Martensite is a hard, brittle phase formed by rapid cooling of austenite, characterized by a distorted body-centered tetragonal structure, which significantly increases steel's strength and hardness. Austenite, with its face-centered cubic structure, is stable at high temperatures and provides ductility and toughness, allowing for easier shaping and forming of steel. Controlling the transformation between austenite and martensite is crucial in heat treatment processes to optimize mechanical properties for various engineering applications.

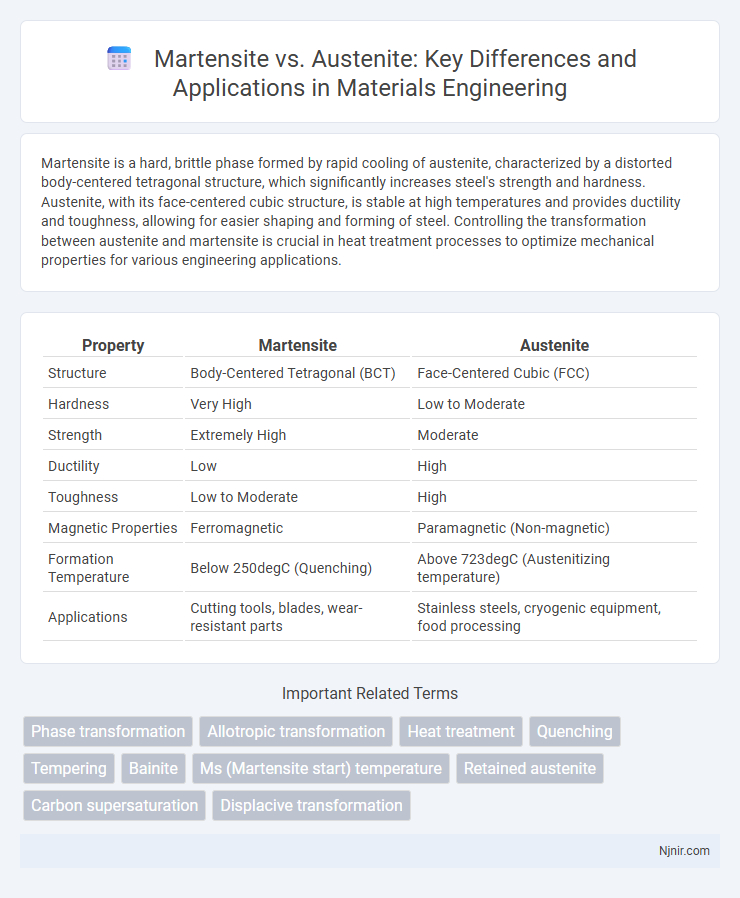

Table of Comparison

| Property | Martensite | Austenite |

|---|---|---|

| Structure | Body-Centered Tetragonal (BCT) | Face-Centered Cubic (FCC) |

| Hardness | Very High | Low to Moderate |

| Strength | Extremely High | Moderate |

| Ductility | Low | High |

| Toughness | Low to Moderate | High |

| Magnetic Properties | Ferromagnetic | Paramagnetic (Non-magnetic) |

| Formation Temperature | Below 250degC (Quenching) | Above 723degC (Austenitizing temperature) |

| Applications | Cutting tools, blades, wear-resistant parts | Stainless steels, cryogenic equipment, food processing |

Introduction to Martensite and Austenite

Martensite is a hard, brittle microstructure formed in steel when austenite is rapidly cooled or quenched, characterized by its tetragonal crystal structure and high dislocation density. Austenite, also known as gamma iron, is a face-centered cubic (FCC) phase stable at high temperatures, known for its ductility and ability to dissolve more carbon than ferrite. The transformation from austenite to martensite is diffusionless, driven by shear, and critically influences the hardness and mechanical properties of steel alloys.

Crystal Structure Comparison

Martensite exhibits a body-centered tetragonal (BCT) crystal structure characterized by a distorted lattice resulting from rapid quenching, which imparts high hardness and strength. Austenite possesses a face-centered cubic (FCC) crystal structure that provides greater ductility and toughness due to its symmetrical atomic arrangement. The transformation between austenite and martensite involves a diffusionless shear process, drastically altering mechanical properties through structural reconfiguration.

Formation Mechanisms

Martensite forms through a diffusionless, shear-dominant transformation where the face-centered cubic (FCC) austenite rapidly changes into a body-centered tetragonal (BCT) phase, resulting from rapid cooling or quenching. Austenite stabilizes at high temperatures with a face-centered cubic (FCC) crystal structure, maintained by slow cooling that allows carbon atoms to diffuse uniformly. The key difference in formation mechanisms lies in martensite's non-diffusional, shear-induced transformation compared to austenite's diffusional, thermodynamically stable phase at elevated temperatures.

