Biodegradable polymers offer a sustainable alternative to traditional plastics by breaking down naturally through microbial activity, reducing long-term environmental pollution. These materials are derived from renewable resources and often exhibit comparable mechanical properties, making them suitable for various applications. Incorporating biodegradable polymers into product design addresses plastic waste accumulation while promoting eco-friendly manufacturing practices.

Table of Comparison

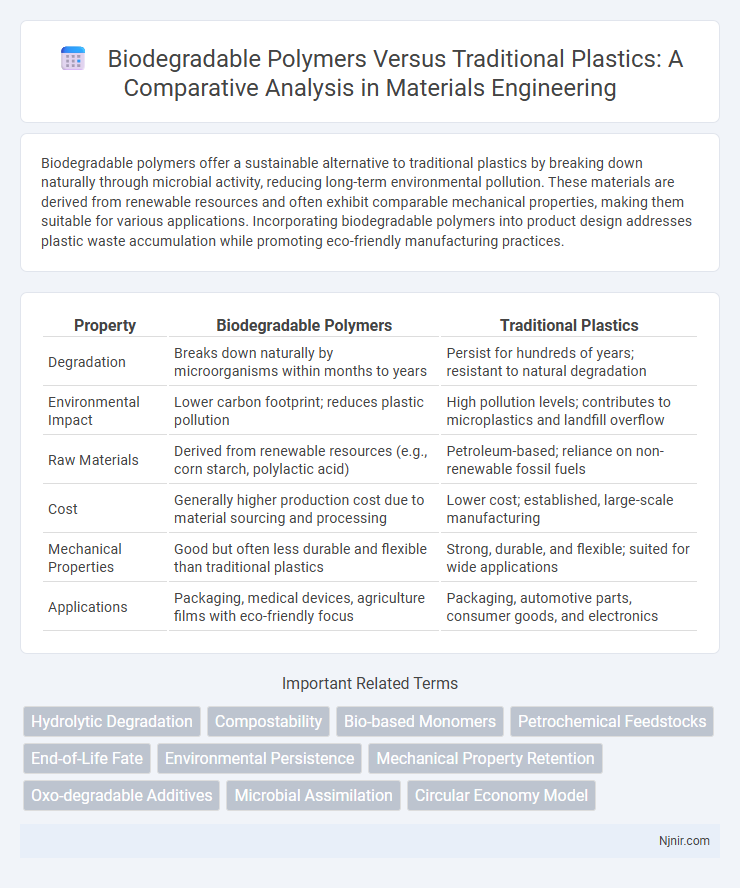

| Property | Biodegradable Polymers | Traditional Plastics |

|---|---|---|

| Degradation | Breaks down naturally by microorganisms within months to years | Persist for hundreds of years; resistant to natural degradation |

| Environmental Impact | Lower carbon footprint; reduces plastic pollution | High pollution levels; contributes to microplastics and landfill overflow |

| Raw Materials | Derived from renewable resources (e.g., corn starch, polylactic acid) | Petroleum-based; reliance on non-renewable fossil fuels |

| Cost | Generally higher production cost due to material sourcing and processing | Lower cost; established, large-scale manufacturing |

| Mechanical Properties | Good but often less durable and flexible than traditional plastics | Strong, durable, and flexible; suited for wide applications |

| Applications | Packaging, medical devices, agriculture films with eco-friendly focus | Packaging, automotive parts, consumer goods, and electronics |

Introduction to Biodegradable Polymers and Traditional Plastics

Biodegradable polymers are materials designed to break down naturally through microbial activity, reducing environmental impact by decomposing into water, carbon dioxide, and biomass. Traditional plastics, derived primarily from petrochemicals, consist of long-lasting polymers resistant to degradation, leading to persistent pollution in ecosystems. The key distinction lies in their molecular structure, which governs their decomposition rate and ecological footprint.

Chemical Structure and Composition Differences

Biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) have ester linkages in their backbone, enabling enzymatic hydrolysis and microbial degradation, unlike traditional plastics like polyethylene (PE) and polypropylene (PP) that consist of long carbon-carbon chains resistant to biodegradation. The presence of oxygen atoms within the polymer backbone of biodegradable polymers introduces polar sites that facilitate water absorption and subsequent breakdown, whereas traditional plastics are composed primarily of non-polar, hydrophobic hydrocarbons. This fundamental difference in chemical composition accounts for the improved environmental compatibility of biodegradable polymers through accelerated degradation under natural conditions.

Sources: Renewable vs Petrochemical Origins

Biodegradable polymers are primarily derived from renewable sources such as corn starch, sugarcane, and cellulose, making them environmentally sustainable alternatives to traditional plastics. Traditional plastics are predominantly synthesized from petrochemical origins, including crude oil and natural gas, contributing to finite resource depletion and long-lasting pollution. The renewable nature of biodegradable polymers enables lower carbon footprints and promotes circular economy principles compared to the fossil-fuel dependence of conventional plastics.

