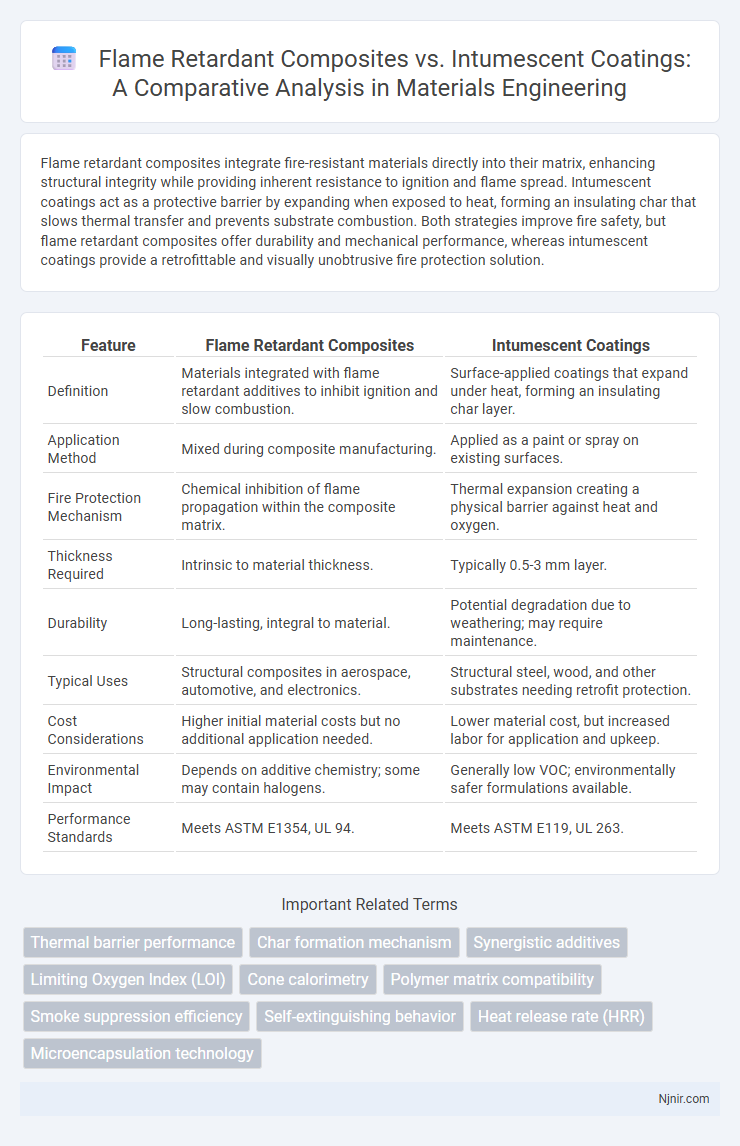

Flame retardant composites integrate fire-resistant materials directly into their matrix, enhancing structural integrity while providing inherent resistance to ignition and flame spread. Intumescent coatings act as a protective barrier by expanding when exposed to heat, forming an insulating char that slows thermal transfer and prevents substrate combustion. Both strategies improve fire safety, but flame retardant composites offer durability and mechanical performance, whereas intumescent coatings provide a retrofittable and visually unobtrusive fire protection solution.

Table of Comparison

| Feature | Flame Retardant Composites | Intumescent Coatings |

|---|---|---|

| Definition | Materials integrated with flame retardant additives to inhibit ignition and slow combustion. | Surface-applied coatings that expand under heat, forming an insulating char layer. |

| Application Method | Mixed during composite manufacturing. | Applied as a paint or spray on existing surfaces. |

| Fire Protection Mechanism | Chemical inhibition of flame propagation within the composite matrix. | Thermal expansion creating a physical barrier against heat and oxygen. |

| Thickness Required | Intrinsic to material thickness. | Typically 0.5-3 mm layer. |

| Durability | Long-lasting, integral to material. | Potential degradation due to weathering; may require maintenance. |

