Friction stir welding (FSW) offers superior joint strength and minimal distortion due to its solid-state process, making it ideal for joining lightweight alloys and sensitive materials. Laser welding, characterized by high precision and rapid processing speeds, excels in applications requiring intricate welds and minimal heat-affected zones. Selecting between FSW and laser welding depends on factors such as material type, joint design, and production volume, with FSW favored for robustness and laser welding preferred for fine detail and speed.

Table of Comparison

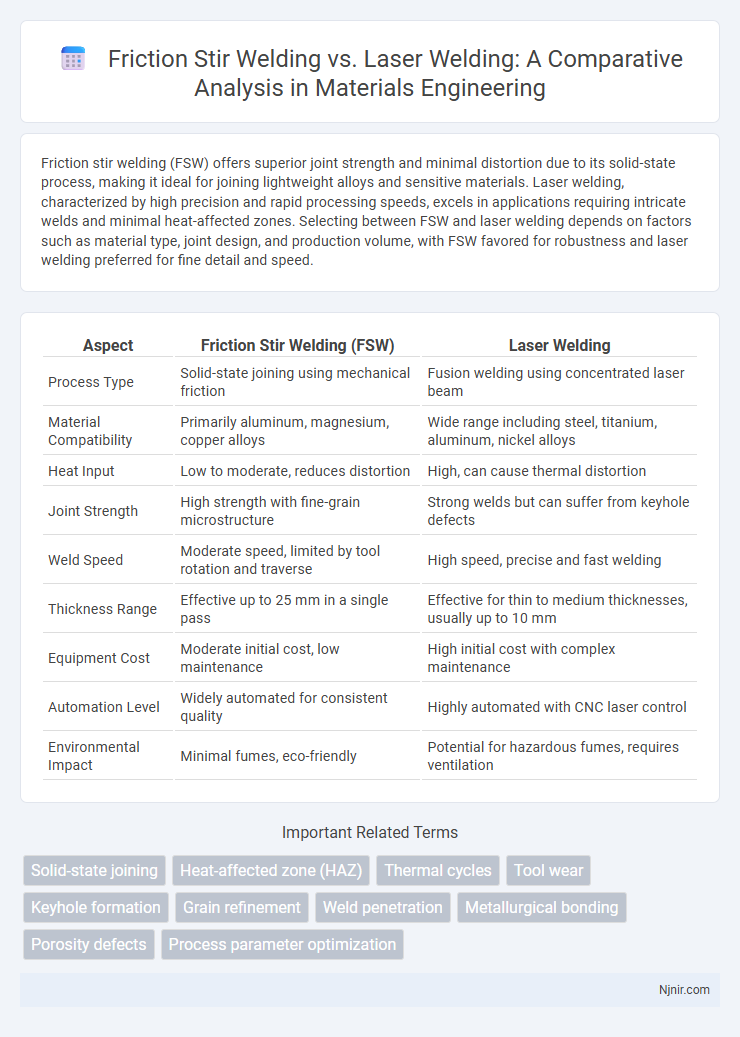

| Aspect | Friction Stir Welding (FSW) | Laser Welding |

|---|---|---|

| Process Type | Solid-state joining using mechanical friction | Fusion welding using concentrated laser beam |

| Material Compatibility | Primarily aluminum, magnesium, copper alloys | Wide range including steel, titanium, aluminum, nickel alloys |

| Heat Input | Low to moderate, reduces distortion | High, can cause thermal distortion |

| Joint Strength | High strength with fine-grain microstructure | Strong welds but can suffer from keyhole defects |

| Weld Speed | Moderate speed, limited by tool rotation and traverse | High speed, precise and fast welding |

| Thickness Range | Effective up to 25 mm in a single pass | Effective for thin to medium thicknesses, usually up to 10 mm |

| Equipment Cost | Moderate initial cost, low maintenance | High initial cost with complex maintenance |

| Automation Level | Widely automated for consistent quality | Highly automated with CNC laser control |

| Environmental Impact | Minimal fumes, eco-friendly | Potential for hazardous fumes, requires ventilation |

Overview of Friction Stir Welding and Laser Welding

Friction Stir Welding (FSW) is a solid-state joining process that uses a rotating tool to generate frictional heat and mechanically mix materials without reaching their melting point, primarily suited for aluminum alloys and other metals. Laser Welding (LW) employs a concentrated laser beam to melt and fuse materials, enabling high-precision, high-speed welding of metals including steel, titanium, and nickel-based alloys. FSW offers advantages in joining thicker sections with minimal distortion, while LW excels in applications requiring narrow weld seams and automation flexibility.

Fundamental Principles and Mechanisms

Friction stir welding (FSW) relies on mechanical stirring through a rotating tool that generates heat via friction to plastically deform and join materials without melting. Laser welding uses a focused laser beam to deliver high-intensity thermal energy, melting and fusing the workpieces at the joint interface. FSW produces solid-state bonds with fine-grained microstructures, while laser welding creates fusion zones with distinct melting and solidification mechanisms.

Suitable Materials and Material Limitations

Friction stir welding is highly effective for joining aluminum alloys, copper, magnesium, and other soft metals, but it struggles with very hard or brittle materials due to tool wear and limited heat input. Laser welding excels with a broader range of metals, including stainless steel, titanium, and high-strength alloys, offering precise control for thin materials but faces challenges with reflective or highly conductive metals like copper. Material thickness and surface condition critically affect laser welding quality, whereas friction stir welding is more tolerant of surface contaminants but limited to materials that allow plastic deformation.

