Top-down synthesis involves breaking down bulk materials into nanostructures through methods like lithography and milling, which offers precise control over shape but may introduce defects. Bottom-up synthesis builds materials atom-by-atom or molecule-by-molecule, enabling the creation of highly uniform nanostructures with fewer imperfections. Choosing between these approaches depends on the desired material properties, scalability, and application requirements in materials engineering.

Table of Comparison

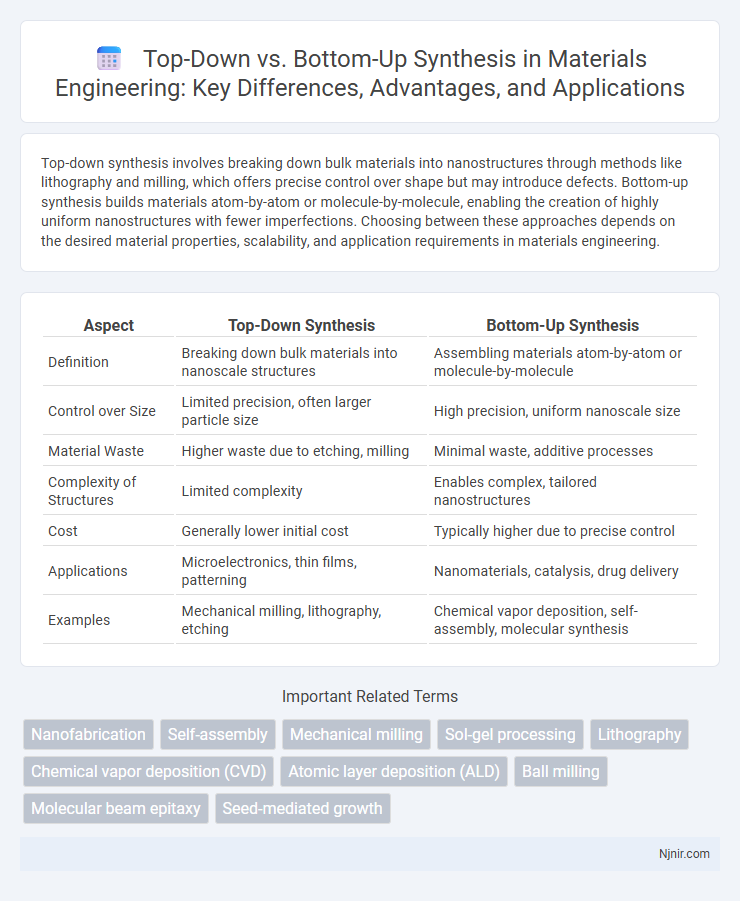

| Aspect | Top-Down Synthesis | Bottom-Up Synthesis |

|---|---|---|

| Definition | Breaking down bulk materials into nanoscale structures | Assembling materials atom-by-atom or molecule-by-molecule |

| Control over Size | Limited precision, often larger particle size | High precision, uniform nanoscale size |

| Material Waste | Higher waste due to etching, milling | Minimal waste, additive processes |

| Complexity of Structures | Limited complexity | Enables complex, tailored nanostructures |

| Cost | Generally lower initial cost | Typically higher due to precise control |

| Applications | Microelectronics, thin films, patterning | Nanomaterials, catalysis, drug delivery |

| Examples | Mechanical milling, lithography, etching | Chemical vapor deposition, self-assembly, molecular synthesis |

Introduction to Synthesis Approaches in Materials Engineering

Top-Down and Bottom-Up synthesis are fundamental approaches in materials engineering for fabricating nanomaterials and microstructures. Top-Down synthesis involves breaking down bulk materials into nanoscale structures using techniques like lithography or milling, enabling precise size and shape control. Bottom-Up synthesis assembles materials atom-by-atom or molecule-by-molecule, such as chemical vapor deposition or sol-gel processes, allowing for atomic-level customization and novel properties.

Fundamentals of Top-Down Synthesis Methods

Top-Down Synthesis methods involve the fabrication of nanomaterials by breaking down bulk materials into smaller structures using techniques such as lithography, etching, and milling. These methods rely on precise control of shape and size by physically sculpting the material, allowing for well-defined nanostructures with high reproducibility. The fundamental processes include mechanical, chemical, or physical removal of material to achieve nanoscale features, contrasting with Bottom-Up approaches that build structures atom-by-atom or molecule-by-molecule.

Core Principles of Bottom-Up Synthesis Techniques

Bottom-up synthesis techniques build complex nanostructures by assembling atoms or molecules through controlled chemical reactions, relying on principles of self-assembly and molecular recognition. These methods emphasize precise manipulation at the atomic or molecular level to create uniform, well-defined nanomaterials with tailored properties. Core principles include nucleation and growth control, surface functionalization, and templating strategies that guide the formation of desired architectures.

Comparative Analysis: Top-Down vs Bottom-Up

Top-down synthesis involves breaking down bulk materials into nanoscale structures through techniques like lithography and etching, offering precise control but limited scalability. Bottom-up synthesis assembles materials atom-by-atom or molecule-by-molecule using chemical vapor deposition or self-assembly, enabling defect-free nanostructures with higher scalability but less immediate size control. Comparative analysis reveals top-down approaches excel in pattern accuracy for microelectronics, whereas bottom-up methods outperform in producing complex, highly ordered nanomaterials for applications in catalysis and drug delivery.