| Typical Uses | Structural composites in aerospace, automotive, and electronics. | Structural steel, wood, and other substrates needing retrofit protection. |

| Cost Considerations | Higher initial material costs but no additional application needed. | Lower material cost, but increased labor for application and upkeep. |

| Environmental Impact | Depends on additive chemistry; some may contain halogens. | Generally low VOC; environmentally safer formulations available. |

| Performance Standards | Meets ASTM E1354, UL 94. | Meets ASTM E119, UL 263. |

Introduction to Fire Protection in Materials Engineering

Flame retardant composites incorporate reactive or additive chemicals within the material matrix to inhibit ignition and slow combustion, offering intrinsic fire resistance essential in aerospace and construction industries. Intumescent coatings form a protective char layer upon exposure to heat, creating an insulating barrier that delays heat transfer and structural failure in steel and other substrates. Both methods are critical in materials engineering for enhancing fire protection, with composites providing built-in resistance and intumescent coatings offering adaptable, retrofit fireproofing solutions.

Overview of Flame Retardant Composites

Flame retardant composites combine polymer matrices with flame retardant additives, enhancing fire resistance by reducing flammability and smoke production while maintaining mechanical properties. These composites often incorporate materials such as aluminum trihydrate, magnesium hydroxide, or phosphorus-based compounds to achieve superior thermal stability and reduced ignition propensity. In contrast to intumescent coatings, which form protective char layers upon heat exposure, flame retardant composites provide integral fire protection throughout the material's structure, making them ideal for high-performance applications in aerospace, automotive, and construction industries.

Fundamentals of Intumescent Coatings

Intumescent coatings function by swelling upon exposure to heat, forming a protective char layer that insulates underlying materials from fire damage. These coatings are formulated with key components such as an acid source, a carbon source, and a blowing agent, which react synergistically during combustion to create a stable, insulating foam. Unlike flame retardant composites that incorporate fire-resistant materials throughout the matrix, intumescent coatings provide a reactive barrier on surfaces, offering effective thermal protection and reducing flammability in structural applications.

Mechanisms of Fire Resistance: Composites vs Intumescents

Flame retardant composites inhibit fire through thermal decomposition that releases inert gases and forms char layers, reducing heat release and oxygen supply. Intumescent coatings work by swelling and forming an insulating char foam when exposed to heat, creating a physical barrier that protects underlying materials from flame and heat. Both mechanisms optimize fire resistance by limiting heat transfer and oxygen access, but composites integrate fire-retardant properties within the material structure while intumescents act as external protective layers.

Material Selection Criteria for Flame Retardancy

Material selection criteria for flame retardancy prioritize thermal stability, char formation, and smoke suppression in flame retardant composites compared to intumescent coatings, which rely on swelling and insulating char layer formation upon exposure to heat. Flame retardant composites often integrate additives like aluminum hydroxide or phosphorus-based compounds to enhance inherent material resistance, while intumescent coatings require binder compatibility and expansion efficiency. Evaluating mechanical properties, environmental impact, and application method further guides the choice between composite incorporation and surface-intumescent treatment.

Performance Comparison: Flame Retardant Composites vs Intumescent Coatings

Flame retardant composites exhibit inherent fire resistance through integrated chemical additives, offering consistent protection and structural integrity under high heat, while intumescent coatings provide active fire protection by expanding to form an insulating char layer that delays heat transfer and combustion. Composite materials maintain mechanical strength and resist delamination during fire exposure, whereas intumescent coatings may require regular maintenance and reapplication to ensure efficacy. Performance evaluation highlights composites' durability in demanding environments and intumescent coatings' versatility for retrofitting existing structures.

Environmental and Health Considerations

Flame retardant composites often contain halogenated or metal-based additives that may release toxic fumes and persistent organic pollutants during combustion, posing environmental and health risks. Intumescent coatings generally utilize water-based formulations with fewer hazardous chemicals, reducing volatile organic compounds (VOCs) emissions and minimizing toxic smoke production. Choosing eco-friendly intumescent coatings supports sustainable fire safety solutions by enhancing indoor air quality and facilitating safer disposal.

