Porous ceramics exhibit enhanced thermal insulation and reduced weight compared to dense ceramics, making them suitable for applications requiring energy efficiency and lightweight components. Dense ceramics provide superior mechanical strength and resistance to wear and corrosion, ideal for structural and high-stress environments. The choice between porous and dense ceramics depends on balancing thermal properties, mechanical demands, and specific application requirements in materials engineering.

Table of Comparison

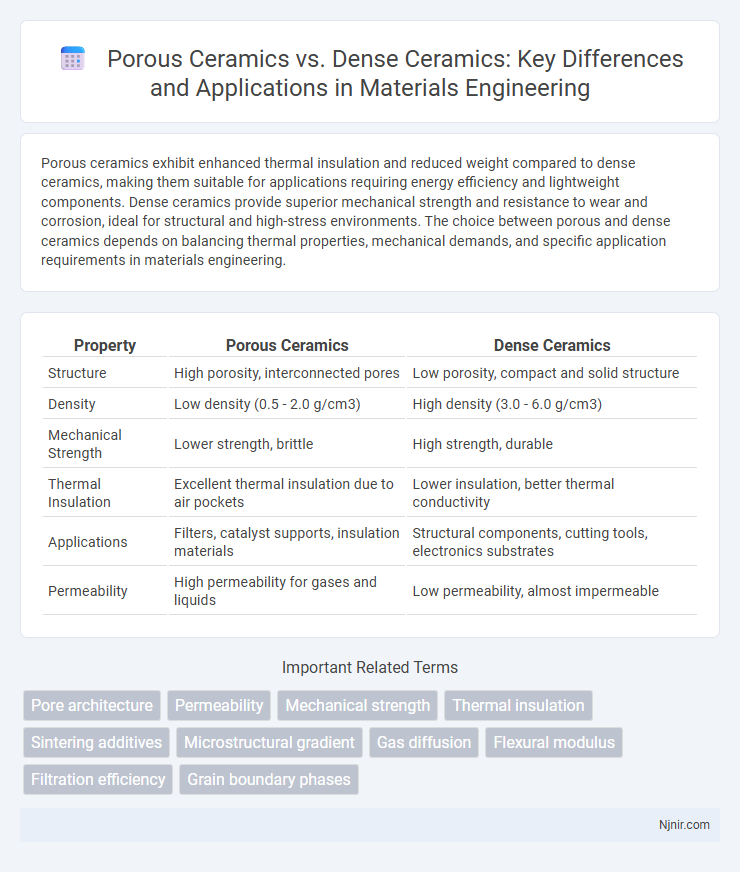

| Property | Porous Ceramics | Dense Ceramics |

|---|---|---|

| Structure | High porosity, interconnected pores | Low porosity, compact and solid structure |

| Density | Low density (0.5 - 2.0 g/cm3) | High density (3.0 - 6.0 g/cm3) |

| Mechanical Strength | Lower strength, brittle | High strength, durable |

| Thermal Insulation | Excellent thermal insulation due to air pockets | Lower insulation, better thermal conductivity |

| Applications | Filters, catalyst supports, insulation materials | Structural components, cutting tools, electronics substrates |

| Permeability | High permeability for gases and liquids | Low permeability, almost impermeable |

Introduction to Porous vs Dense Ceramics

Porous ceramics contain a network of interconnected voids that reduce density and enhance properties such as thermal insulation, filtration, and gas permeability, making them ideal for applications requiring lightweight and breathable materials. Dense ceramics exhibit minimal porosity, providing superior mechanical strength, hardness, and resistance to wear and corrosion, which suit them for structural components and high-stress environments. The distinct microstructural differences between porous and dense ceramics directly influence their thermal conductivity, electrical insulation, and chemical stability characteristics.

Microstructural Differences

Porous ceramics feature a network of interconnected pores, resulting in lower density and enhanced permeability, while dense ceramics exhibit a compact microstructure with minimal porosity, leading to higher mechanical strength and thermal conductivity. The pore size distribution, volume fraction, and connectivity in porous ceramics significantly influence properties such as insulation and filtration efficiency. In contrast, dense ceramics have tightly packed grains with strong grain boundary bonding, which contribute to their superior hardness and wear resistance.

Manufacturing Processes

Porous ceramics are typically manufactured using foaming agents, sacrificial templates, or freeze casting to create controlled pore structures, enabling lightweight and high surface area materials. Dense ceramics are produced through sintering and hot pressing methods that eliminate porosity, resulting in materials with high strength and low permeability. Precise control of temperature, pressure, and additives during these processes differentiates the microstructure and performance of porous versus dense ceramics.

