Superhydrophobic coatings exhibit extreme water repellency by creating micro- and nanoscale surface roughness combined with low surface energy materials, effectively preventing water adhesion and promoting self-cleaning properties. Oleophobic coatings, on the other hand, are designed to resist oils and non-polar substances by minimizing surface energy to repel oily contaminants and reduce staining. Both coatings enhance material durability and cleanliness but target different types of liquids, making their selection crucial based on the application's exposure to water or oils.

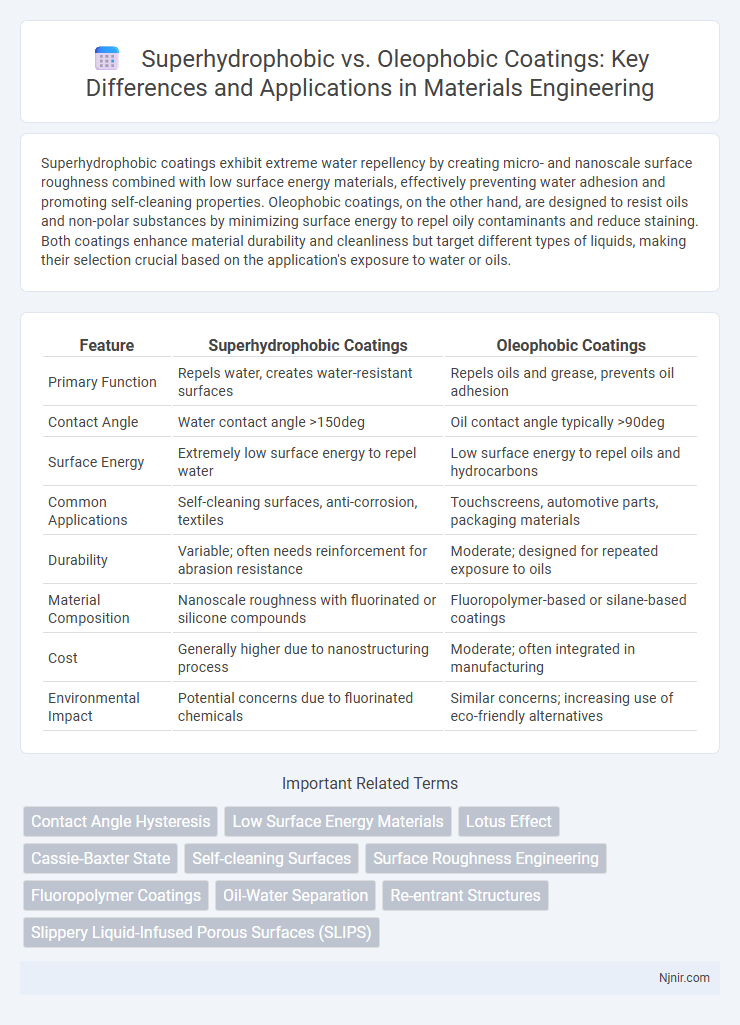

Table of Comparison

| Feature | Superhydrophobic Coatings | Oleophobic Coatings |

|---|---|---|

| Primary Function | Repels water, creates water-resistant surfaces | Repels oils and grease, prevents oil adhesion |

| Contact Angle | Water contact angle >150deg | Oil contact angle typically >90deg |

| Surface Energy | Extremely low surface energy to repel water | Low surface energy to repel oils and hydrocarbons |

| Common Applications | Self-cleaning surfaces, anti-corrosion, textiles | Touchscreens, automotive parts, packaging materials |

| Durability | Variable; often needs reinforcement for abrasion resistance | Moderate; designed for repeated exposure to oils |

| Material Composition | Nanoscale roughness with fluorinated or silicone compounds | Fluoropolymer-based or silane-based coatings |

| Cost | Generally higher due to nanostructuring process | Moderate; often integrated in manufacturing |

| Environmental Impact | Potential concerns due to fluorinated chemicals | Similar concerns; increasing use of eco-friendly alternatives |

Introduction to Surface Coatings in Materials Engineering

Superhydrophobic coatings create micro- and nanoscale surface textures combined with low surface energy materials to repel water droplets with contact angles exceeding 150deg, making surfaces highly water-resistant. Oleophobic coatings, designed to resist oils and grease, rely on fluoropolymer or silicone-based compounds that lower surface energy to prevent oil adhesion and staining on materials. Both coatings enhance material durability and functionality by controlling liquid-surface interactions, crucial in applications ranging from electronics and automotive components to textile engineering.