Application Methods and Industrial Practices

Flame retardant composites are commonly applied using molding techniques such as compression molding, injection molding, and resin transfer molding, enabling integration of flame retardant materials directly into the composite matrix for enhanced fire resistance. Intumescent coatings are typically applied via spray, brush, or roller methods and cure to form an insulating char layer upon exposure to heat, providing passive fire protection mainly on structural steel and other substrates. Industrial practices favor flame retardant composites for components requiring intrinsic flame resistance and mechanical strength, while intumescent coatings are preferred for on-site application and retrofitting in construction and manufacturing sectors.

Cost Analysis and Lifecycle Performance

Flame retardant composites typically offer a higher upfront cost due to the integration of specialized resins and additives, but deliver enhanced durability and longer lifecycle performance by maintaining structural integrity under fire conditions. Intumescent coatings, while generally lower in initial cost, require periodic reapplication and maintenance, potentially increasing total lifecycle expenses. Cost analysis favors composites for long-term projects demanding minimal upkeep, whereas intumescent coatings may be economically viable for short-term or easily accessible applications.

Future Trends in Fire-Resistant Material Technologies

Future trends in fire-resistant material technologies emphasize the integration of flame retardant composites with advanced nanomaterials to enhance thermal stability and mechanical strength. Intumescent coatings are evolving through the incorporation of bio-based polymers and smart sensors for real-time fire detection and response. Research focuses on hybrid systems combining composites and intumescent layers to achieve superior fire protection with reduced environmental impact and improved sustainability.

Thermal barrier performance

Flame retardant composites provide enhanced structural integrity under high heat, whereas intumescent coatings offer superior thermal barrier performance by expanding to form an insulating char layer that reduces heat transfer.

Char formation mechanism

Flame retardant composites generate a protective char layer through thermal degradation that insulates and slows heat transfer, whereas intumescent coatings expand upon heating to form a thick, insulating char barrier that protects underlying materials.

Synergistic additives

Synergistic additives in flame retardant composites enhance thermal stability and char formation more effectively than intumescent coatings by promoting a cooperative barrier effect that improves fire resistance and mechanical properties.

Limiting Oxygen Index (LOI)

Flame retardant composites typically exhibit higher Limiting Oxygen Index (LOI) values than intumescent coatings, indicating superior resistance to ignition in oxygen-enriched environments.

Cone calorimetry

Cone calorimetry reveals that flame retardant composites generally exhibit lower heat release rates and delayed ignition times compared to intumescent coatings, indicating superior fire performance.

Polymer matrix compatibility

Flame retardant composites exhibit superior polymer matrix compatibility due to their intrinsic integration within the polymer structure, whereas intumescent coatings primarily form external protective layers that may face adhesion challenges and limited chemical interaction with diverse polymer matrices.

Smoke suppression efficiency

Intumescent coatings demonstrate superior smoke suppression efficiency compared to flame retardant composites by expanding into a protective char layer that significantly reduces smoke release and toxic gas emissions during combustion.

Self-extinguishing behavior

Flame retardant composites demonstrate superior self-extinguishing behavior by incorporating reactive additives that inhibit flame propagation, whereas intumescent coatings rely on surface swelling to form a protective char barrier that delays ignition and reduces heat transfer.

Heat release rate (HRR)

Flame retardant composites typically reduce Heat Release Rate (HRR) by incorporating fire-resistant materials within their matrix, while intumescent coatings significantly lower HRR by forming an insulating char layer that slows heat transfer during combustion.

Microencapsulation technology

Microencapsulation technology enhances flame retardant composites by providing controlled release of fire-resistant agents, offering superior protection compared to intumescent coatings that rely on surface expansion during heat exposure.

flame retardant composites vs intumescent coatings Infographic

njnir.com

njnir.com