Mechanical Properties Comparison

Porous ceramics exhibit lower mechanical strength and fracture toughness compared to dense ceramics due to their higher volume of voids, which act as stress concentrators. Dense ceramics provide superior hardness, compressive strength, and wear resistance, making them ideal for load-bearing applications. The reduced porosity in dense ceramics enhances their ability to withstand mechanical loads and resist crack propagation, resulting in improved durability.

Thermal Behavior and Insulation

Porous ceramics exhibit superior thermal insulation due to their low thermal conductivity, which arises from trapped air pockets within their microstructure that reduce heat transfer. In contrast, dense ceramics have higher thermal conductivity, allowing more efficient heat transfer but offering less insulation. The enhanced thermal behavior of porous ceramics makes them ideal for high-temperature insulation applications such as furnace linings and thermal barrier coatings.

Permeability and Porosity Levels

Porous ceramics exhibit high permeability and elevated porosity levels, allowing fluids and gases to pass through their interconnected pore structures, making them ideal for filtration and catalyst support applications. Dense ceramics, characterized by minimal porosity and negligible permeability, provide superior mechanical strength and are widely used in structural components requiring durability and resistance to wear. The contrast in porosity ranges typically spans from 10-50% in porous ceramics to less than 1% in dense ceramics, directly influencing their fluid transport and mechanical properties.

Applications in Industry

Porous ceramics are widely used in filtration, catalysis, and thermal insulation due to their high surface area and permeability, which enable gas and liquid flow while maintaining structural integrity. Dense ceramics find applications in cutting tools, electronics, and wear-resistant components because of their high strength, hardness, and electrical insulation properties. Industries such as chemical processing, aerospace, and electronics rely on the specific physical characteristics of both porous and dense ceramics to optimize performance and longevity in their respective applications.

Durability and Longevity

Porous ceramics exhibit lower durability due to their porous microstructure, which makes them more susceptible to mechanical wear and environmental degradation, significantly reducing their longevity in demanding applications. Dense ceramics offer superior durability and extended lifespan as their compact grain structure resists abrasion, chemical attack, and thermal shock more effectively. In industrial applications such as cutting tools, biomedical implants, and aerospace components, dense ceramics outlast porous variants, providing reliable performance under high-stress conditions.

Environmental Impact

Porous ceramics exhibit enhanced environmental benefits due to their ability to filter pollutants and support energy-efficient processes, reducing waste and emissions. Dense ceramics, while durable and long-lasting, generally require higher energy consumption during manufacturing, contributing to a larger carbon footprint. Choosing porous ceramics in applications like water treatment and air purification can significantly lower environmental impact by enabling sustainable resource management.

Future Trends in Ceramic Development

Future trends in ceramic development emphasize enhancing the functional properties of both porous and dense ceramics through nanotechnology and additive manufacturing. Porous ceramics are increasingly engineered for advanced filtration, catalysis, and biomedical scaffolds, leveraging controlled pore architecture to optimize performance. Dense ceramics see innovations in toughness and thermal stability driven by novel sintering techniques and composite formulations aimed at aerospace and electronic applications.

Pore architecture

Porous ceramics feature interconnected, controlled pore architectures enhancing filtration and insulation, whereas dense ceramics possess minimal porosity with tightly packed microstructures optimizing mechanical strength and wear resistance.

Permeability

Porous ceramics exhibit high permeability due to their interconnected pore structure, while dense ceramics have low permeability owing to their minimal porosity and compact microstructure.

Mechanical strength

Dense ceramics exhibit higher mechanical strength compared to porous ceramics due to their reduced porosity and enhanced structural integrity.

Thermal insulation

Porous ceramics provide superior thermal insulation compared to dense ceramics due to their low thermal conductivity and high air content within the microstructure.

Sintering additives

Sintering additives in porous ceramics enhance pore connectivity and mechanical strength, whereas in dense ceramics they promote grain boundary diffusion to achieve higher density and improved hardness.

Microstructural gradient

Porous ceramics exhibit a microstructural gradient characterized by interconnected pore networks that enhance permeability and reduce density, whereas dense ceramics possess uniform, compact microstructures that maximize mechanical strength and thermal conductivity.

Gas diffusion

Porous ceramics exhibit higher gas diffusion rates due to their interconnected pore structure, while dense ceramics have significantly lower gas permeability because of their compact, non-porous matrix.

Flexural modulus

Porous ceramics exhibit significantly lower flexural modulus compared to dense ceramics due to their reduced material density and increased internal voids.

Filtration efficiency

Porous ceramics exhibit higher filtration efficiency than dense ceramics due to their interconnected pore structure that enables superior particle capture and fluid flow control.

Grain boundary phases

Porous ceramics contain grain boundary phases with increased porosity that enhance permeability and thermal insulation, while dense ceramics have tightly bonded grain boundary phases that improve mechanical strength and wear resistance.

Porous ceramics vs Dense ceramics Infographic

njnir.com

njnir.com