Defining Superhydrophobic and Oleophobic Coatings

Superhydrophobic coatings create surfaces with water contact angles exceeding 150deg, causing water droplets to bead and roll off, effectively repelling water and reducing surface wetting. Oleophobic coatings are specifically designed to resist oils and greasy substances, reducing fingerprint smudges and oil stains by minimizing adhesion of oils on surfaces. Both coatings utilize different chemical compositions and micro/nano-structured textures tailored to repel water or oil, serving distinct purposes in protective and functional surface applications.

Key Differences in Surface Chemistry

Superhydrophobic coatings create surfaces with micro- and nanoscale roughness combined with low surface energy materials, leading to extreme water repellency and contact angles above 150 degrees. Oleophobic coatings rely on fluorinated polymers or silica-based compounds to reduce surface energy specifically against oils, resulting in moderate repellency with contact angles typically ranging from 90 to 120 degrees. The key difference lies in the surface chemistry: superhydrophobic coatings emphasize hierarchical texture and very low surface free energy for water, while oleophobic coatings focus on molecular-scale chemical composition tailored for oil repellency.

Mechanisms of Water and Oil Repellency

Superhydrophobic coatings repel water primarily through a combination of micro- and nanoscale surface roughness and low surface energy materials, creating an air cushion that minimizes water contact and causes droplets to roll off easily. Oleophobic coatings, on the other hand, utilize fluorinated polymers with low surface energy to reduce oil adhesion by weak van der Waals interactions and create thin films that resist oil spreading. The distinct mechanisms hinge on the difference in surface tension; water's high surface tension is overcome by surface texture and energy, while the lower surface tension of oils demands chemical composition and molecular structure optimization for effective repellency.

Material Composition and Fabrication Techniques

Superhydrophobic coatings primarily consist of low surface energy materials such as fluorinated silanes combined with nanoscale roughness achieved through techniques like sol-gel processing, chemical vapor deposition, or electrospinning, enabling extreme water repellency. Oleophobic coatings typically incorporate fluoropolymer-based compounds and perfluorinated alkyl substances, fabricated via layer-by-layer assembly or plasma-enhanced chemical vapor deposition to resist oil and grease adhesion effectively. Material composition in both coatings relies heavily on fluorinated compounds, but fabrication techniques differ to optimize surface texture for either water or oil repellency.

Performance Evaluation and Testing Standards

Superhydrophobic coatings exhibit exceptional water repellency with water contact angles typically above 150deg, tested using standardized methods like ASTM D7334-08 for contact angle measurement. Oleophobic coatings are evaluated based on their ability to repel oils and reduce fingerprint adhesion, often assessed through tests such as the ASTM F728-88 oil repellency test. Performance evaluation metrics include durability under abrasion, resistance to chemical exposure, and retention of repellency, with industry standards guiding benchmark consistency for applications in electronics, textiles, and automotive surfaces.

Industrial and Commercial Applications

Superhydrophobic coatings exhibit extreme water repellency with contact angles above 150deg, making them ideal for preventing corrosion and ice formation on industrial machinery and commercial building surfaces. Oleophobic coatings resist oils and grease, enhancing the durability and cleanliness of electronic displays, food processing equipment, and automotive components by reducing smudge and residue buildup. Both coatings improve operational efficiency and maintenance cycles in industrial and commercial applications through tailored surface protection properties.

