Self-healing polymers exhibit the ability to autonomously repair damage through reversible chemical bonds or microcapsule release, enhancing material longevity and reducing maintenance costs. Shape-memory alloys, characterized by their ability to return to a predefined shape upon heating, provide exceptional mechanical strength and durability in dynamic environments. Comparing these materials reveals that self-healing polymers prioritize damage repair and flexibility, while shape-memory alloys emphasize structural recovery and thermal responsiveness.

Table of Comparison

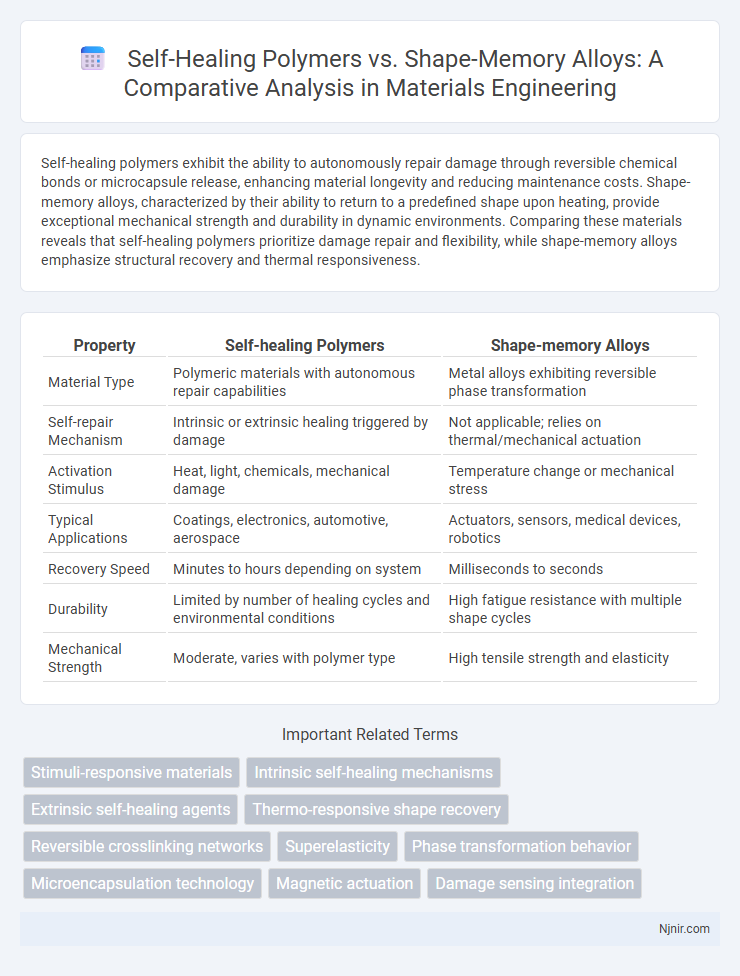

| Property | Self-healing Polymers | Shape-memory Alloys |

|---|---|---|

| Material Type | Polymeric materials with autonomous repair capabilities | Metal alloys exhibiting reversible phase transformation |

| Self-repair Mechanism | Intrinsic or extrinsic healing triggered by damage | Not applicable; relies on thermal/mechanical actuation |

| Activation Stimulus | Heat, light, chemicals, mechanical damage | Temperature change or mechanical stress |

| Typical Applications | Coatings, electronics, automotive, aerospace | Actuators, sensors, medical devices, robotics |

| Recovery Speed | Minutes to hours depending on system | Milliseconds to seconds |

| Durability | Limited by number of healing cycles and environmental conditions | High fatigue resistance with multiple shape cycles |

| Mechanical Strength | Moderate, varies with polymer type | High tensile strength and elasticity |

Introduction to Smart Materials in Engineering

Self-healing polymers and shape-memory alloys represent two pivotal categories of smart materials in engineering, characterized by their ability to autonomously recover from damage and adapt to external stimuli, respectively. Self-healing polymers utilize embedded microcapsules or dynamic covalent bonds to repair cracks, enhancing longevity and reducing maintenance costs in structural applications. Shape-memory alloys, primarily composed of nickel-titanium, exhibit phase transformations that enable them to return to predefined shapes under thermal or mechanical triggers, making them indispensable in aerospace and biomedical devices.

Fundamental Principles of Self-healing Polymers

Self-healing polymers autonomously repair damage through reversible chemical bonds or dynamic covalent networks that restore material integrity without external intervention. These polymers utilize mechanisms such as microcapsule rupture, reversible Diels-Alder reactions, or hydrogen bonding to enable healing at molecular or supramolecular levels. Unlike shape-memory alloys that rely on phase transformations for shape recovery, self-healing polymers focus on chemical and physical processes to mend cracks and extend material lifespan.

Core Mechanisms of Shape-memory Alloys

Shape-memory alloys (SMAs) exhibit unique core mechanisms based on reversible martensitic phase transformations, allowing them to recover predefined shapes after deformation when exposed to specific temperatures. Their phase change between austenite and martensite phases enables superelasticity and the shape memory effect, fundamental for applications requiring precise actuation and stress recovery. Unlike self-healing polymers, which rely on molecular bond reformation or dynamic covalent chemistry, SMAs' transformation-driven behavior provides robust mechanical performance and reproducibility.