Mechanical and Physical Property Comparison

Biodegradable polymers typically exhibit lower tensile strength and reduced impact resistance compared to traditional plastics like polyethylene and polypropylene, impacting their suitability for high-stress applications. These polymers often possess higher water absorption rates and lower thermal stability, which can affect durability and processing temperatures. Despite these limitations, advancements in polymer blending and additives are improving their mechanical performance and expanding their usability in packaging and disposable products.

Environmental Impact and Degradation Pathways

Biodegradable polymers significantly reduce environmental impact by breaking down into natural substances through microbial activity, composting, or enzymatic processes, unlike traditional plastics which persist for centuries and contribute to landfill accumulation and marine pollution. Their degradation pathways involve hydrolysis, oxidation, and microbial assimilation that convert polymers into carbon dioxide, water, and biomass without releasing toxic residues. Traditional plastics primarily degrade via photodegradation and mechanical fragmentation, resulting in microplastics that pose long-term ecological and health risks.

Applications in Packaging and Consumer Goods

Biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are increasingly used in packaging and consumer goods due to their ability to decompose naturally, reducing environmental impact compared to traditional plastics like polyethylene and polypropylene. These materials are suitable for single-use items, food containers, and compostable bags, offering sustainable alternatives that meet regulatory standards for biodegradability and safety in food contact applications. Market growth in biodegradable polymers is driven by rising consumer demand for eco-friendly packaging and stricter government regulations on plastic waste management.

Challenges in Processing and Manufacturing

Biodegradable polymers face significant challenges in processing and manufacturing, including sensitivity to heat and moisture, which can degrade material properties during extrusion and molding. Traditional plastics benefit from established high-temperature processing techniques that ensure consistent mechanical strength but contribute to environmental persistence. The variability in feedstock quality for biodegradable polymers also complicates scaling production and achieving uniform product performance compared to the predictability of fossil-fuel-based plastics.

Lifecycle Assessment and End-of-Life Scenarios

Biodegradable polymers demonstrate a significantly lower environmental impact during lifecycle assessment compared to traditional plastics, primarily due to their ability to break down naturally in composting or anaerobic digestion environments. Traditional plastics often persist in landfills and oceans for hundreds of years, contributing to long-term pollution and microplastic formation, whereas biodegradable alternatives reduce carbon footprint and minimize waste accumulation. End-of-life scenarios for biodegradable polymers prioritize compostability and renewable resource recovery, contrasting with traditional plastics that rely heavily on recycling or disposal methods that do not effectively mitigate environmental damage.

Regulatory Standards and Certifications

Biodegradable polymers comply with emerging regulatory standards emphasizing environmental impact, such as ASTM D6400 and EN 13432 certifications, which ensure materials break down under industrial composting conditions. Traditional plastics often lack these certifications, reflecting their resistance to degradation and contribution to long-term pollution. Regulatory frameworks increasingly mandate labeling and certification for biodegradable polymers to promote sustainable waste management and reduce plastic pollution in ecosystems.

Future Trends and Innovations in Polymer Technology

Future trends in polymer technology emphasize the development of biodegradable polymers derived from renewable resources, enhancing environmental sustainability while maintaining performance. Innovations include advanced enzymatic degradation techniques and bio-based copolymers that improve mechanical strength and accelerate decomposition rates compared to traditional plastics. Emerging technologies also focus on integrating sensor functionalities and recyclability to create smart, eco-friendly materials that address current plastic pollution challenges.

Hydrolytic Degradation

Hydrolytic degradation in biodegradable polymers accelerates environmental breakdown by cleaving polymer chains with water molecules, unlike traditional plastics which resist hydrolytic processes due to their stable chemical structures.

Compostability

Biodegradable polymers demonstrate superior compostability compared to traditional plastics, breaking down efficiently into natural elements within controlled composting environments.

Bio-based Monomers

Bio-based monomers derived from renewable resources enable biodegradable polymers to reduce environmental impact compared to traditional plastics made from fossil-fuel-based monomers.

Petrochemical Feedstocks

Biodegradable polymers derived from renewable biomass offer a sustainable alternative to traditional plastics primarily produced from non-renewable petrochemical feedstocks like crude oil and natural gas.

End-of-Life Fate

Biodegradable polymers degrade into natural compounds through microbial action under composting conditions, whereas traditional plastics persist in the environment for centuries due to their resistance to biodegradation.

Environmental Persistence

Biodegradable polymers decompose within months to years in natural environments, significantly reducing environmental persistence compared to traditional plastics, which can persist for centuries and contribute to long-term pollution.

Mechanical Property Retention

Biodegradable polymers retain mechanical properties less effectively than traditional plastics, exhibiting lower tensile strength and durability under long-term stress conditions.

Oxo-degradable Additives

Oxo-degradable additives accelerate the fragmentation of traditional plastics but do not ensure complete biodegradation, posing environmental risks compared to fully biodegradable polymers.

Microbial Assimilation

Biodegradable polymers undergo microbial assimilation more efficiently than traditional plastics, leading to faster decomposition and reduced environmental impact.

Circular Economy Model

Biodegradable polymers support the circular economy model by enhancing material recovery and reducing plastic waste, unlike traditional plastics that contribute to long-term environmental pollution.

Biodegradable Polymers vs Traditional Plastics Infographic

njnir.com

njnir.com