Flexible electronics use bendable substrates like plastic or metal foils, enabling lightweight, wearable, and foldable devices that conform to various shapes. In contrast, rigid electronics depend on traditional silicon-based materials, providing high performance and stability but limited mechanical flexibility. Advances in materials engineering aim to enhance the durability and conductivity of flexible electronics while maintaining their adaptability for diverse applications.

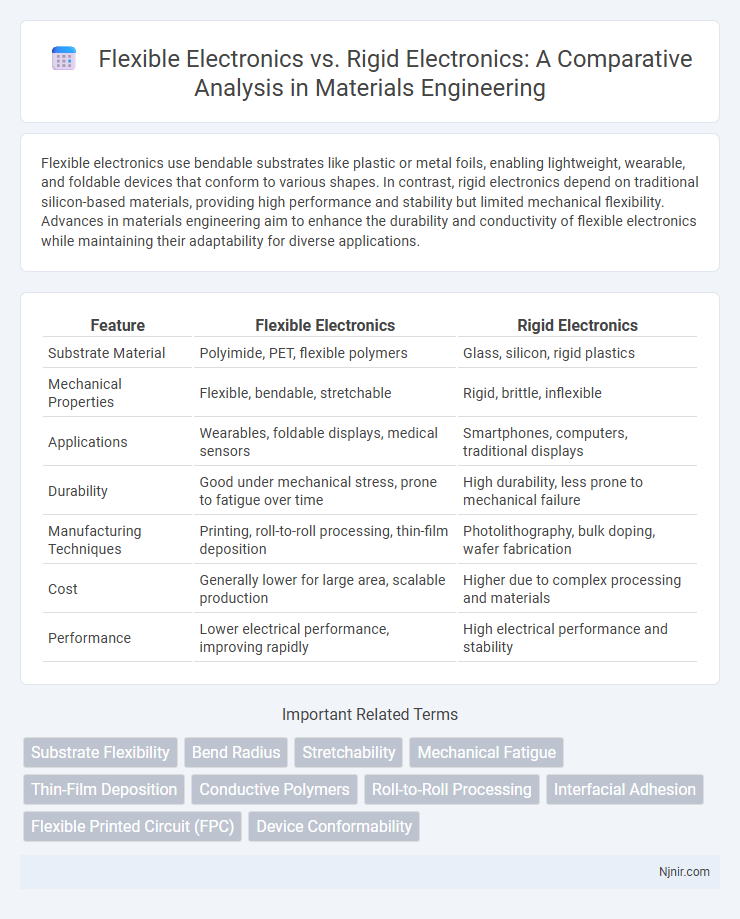

Table of Comparison

| Feature | Flexible Electronics | Rigid Electronics |

|---|---|---|

| Substrate Material | Polyimide, PET, flexible polymers | Glass, silicon, rigid plastics |

| Mechanical Properties | Flexible, bendable, stretchable | Rigid, brittle, inflexible |

| Applications | Wearables, foldable displays, medical sensors | Smartphones, computers, traditional displays |

| Durability | Good under mechanical stress, prone to fatigue over time | High durability, less prone to mechanical failure |

| Manufacturing Techniques | Printing, roll-to-roll processing, thin-film deposition | Photolithography, bulk doping, wafer fabrication |

| Cost | Generally lower for large area, scalable production | Higher due to complex processing and materials |

| Performance | Lower electrical performance, improving rapidly | High electrical performance and stability |

Introduction to Flexible and Rigid Electronics

Flexible electronics utilize bendable, stretchable materials like organic semiconductors and thin-film transistors, enabling lightweight, foldable, and wearable devices suited for dynamic applications. Rigid electronics rely on traditional silicon-based components with fixed shapes, offering high performance and durability for conventional computing, industrial, and consumer electronics. The distinction highlights trade-offs in design flexibility, mechanical stress tolerance, and application adaptability between emerging flexible systems and established rigid platforms.

Material Composition and Selection

Flexible electronics utilize materials such as organic polymers, conductive inks, and thin metal films that allow bending and stretching without compromising performance, whereas rigid electronics rely on traditional silicon-based semiconductors and rigid substrates like glass or ceramic. The selection of materials in flexible electronics emphasizes mechanical durability, lightweight properties, and integration with wearable or curved surfaces, contrasting with the high thermal stability and precision manufacturing requirements dominant in rigid electronics. Advances in nanomaterials and flexible substrates like polyimide or PET have enhanced the performance and application scope of flexible electronics, differentiating them from the rigid counterparts that prioritize robustness and longevity in fixed environments.

Fabrication Techniques

Flexible electronics utilize advanced fabrication techniques such as roll-to-roll printing, inkjet printing, and screen printing on substrates like polyimide or PET, enabling bendable, stretchable, and lightweight devices. Rigid electronics rely on traditional photolithography and etching processes on silicon wafers or glass substrates, resulting in high-precision but inflexible circuits. Emerging techniques in flexible electronics emphasize low-temperature processing and thin-film transistor integration to enhance durability and performance in wearable and foldable applications.