Key Advantages of Top-Down Synthesis

Top-down synthesis offers precise control over nanoparticle size and morphology, enabling uniform and reproducible structures essential for advanced applications in electronics and catalysis. This approach facilitates scalability and integration into existing manufacturing processes, making it suitable for industrial production. The ability to start from bulk materials also reduces costs and simplifies purification compared to bottom-up methods.

Major Benefits of Bottom-Up Synthesis

Bottom-up synthesis offers precise control over molecular structure and composition, enabling the creation of complex nanomaterials with uniform size and properties. This method enhances reproducibility and scalability for advanced applications in electronics, catalysis, and drug delivery. Furthermore, bottom-up synthesis allows for tailored functionalization at the atomic level, improving material performance and integration in diverse technological fields.

Typical Applications in Nanomaterial Fabrication

Top-down synthesis methods, such as lithography and etching, are typically applied in fabricating nanoscale patterns and devices for electronics and photonics due to their precise control over size and shape. Bottom-up synthesis, including chemical vapor deposition and self-assembly, is widely used for producing nanoparticles, quantum dots, and nanowires with high purity and controlled crystallinity. Combining both approaches enables tailored nanomaterial architectures for applications in catalysis, drug delivery, and sensors.

Limitations and Challenges of Each Approach

Top-down synthesis often faces challenges in achieving precise control over nanoscale features, leading to limitations in uniformity and scalability due to reliance on lithographic and etching techniques. Bottom-up synthesis struggles with issues such as reproducibility and structural defects, as it relies on self-assembly and chemical reactions that are sensitive to environmental conditions and precursor purity. Both approaches encounter scalability hurdles, but bottom-up methods offer better atomic-level precision while top-down techniques provide easier integration with existing manufacturing processes.

Innovations and Future Trends in Synthesis Strategies

Top-down synthesis leverages precise control over material structure starting from bulk precursors, enabling innovations in nanoscale patterning and hierarchical architectures for electronics and catalysis. Bottom-up approaches emphasize molecular self-assembly and atom-by-atom construction, driving advancements in programmable materials and bio-inspired nanostructures with tailored functionalities. Future trends highlight hybrid strategies combining precision and scalability, integration of AI-driven design for predictive synthesis, and sustainable methodologies minimizing environmental impact in material production.

Selecting the Right Synthesis Method: Factors to Consider

Selecting the right synthesis method between top-down and bottom-up approaches depends on factors such as desired particle size, material properties, and application requirements. Top-down synthesis excels in producing uniform nanostructures from bulk materials, ideal for applications needing precise dimensions and scalability. Bottom-up synthesis allows for atomic-level control and the creation of novel nanomaterials with unique properties, suitable for catalysis, sensors, and advanced electronics.

Nanofabrication

Top-down synthesis in nanofabrication involves etching and patterning bulk materials to create nanoscale structures, while bottom-up synthesis assembles atoms or molecules to build nanostructures with precise control over composition and size.

Self-assembly

Top-down synthesis breaks bulk materials into nanoscale structures, while bottom-up synthesis uses molecular self-assembly to build nanostructures atom-by-atom or molecule-by-molecule with precise control over size and shape.

Mechanical milling

Mechanical milling in bottom-up synthesis enables precise nanoparticle formation by assembling atoms or molecules, contrasting with top-down approaches that rely on breaking down bulk materials into nanoscale particles.

Sol-gel processing

Top-down synthesis involves breaking down bulk materials into nanoscale structures, while bottom-up synthesis, exemplified by sol-gel processing, builds nanomaterials from molecular precursors through hydrolysis and condensation reactions forming a ceramic or glass network.

Lithography

Top-down lithography uses subtractive methods to pattern nanoscale features on substrates by etching bulk materials, while bottom-up synthesis assembles nanostructures atom-by-atom or molecule-by-molecule, enabling precise control of material composition and structure.

Chemical vapor deposition (CVD)

Chemical vapor deposition (CVD) exemplifies a bottom-up synthesis approach by enabling atomically precise growth of thin films and nanostructures through chemical reactions on substrate surfaces.

Atomic layer deposition (ALD)

Atomic layer deposition (ALD) exemplifies bottom-up synthesis by enabling precise, layer-by-layer atomic-scale film growth, contrasting with top-down methods that etch or pattern existing materials.

Ball milling

Ball milling, a top-down synthesis method, mechanically reduces bulk materials into nanoscale particles by repeated fracturing and cold welding, offering precise control over particle size compared to bottom-up chemical synthesis.

Molecular beam epitaxy

Molecular beam epitaxy exemplifies bottom-up synthesis by enabling atomic-level control in growing crystalline layers, contrasting with top-down approaches that rely on material removal from bulk substrates.

Seed-mediated growth

Seed-mediated growth in bottom-up synthesis enables precise control over nanoparticle size and morphology by using pre-formed seeds to direct material deposition.

Top-Down vs Bottom-Up Synthesis Infographic

njnir.com

njnir.com