Durability and Environmental Stability

Superhydrophobic coatings exhibit superior water repellency and maintain durability under UV exposure and high humidity, making them highly resistant to environmental degradation. Oleophobic coatings, while effective against oils and fingerprints, generally demonstrate lower abrasion resistance and can degrade faster under prolonged exposure to oils and organic solvents. The enhanced environmental stability of superhydrophobic coatings results from their nanoscale surface textures combined with chemically robust materials, providing longer-lasting performance in harsh conditions.

Challenges in Large-Scale Implementation

Superhydrophobic coatings face challenges in large-scale implementation due to their complex micro- and nanoscale surface structures that are difficult to produce uniformly and maintain durability under mechanical stress. Oleophobic coatings struggle with chemical resistance and the ability to repel a wide range of oils, often requiring costly fluorinated compounds that raise environmental concerns. Both coatings must overcome issues related to scalability, cost-effectiveness, and long-term performance in diverse industrial applications.

Future Trends in Superhydrophobic and Oleophobic Technologies

Future trends in superhydrophobic and oleophobic coatings emphasize enhanced durability and multifunctionality to meet evolving industry demands. Advancements in nanotechnology enable the development of coatings with increased resistance to abrasion, UV exposure, and chemical degradation, expanding applications in automotive, electronics, and textiles. Integration of eco-friendly materials and scalable fabrication methods also drives innovation toward sustainable, high-performance protective surfaces.

Contact Angle Hysteresis

Superhydrophobic coatings exhibit low contact angle hysteresis typically below 10deg, enabling superior water repellency and self-cleaning properties compared to oleophobic coatings, which often have higher hysteresis values reducing their effectiveness against oil-based contaminants.

Low Surface Energy Materials

Superhydrophobic coatings utilize low surface energy materials such as fluorinated compounds and silicones to repel water effectively, while oleophobic coatings incorporate similar low surface energy substances like fluoropolymers to resist oils and greasy substances.

Lotus Effect

Superhydrophobic coatings leverage the Lotus Effect by mimicking the micro- and nanoscale surface structures of lotus leaves to repel water efficiently, whereas oleophobic coatings are designed primarily to resist oils and grease without the same textured surface.

Cassie-Baxter State

Superhydrophobic coatings achieve water repellency by maintaining the Cassie-Baxter state, where air pockets trapped beneath droplets reduce solid-liquid contact, whereas oleophobic coatings often struggle to sustain this state due to oil's lower surface tension.

Self-cleaning Surfaces

Superhydrophobic coatings create self-cleaning surfaces by repelling water and dirt through extreme water contact angles above 150deg, while oleophobic coatings primarily resist oils and fingerprints but offer less effective self-cleaning against water-based contaminants.

Surface Roughness Engineering

Surface roughness engineering in superhydrophobic coatings creates micro- and nanoscale textures that repel water by minimizing contact area, whereas oleophobic coatings utilize smoother, low-surface-energy materials to resist oils without relying heavily on surface texture.

Fluoropolymer Coatings

Fluoropolymer coatings provide superior superhydrophobic and oleophobic properties by creating low surface energy barriers that repel water and oils, enhancing durability and chemical resistance in various industrial applications.

Oil-Water Separation

Superhydrophobic coatings repel water with contact angles above 150deg, enabling efficient oil-water separation by allowing oil to pass through while blocking water, whereas oleophobic coatings resist oil adhesion but are primarily designed to prevent oil staining rather than separate oil from water.

Re-entrant Structures

Re-entrant structures in superhydrophobic coatings create enhanced water repellency by trapping air pockets, whereas oleophobic coatings utilize similar microtextures to repel oils but require different surface energy modifications due to lower liquid surface tension.

Slippery Liquid-Infused Porous Surfaces (SLIPS)

Slippery Liquid-Infused Porous Surfaces (SLIPS) outperform traditional superhydrophobic and oleophobic coatings by providing durable, self-healing, and low-adhesion properties through a lubricating liquid layer infused in micro/nanoporous substrates.

Superhydrophobic Coatings vs Oleophobic Coatings Infographic

njnir.com

njnir.com