Mechanical Properties

Martensite exhibits significantly higher hardness and tensile strength due to its body-centered tetragonal crystal structure, making it ideal for wear-resistant applications. Austenite, characterized by a face-centered cubic structure, provides superior toughness and ductility, which enhances its ability to absorb energy without fracturing. The contrasting mechanical properties of martensite and austenite influence their use in steels where strength-to-ductility balance is critical.

Thermal Stability and Transformation

Martensite exhibits low thermal stability due to its supersaturated, distorted lattice structure, which transforms into austenite upon heating above the critical temperature (around 723degC for steel). Austenite, characterized by a face-centered cubic (FCC) structure, is thermally stable at high temperatures and transforms to martensite during rapid cooling or quenching. The martensitic transformation is diffusionless and occurs almost instantaneously, whereas austenite remains stable until it cools below the martensite start (Ms) temperature.

Magnetic Properties

Martensite exhibits strong ferromagnetic properties due to its body-centered tetragonal (BCT) structure, resulting in higher magnetic saturation and coercivity compared to austenite. Austenite, with its face-centered cubic (FCC) structure, is generally paramagnetic or weakly ferromagnetic, causing reduced magnetic susceptibility and lower magnetic permeability. These differences influence the selection of steel types in applications requiring specific magnetic behaviors, such as transformers or magnetic sensors.

Role in Steel Heat Treatment

Martensite forms during rapid quenching of steel and contributes to high hardness and strength due to its distorted body-centered tetragonal structure. Austenite, stable at high temperatures, acts as the parent phase in heat treatment, allowing carbon to dissolve and redistribute for desired microstructural changes. Controlling the transformation between austenite and martensite is critical for tailoring mechanical properties in steel through processes like quenching and tempering.

Microstructural Characteristics

Martensite exhibits a highly distorted, body-centered tetragonal (BCT) crystal structure formed by rapid quenching of austenite, resulting in a hard and brittle microstructure with needle-like laths or plates. Austenite, or gamma iron, has a face-centered cubic (FCC) crystal structure, which provides greater ductility and toughness at elevated temperatures. The transformation from austenite to martensite involves diffusionless shear, producing internal stresses and dislocations that significantly enhance strength but reduce ductility.

Industrial Applications

Martensite's high hardness and strength make it ideal for cutting tools, wear-resistant components, and structural parts in aerospace and automotive industries. Austenite, characterized by its excellent corrosion resistance and toughness, is extensively used in stainless steel production for chemical processing equipment, food industry machinery, and medical implants. The differential thermal properties of martensite and austenite enable heat treatment processes that optimize mechanical performance for specific industrial applications.

Future Research Directions

Future research on martensite versus austenite will prioritize the development of advanced characterization techniques to better understand phase transformation mechanisms at the nanoscale. Emphasis will be placed on designing novel alloy compositions and heat treatment processes that optimize mechanical properties and corrosion resistance by controlling the balance between martensitic and austenitic phases. Integrating computational materials science with experimental approaches will accelerate the discovery of high-performance steels and shape memory alloys with tailored microstructures for aerospace and biomedical applications.

Phase transformation

Martensite forms through a rapid, diffusionless phase transformation from austenite, resulting in a hard, brittle microstructure, while austenite is a face-centered cubic phase stable at high temperatures and transforms to martensite upon rapid cooling.

Allotropic transformation

Martensite forms from a diffusionless allotropic transformation of austenite, rapidly changing from a face-centered cubic (FCC) structure to a body-centered tetragonal (BCT) structure during rapid cooling.

Heat treatment

Martensite forms through rapid quenching of Austenite during heat treatment, resulting in a hard and brittle microstructure, whereas controlled cooling of Austenite produces softer, more ductile phases like pearlite or bainite.

Quenching

Quenching transforms austenite into martensite by rapidly cooling steel, resulting in a hard, brittle microstructure compared to the softer, ductile austenite phase.

Tempering

Tempering transforms brittle martensite into tempered martensite by relieving internal stresses and enhancing toughness, whereas austenite softens during tempering and stabilizes the microstructure.

Bainite

Bainite is a microstructure formed at intermediate temperatures between Martensite and Austenite, offering a balance of strength and toughness by combining fine, needle-like carbides within a ferrite matrix.

Ms (Martensite start) temperature

Ms (Martensite start) temperature marks the critical point at which austenite begins transforming into martensite during cooling in steel alloys.

Retained austenite

Retained austenite in martensitic steels significantly influences mechanical properties by enhancing toughness but can reduce hardness and dimensional stability.

Carbon supersaturation

Martensite features a body-centered tetragonal structure characterized by carbon supersaturation that significantly enhances hardness, whereas austenite has a face-centered cubic structure with carbon atoms dissolved in interstitial sites, resulting in lower carbon supersaturation and greater ductility.

Displacive transformation

Martensite forms through a rapid, displacive transformation characterized by a shear-dominant, diffusionless lattice distortion from the face-centered cubic structure of Austenite to a body-centered tetragonal crystal.

Martensite vs Austenite Infographic

njnir.com

njnir.com