Process Parameters: Control and Optimization

Friction stir welding (FSW) requires precise control of parameters such as tool rotation speed, travel speed, and plunge depth to optimize joint strength and minimize defects. Laser welding demands accurate adjustment of laser power, beam focus, and welding speed to achieve deep penetration and narrow heat-affected zones. Both processes benefit from real-time monitoring systems and adaptive control algorithms to ensure consistent weld quality and process stability.

Joint Quality and Mechanical Properties

Friction stir welding (FSW) delivers superior joint quality with minimal distortion and excellent control over microstructure, resulting in enhanced mechanical properties such as increased tensile strength and fatigue resistance. Laser welding offers high precision and speed but can introduce defects like porosity or hot cracking, which may compromise joint integrity and mechanical performance. The choice between FSW and laser welding depends on the specific application requirements for joint strength, durability, and material thickness.

Microstructural Evolution and Metallurgical Effects

Friction stir welding (FSW) induces significant grain refinement and dynamic recrystallization in the stir zone due to severe plastic deformation and frictional heat, resulting in a fine, equiaxed microstructure with reduced porosity and improved mechanical properties. In contrast, laser welding produces rapid melting and solidification, leading to a heat-affected zone with coarse dendritic grains and potential segregation or keyhole porosity, which can negatively affect weld integrity. Metallurgically, FSW maintains base metal phases with minimal phase transformation, whereas laser welding often causes fusion zone solidification microstructures with increased residual stresses and possible phase precipitation.

Thermal Effects and Heat-Affected Zone Comparison

Friction stir welding generates heat through mechanical friction and plastic deformation, resulting in a relatively low peak temperature and a narrower heat-affected zone (HAZ) compared to laser welding. Laser welding produces a highly concentrated heat source causing rapid melting and solidification, which creates a wider HAZ with potential for greater thermal distortion and residual stress. The minimal HAZ in friction stir welding preserves base material properties better, while laser welding offers faster processing but requires careful heat input control to avoid detrimental thermal effects.

Applications in Industry and Case Studies

Friction stir welding (FSW) is widely employed in aerospace, automotive, and shipbuilding industries due to its ability to join lightweight aluminum alloys with high strength and low distortion. Laser welding finds extensive applications in electronics, medical device manufacturing, and precision automotive components, offering high-speed and precise welds on thin materials and dissimilar metals. Case studies highlight FSW's success in producing fuel-efficient aircraft panels while laser welding is favored for micro-welds in medical implants, demonstrating distinct advantages aligned with industrial requirements.

Environmental Impact and Energy Efficiency

Friction stir welding (FSW) demonstrates a significantly lower environmental impact due to its solid-state process, which eliminates the need for filler materials and reduces harmful emissions compared to laser welding. FSW consumes less energy overall because it operates at lower temperatures and requires no shielding gases, unlike laser welding, which demands high-power lasers and extensive cooling systems. The energy efficiency of FSW translates into reduced carbon footprint and operational costs, making it a more sustainable option for metal joining in automotive and aerospace industries.

Cost Analysis and Scalability

Friction stir welding (FSW) generally offers lower operational costs due to minimal consumables and energy consumption, making it cost-effective for medium to large-scale production of aluminum and similar alloys. Laser welding requires significant initial investment in high-powered laser equipment and precise automation but excels in scalability for complex geometries and materials, allowing rapid processing speeds and integration into high-volume manufacturing lines. Cost analysis must consider material type, production volume, and part complexity, where FSW suits thicker sections and moderate scale, while laser welding is optimal for thin materials and high-throughput applications.

Solid-state joining

Friction stir welding offers a solid-state joining process that produces defect-free, high-strength joints through mechanical stirring without melting, whereas laser welding, often involving partial melting, achieves high precision but may introduce thermal distortions.

Heat-affected zone (HAZ)

Friction stir welding produces a narrower and less thermally distorted heat-affected zone (HAZ) compared to laser welding, which generates a larger HAZ due to higher localized temperatures.

Thermal cycles

Friction stir welding generates lower peak temperatures and more uniform thermal cycles than laser welding, resulting in reduced residual stresses and minimized distortion in joined materials.

Tool wear

Friction stir welding experiences significant tool wear due to intense mechanical stress and heat, whereas laser welding minimizes tool wear by utilizing a non-contact, high-energy beam for material fusion.

Keyhole formation

Keyhole formation in laser welding enables deep, narrow welds by vaporizing material, while friction stir welding avoids keyholes by mechanically mixing solids through a rotating tool.

Grain refinement

Friction stir welding achieves superior grain refinement by mechanically stirring and recrystallizing the metal, producing finer and more uniform grain structures compared to laser welding's rapid thermal cycles that often result in coarser grains.

Weld penetration

Friction stir welding achieves deeper weld penetration with minimal thermal distortion compared to laser welding, which offers precise but often shallower penetration ideal for thin materials.

Metallurgical bonding

Friction stir welding creates a solid-state metallurgical bond with refined grain structures and minimal defects, while laser welding forms a fusion bond characterized by rapid cooling rates and potential microstructural heterogeneity.

Porosity defects

Friction stir welding typically exhibits lower porosity defects compared to laser welding, as its solid-state process minimizes gas entrapment and void formation.

Process parameter optimization

Friction stir welding requires precise optimization of rotational speed, travel speed, and plunge depth to ensure defect-free joints, while laser welding demands fine-tuning of laser power, welding speed, and focal position for optimal penetration and minimal thermal distortion.

friction stir welding vs laser welding Infographic

njnir.com

njnir.com