Mechanical Properties and Flexibility

Flexible electronics exhibit superior mechanical properties such as bendability, stretchability, and lightweight form factors, enabling them to conform to curved surfaces and withstand repetitive mechanical stress without performance degradation. Rigid electronics, typically built on hard substrates like silicon or glass, offer high structural stability but lack flexibility, making them prone to fractures or failure under bending or twisting forces. The mechanical versatility of flexible electronics allows integration into wearable devices, foldable displays, and biomedical sensors, where durability under dynamic mechanical deformation is critical.

Electrical Performance Comparison

Flexible electronics often exhibit lower electrical conductivity and slower electron mobility compared to rigid electronics due to the use of organic semiconductors and bendable substrates. Rigid electronics, typically fabricated with silicon-based materials, provide superior electrical performance, including higher signal speed, stability, and power efficiency. However, ongoing advancements in flexible material science are narrowing the gap by improving charge carrier mobility and reducing electrical resistance in flexible devices.

Application Areas: Flexible vs Rigid Electronics

Flexible electronics excel in wearable technology, medical devices, and flexible displays due to their ability to bend and adapt to various surfaces, enhancing comfort and usability. Rigid electronics dominate applications requiring high-performance computing, robust structural integrity, and stable operating environments, such as desktop computers, servers, and traditional consumer electronics. The choice between flexible and rigid electronics hinges on specific functional requirements, environmental conditions, and design constraints in sectors like healthcare, automotive, and consumer electronics.

Reliability and Durability Considerations

Flexible electronics exhibit enhanced reliability in dynamic environments due to their ability to bend, stretch, and conform without compromising functionality, making them ideal for wearable devices and evolving applications. Rigid electronics offer superior durability in static conditions with stable structural integrity and resistance to mechanical stress, preferred for traditional computing and industrial applications. Material fatigue, stress distribution, and environmental exposure significantly influence the lifespan and performance reliability in both flexible and rigid electronic systems.

Cost Analysis and Scalability

Flexible electronics typically offer lower manufacturing costs due to reduced material usage and simpler assembly processes compared to rigid electronics. However, the scalability of flexible electronics can be challenged by current limitations in mass production techniques and durability concerns. In contrast, rigid electronics benefit from mature, high-volume production lines that drive down per-unit costs, making them more scalable despite higher initial material and fabrication expenses.

Environmental Impact and Sustainability

Flexible electronics significantly reduce electronic waste by enabling devices to be more durable, lightweight, and adaptable, thereby extending product lifespan and decreasing resource consumption. Unlike rigid electronics, flexible components often use biodegradable substrates and lower amounts of toxic materials, which minimizes environmental pollution during manufacturing and disposal processes. Sustainable design in flexible electronics promotes energy efficiency and supports circular economy principles, ultimately reducing the overall carbon footprint compared to traditional rigid electronics.

Future Trends and Innovations

Flexible electronics are driving future trends with innovations such as stretchable sensors, foldable displays, and wearable health monitors, enabling seamless integration into textiles and curved surfaces. Rigid electronics continue to evolve with advancements in miniaturization and increased processing power, supporting high-performance applications like AI computing and 5G infrastructure. The convergence of flexible and rigid technologies is expected to create hybrid devices combining durability with adaptability, transforming consumer electronics and medical devices.

Substrate Flexibility

Flexible electronics use bendable substrates like polyimide or PET to enable durability and conformability, whereas rigid electronics rely on inflexible substrates such as silicon wafers that limit their adaptability.

Bend Radius

Flexible electronics feature a significantly smaller bend radius, often below 1 mm, enabling durable, lightweight, and compact devices compared to rigid electronics with minimal or no bend tolerance.

Stretchability

Flexible electronics exhibit superior stretchability compared to rigid electronics, enabling enhanced durability and adaptability in wearable devices and foldable displays.

Mechanical Fatigue

Flexible electronics demonstrate superior resistance to mechanical fatigue compared to rigid electronics due to their ability to bend, stretch, and conform without damaging internal components.

Thin-Film Deposition

Thin-film deposition techniques in flexible electronics enable lightweight, bendable devices by using substrates like plastic or metal foils, whereas rigid electronics rely on conventional deposition on inflexible silicon wafers, affecting device durability and application scope.

Conductive Polymers

Conductive polymers in flexible electronics enable lightweight, bendable devices with enhanced durability and stretchability compared to the brittle, inflexible materials used in rigid electronics.

Roll-to-Roll Processing

Roll-to-roll processing revolutionizes flexible electronics manufacturing by enabling continuous, high-throughput production on bendable substrates, contrasting with the batch-based, limited scalability methods used in rigid electronics fabrication.

Interfacial Adhesion

Interfacial adhesion in flexible electronics is engineered to maintain strong, durable bonds under bending and stretching, contrasting with rigid electronics where adhesion primarily withstands static mechanical stress.

Flexible Printed Circuit (FPC)

Flexible Printed Circuit (FPC) technology enables lightweight, bendable electronics with enhanced durability and space efficiency compared to traditional rigid electronics, revolutionizing wearable devices and flexible displays.

Device Conformability

Flexible electronics exhibit superior device conformability compared to rigid electronics, enabling seamless integration with curved or irregular surfaces for advanced wearable and biomedical applications.

Flexible Electronics vs Rigid Electronics Infographic

njnir.com

njnir.com