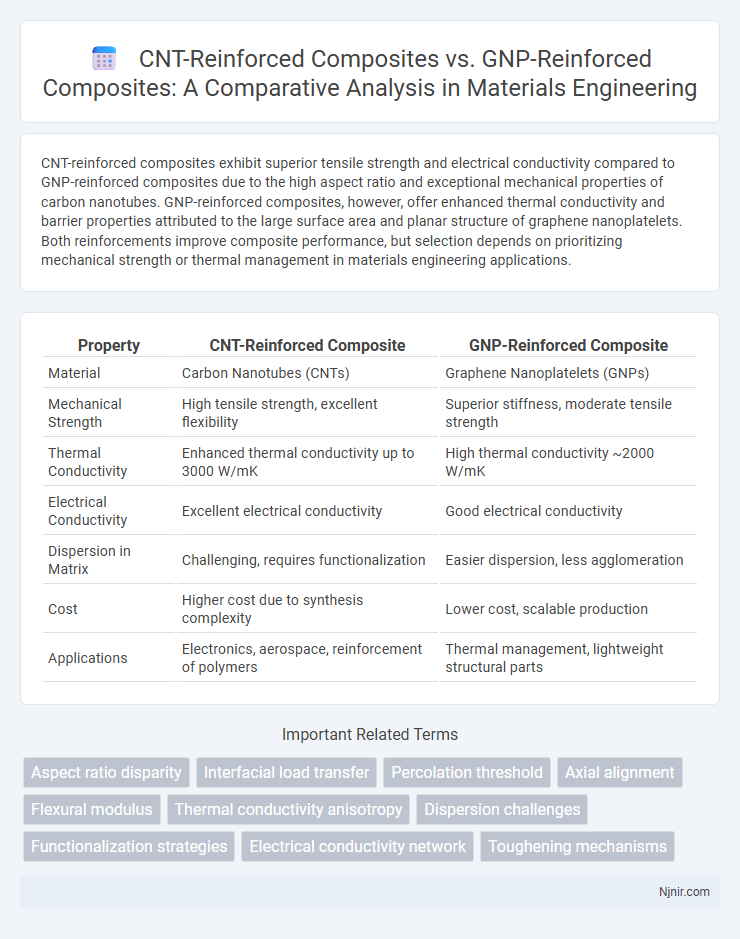

CNT-reinforced composites exhibit superior tensile strength and electrical conductivity compared to GNP-reinforced composites due to the high aspect ratio and exceptional mechanical properties of carbon nanotubes. GNP-reinforced composites, however, offer enhanced thermal conductivity and barrier properties attributed to the large surface area and planar structure of graphene nanoplatelets. Both reinforcements improve composite performance, but selection depends on prioritizing mechanical strength or thermal management in materials engineering applications.

Table of Comparison

| Property | CNT-Reinforced Composite | GNP-Reinforced Composite |

|---|---|---|

| Material | Carbon Nanotubes (CNTs) | Graphene Nanoplatelets (GNPs) |

| Mechanical Strength | High tensile strength, excellent flexibility | Superior stiffness, moderate tensile strength |

| Thermal Conductivity | Enhanced thermal conductivity up to 3000 W/mK | High thermal conductivity ~2000 W/mK |

| Electrical Conductivity | Excellent electrical conductivity | Good electrical conductivity |

| Dispersion in Matrix | Challenging, requires functionalization | Easier dispersion, less agglomeration |

| Cost | Higher cost due to synthesis complexity | Lower cost, scalable production |

| Applications | Electronics, aerospace, reinforcement of polymers | Thermal management, lightweight structural parts |

Introduction to Nanoreinforcements in Composites

Carbon nanotube (CNT)-reinforced composites exhibit exceptional mechanical strength, electrical conductivity, and thermal stability due to the unique one-dimensional structure and high aspect ratio of CNTs. Graphene nanoplatelet (GNP)-reinforced composites provide enhanced barrier properties, improved thermal conductivity, and excellent load transfer efficiency derived from the two-dimensional morphology and large surface area of GNPs. Both nanoreinforcements significantly enhance composite performance by tailoring interfacial interactions and multifunctional characteristics, crucial for advanced aerospace, automotive, and electronic applications.

Structural Properties of CNT-Reinforced vs GNP-Reinforced Composites

CNT-reinforced composites exhibit superior tensile strength and enhanced fracture toughness compared to GNP-reinforced composites due to the high aspect ratio and exceptional load transfer capability of carbon nanotubes. GNP-reinforced composites, however, demonstrate improved in-plane stiffness and electrical conductivity attributable to the graphene nanoplatelets' layered structure and larger surface area. Both reinforcements enhance mechanical properties, but CNTs excel in reinforcing multidirectional loads while GNPs optimize planar structural attributes.

Mechanical Performance Comparison

CNT-reinforced composites exhibit superior tensile strength and Young's modulus compared to GNP-reinforced composites due to the high aspect ratio and exceptional mechanical properties of carbon nanotubes. GNP-reinforced composites demonstrate enhanced fracture toughness and in-plane stiffness, attributed to the planar structure and effective load transfer capabilities of graphene nanoplatelets. Both reinforcements improve mechanical performance, but CNTs excel in strength and stiffness, while GNPs provide better toughness and impact resistance.

Thermal Conductivity Enhancement

CNT-reinforced composites exhibit superior thermal conductivity enhancement compared to GNP-reinforced composites due to the one-dimensional structure of carbon nanotubes, which facilitates efficient phonon transport along their length. GNPs, with their two-dimensional platelet structure, provide high in-plane thermal conductivity but face limitations in through-thickness heat transfer due to interlayer thermal resistance. The percolation network formed by CNTs enables continuous heat conduction pathways, resulting in higher overall thermal conductivity improvements in polymer matrices.