Comparative Healing Capabilities

Self-healing polymers exhibit the ability to autonomously repair microcracks and restore structural integrity through reversible chemical bonds or embedded healing agents, enabling repeated damage recovery without external intervention. Shape-memory alloys rely on phase transformations between martensite and austenite phases to recover predefined shapes after deformation, but their healing capacity is limited to shape restoration rather than material repair. Consequently, self-healing polymers provide superior intrinsic healing capabilities by restoring both mechanical properties and microstructure, whereas shape-memory alloys primarily offer mechanical shape recovery without true material self-repair.

Mechanical Performance Under Stress

Self-healing polymers demonstrate superior mechanical performance under cyclic stress by autonomously repairing microcracks, thereby maintaining structural integrity and extending material lifespan. Shape-memory alloys exhibit high strength and elasticity, recovering their original shape after deformation but often suffer from fatigue failure under repeated stress cycles. The choice between these materials depends on application-specific requirements for durability, flexibility, and damage tolerance in dynamic environments.

Applications in Industrial Sectors

Self-healing polymers are extensively utilized in coatings, electronics, and automotive sectors due to their ability to autonomously repair micro-cracks, enhancing durability and reducing maintenance costs. Shape-memory alloys find critical applications in aerospace, robotics, and medical devices, where their unique property to return to a predefined shape under temperature variation enables precise actuation and structural adaptability. Industrial deployment of self-healing polymers emphasizes longevity and sustainability, while shape-memory alloys drive innovation in smart structures and responsive mechanisms.

Sustainability and Environmental Impact

Self-healing polymers offer significant sustainability advantages by reducing material waste and extending product lifespans through autonomous damage repair, lowering the environmental footprint compared to traditional materials. Shape-memory alloys, while durable and recyclable, typically require energy-intensive production processes and rely on rare metals, which raises concerns regarding resource depletion and environmental impact. Prioritizing self-healing polymers in applications can enhance eco-friendly design by minimizing landfill contributions and energy consumption during manufacturing and maintenance.

Cost-effectiveness and Scalability

Self-healing polymers offer cost-effective production due to low material expenses and simpler manufacturing processes, making them scalable for mass-market applications across automotive and electronics industries. Shape-memory alloys, while providing superior mechanical properties and durability, incur higher costs driven by expensive raw materials like nickel-titanium and complex fabrication techniques, limiting their widespread scalability. Evaluating total lifecycle costs reveals that self-healing polymers are preferable for economically scalable solutions, whereas shape-memory alloys excel in high-performance, specialized applications despite higher initial investment.

Future Research Directions

Future research directions in self-healing polymers focus on enhancing healing efficiency, extending lifespan, and integrating stimuli-responsive mechanisms for real-time damage repair in aerospace and electronics. Shape-memory alloys require advancements in alloy composition and microstructure control to improve fatigue resistance and reduce activation temperatures for biomedical and robotics applications. Combining self-healing polymers with shape-memory alloys presents an innovative approach to develop multifunctional materials with adaptive and reparative properties for next-generation smart devices.

Conclusion: Choosing the Right Smart Material

Self-healing polymers offer enhanced durability through autonomous damage repair, making them ideal for applications requiring long-term material integrity with minimal maintenance. Shape-memory alloys provide exceptional mechanical strength and precise shape recovery, suited for environments demanding rapid responsiveness and high load-bearing capacity. Selecting the right smart material depends on balancing factors such as repairability, mechanical performance, and specific application requirements.

Stimuli-responsive materials

Self-healing polymers autonomously repair damage through chemical or physical stimuli, while shape-memory alloys reversibly change shape in response to thermal or mechanical stimuli, both advancing stimuli-responsive material technologies.

Intrinsic self-healing mechanisms

Intrinsic self-healing polymers autonomously repair molecular damage through reversible covalent bonds or dynamic supramolecular interactions, contrasting with shape-memory alloys that rely on phase transformations without inherent material regeneration.

Extrinsic self-healing agents

Extrinsic self-healing agents in polymers provide targeted damage repair through embedded microcapsules or vascular networks, contrasting with shape-memory alloys that rely on temperature-induced phase transformations for recovery without embedded healing components.

Thermo-responsive shape recovery

Thermo-responsive shape recovery in shape-memory alloys enables rapid and reversible transformation at specific temperatures, while self-healing polymers offer autonomous repair through thermal activation, enhancing durability and lifespan in smart materials.

Reversible crosslinking networks

Self-healing polymers with reversible crosslinking networks enable autonomous repair through dynamic bond reformation, whereas shape-memory alloys rely on phase transformations for shape recovery without intrinsic self-repair capabilities.

Superelasticity

Superelasticity in shape-memory alloys enables reversible large strains through phase transformations, whereas self-healing polymers offer damage repair but typically lack the pronounced superelastic behavior of shape-memory alloys.

Phase transformation behavior

Self-healing polymers exhibit autonomous repair through reversible chemical bonds and dynamic crosslinking, while shape-memory alloys rely on martensitic phase transformations between austenite and martensite phases to recover pre-deformed shapes.

Microencapsulation technology

Microencapsulation technology in self-healing polymers enables autonomous repair by releasing healing agents upon damage, offering superior durability compared to the reversible deformation properties of shape-memory alloys.

Magnetic actuation

Magnetic actuation enables self-healing polymers to autonomously repair damage through embedded magnetic nanoparticles, whereas shape-memory alloys rely on magnetic fields to trigger phase transformations and restore predefined shapes.

Damage sensing integration

Self-healing polymers incorporate embedded microcapsules or conductive networks for real-time damage sensing, whereas shape-memory alloys rely on changes in electrical resistance or thermomechanical properties to detect and respond to structural damage.

Self-healing Polymers vs Shape-memory Alloys Infographic

njnir.com

njnir.com