Electrical Conductivity Improvements

CNT-reinforced composites exhibit significantly enhanced electrical conductivity due to the one-dimensional structure of carbon nanotubes that facilitates efficient electron transport along their length. GNP-reinforced composites improve conductivity by forming interconnected two-dimensional networks that provide extensive surface contact and electron pathways. The intrinsic high aspect ratio of CNTs generally leads to lower electrical percolation thresholds compared to GNPs, resulting in superior conductivity improvements at lower filler concentrations.

Dispersion Challenges and Processing Techniques

CNT-reinforced composites face significant dispersion challenges due to the high aspect ratio and strong van der Waals forces causing nanotube agglomeration, requiring advanced techniques like ultrasonication, high-shear mixing, and surface functionalization to achieve uniform distribution. In contrast, GNP-reinforced composites, while also prone to stacking and restacking from p-p interactions, benefit from solvent-assisted exfoliation and mechanical stirring methods for better particle separation. Processing techniques such as solution mixing for CNTs and melt blending for GNPs are optimized differently to address their unique dispersion behaviors, directly impacting the mechanical and electrical performance of the composites.

Interfacial Bonding Mechanisms

CNT-reinforced composites exhibit strong interfacial bonding primarily due to the high aspect ratio and tubular structure of carbon nanotubes, which facilitate efficient load transfer through mechanical interlocking and van der Waals forces. GNP-reinforced composites rely on planar graphene nanoplatelets that provide extensive surface area for p-p stacking interactions and covalent bonding opportunities when functionalized. The distinct dimensionality of CNTs and GNPs influences their stress distribution efficiency, with CNTs offering superior fiber pull-out resistance and GNPs enhancing matrix stiffness and toughness via platelet alignment.

Cost and Scalability Considerations

CNT-reinforced composites typically incur higher production costs due to complex synthesis processes and limited scalability in large-scale manufacturing, which constrain widespread industrial adoption. GNP-reinforced composites offer more cost-effective solutions with greater scalability owing to abundant graphite sources and simpler exfoliation techniques, enabling easier integration into mass production. Balancing performance advantages against economic factors is crucial when selecting between CNT and GNP reinforcements for composite material applications.

Applications in Advanced Engineering Fields

CNT-reinforced composites exhibit exceptional electrical conductivity and mechanical strength, making them ideal for aerospace, flexible electronics, and high-performance structural components. GNP-reinforced composites offer superior thermal conductivity and enhanced wear resistance, widely applied in automotive heat sinks, electronic packaging, and thermal interface materials. Both materials advance fields requiring lightweight, durable, and multifunctional materials, but CNT composites dominate in nanoelectronics while GNP composites excel in thermal management applications.

Future Trends and Research Directions

Future trends in CNT-reinforced composites focus on enhancing electrical conductivity and mechanical toughness through hybridization with graphene nanoplatelets (GNPs) and optimizing dispersion techniques. Research directions emphasize scalable manufacturing processes and multifunctional properties for applications in aerospace, electronics, and energy storage. Advances in computational modeling and machine learning are also driving the design of tailored nanocomposites with improved interface engineering and environmental sustainability.

Aspect ratio disparity

CNT-reinforced composites exhibit significantly higher aspect ratios than GNP-reinforced composites, leading to enhanced mechanical strength and electrical conductivity in CNT-based materials.

Interfacial load transfer

CNT-reinforced composites exhibit superior interfacial load transfer due to their high aspect ratio and strong van der Waals interactions compared to GNP-reinforced composites, enhancing mechanical performance and stress distribution.

Percolation threshold

CNT-reinforced composites exhibit a lower percolation threshold than GNP-reinforced composites due to the higher aspect ratio and superior electrical conductivity of carbon nanotubes.

Axial alignment

Axial alignment in CNT-reinforced composites significantly enhances tensile strength and electrical conductivity compared to GNP-reinforced composites due to the one-dimensional morphology and superior aspect ratio of carbon nanotubes.

Flexural modulus

CNT-reinforced composites exhibit higher flexural modulus compared to GNP-reinforced composites due to the superior intrinsic strength and aspect ratio of carbon nanotubes.

Thermal conductivity anisotropy

CNT-reinforced composites exhibit higher thermal conductivity anisotropy compared to GNP-reinforced composites due to the one-dimensional structure of CNTs enabling directional heat transfer along their length.

Dispersion challenges

CNT-reinforced composites face greater dispersion challenges due to the high aspect ratio and strong van der Waals forces of carbon nanotubes compared to GNP-reinforced composites, which typically exhibit better dispersion due to the planar structure of graphene nanoplatelets.

Functionalization strategies

Functionalization strategies for CNT-reinforced composites primarily involve covalent bonding and non-covalent interactions to enhance dispersion and interfacial bonding, while GNP-reinforced composites emphasize surface oxidation and linker molecules to improve compatibility and mechanical performance.

Electrical conductivity network

CNT-reinforced composites exhibit superior electrical conductivity networks compared to GNP-reinforced composites due to the one-dimensional tubular structure of carbon nanotubes facilitating more effective electron transport pathways.

Toughening mechanisms

CNT-reinforced composites enhance toughness primarily through crack bridging, pull-out, and energy dissipation mechanisms, while GNP-reinforced composites improve toughness via crack deflection, crack branching, and interfacial debonding.

CNT-reinforced composite vs GNP-reinforced composite Infographic

njnir.com

njnir.com