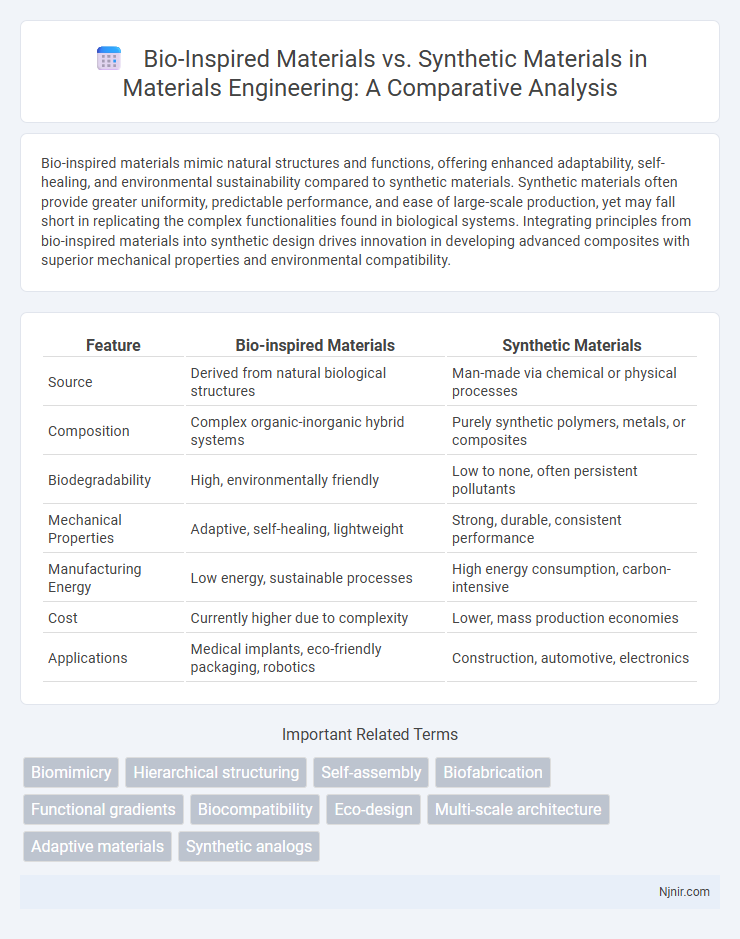

Bio-inspired materials mimic natural structures and functions, offering enhanced adaptability, self-healing, and environmental sustainability compared to synthetic materials. Synthetic materials often provide greater uniformity, predictable performance, and ease of large-scale production, yet may fall short in replicating the complex functionalities found in biological systems. Integrating principles from bio-inspired materials into synthetic design drives innovation in developing advanced composites with superior mechanical properties and environmental compatibility.

Table of Comparison

| Feature | Bio-inspired Materials | Synthetic Materials |

|---|---|---|

| Source | Derived from natural biological structures | Man-made via chemical or physical processes |

| Composition | Complex organic-inorganic hybrid systems | Purely synthetic polymers, metals, or composites |

| Biodegradability | High, environmentally friendly | Low to none, often persistent pollutants |

| Mechanical Properties | Adaptive, self-healing, lightweight | Strong, durable, consistent performance |

| Manufacturing Energy | Low energy, sustainable processes | High energy consumption, carbon-intensive |

| Cost | Currently higher due to complexity | Lower, mass production economies |

| Applications | Medical implants, eco-friendly packaging, robotics | Construction, automotive, electronics |

Introduction to Bio-Inspired and Synthetic Materials

Bio-inspired materials mimic natural structures and functions to achieve enhanced durability, adaptability, and efficiency, often replicating biological processes such as self-healing or energy conversion. Synthetic materials, engineered through chemical synthesis and manufacturing, offer precise control over composition and properties, enabling tailored performance for specific applications like aerospace or electronics. The convergence of bio-inspired and synthetic materials drives innovation in sustainable and high-performance solutions by combining nature's principles with advanced technology.

Key Principles of Bio-Inspired Material Design

Bio-inspired material design leverages natural structures, such as hierarchical organization and self-healing capabilities, to enhance performance and sustainability. Key principles include mimicking biological functions like adaptability, efficiency, and resilience found in organisms like nacre and spider silk. This approach contrasts with synthetic materials, which often prioritize strength and durability but may lack the multifunctional and eco-friendly properties inherent in bio-inspired designs.

Common Types of Synthetic Materials in Use

Common types of synthetic materials include polymers such as polyethylene, polypropylene, and polyvinyl chloride (PVC), widely used for packaging, construction, and automotive components. Synthetic fibers like nylon, polyester, and acrylic dominate textile manufacturing due to their durability and versatility. Additionally, engineered composites combining synthetic resins with reinforcing fibers extend applications in aerospace, sports equipment, and medical devices, offering tailored mechanical properties unmatched by natural materials.

Comparative Mechanical Properties

Bio-inspired materials exhibit remarkable toughness, flexibility, and self-healing capabilities due to their hierarchical microstructures and organic-inorganic hybrid compositions that mimic natural systems like nacre and spider silk. Synthetic materials, while often superior in uniformity and strength under controlled conditions, typically lack the intricate energy dissipation mechanisms found in bio-inspired counterparts, resulting in lower impact resistance and durability. Comparative studies highlight that bio-inspired materials can outperform synthetics in applications requiring lightweight, resilient structures with adaptive mechanical responses.

Sustainability and Environmental Impact

Bio-inspired materials mimic natural processes and structures, leading to enhanced biodegradability and reduced reliance on non-renewable resources, which significantly lowers environmental impact. Synthetic materials often involve energy-intensive production and generate persistent waste, contributing to pollution and resource depletion. Innovations in bio-inspired materials prioritize circular economy principles, promoting sustainability through renewable sourcing and end-of-life recyclability.

Innovations Driven by Bio-Mimicry

Bio-inspired materials leverage natural structures and processes to create innovative solutions in areas such as self-healing surfaces, adaptive camouflage, and energy-efficient designs, outperforming traditional synthetic materials in sustainability and functionality. Advances in bio-mimicry have led to the development of materials like spider silk-inspired polymers and lotus leaf-like coatings that exhibit superior strength and water repellency compared to conventional synthetics. These innovations drive transformative applications in aerospace, medicine, and environmental technologies, emphasizing renewable resources and reduced ecological impact.

Fabrication Techniques and Scalability

Bio-inspired materials utilize advanced fabrication techniques such as self-assembly, biomimetic mineralization, and hierarchical structuring, enabling precise control over nanoscale features and functional properties. Synthetic materials rely heavily on conventional manufacturing processes like chemical vapor deposition, electrospinning, and 3D printing, which offer higher throughput but often less complexity at micro- and nano-scales. Scalability of bio-inspired materials remains a challenge due to intricate fabrication steps and cost constraints, whereas synthetic materials benefit from established industrial-scale production methods, facilitating broader commercial applications.

Application Areas: Medical, Aerospace, and Beyond

Bio-inspired materials exhibit superior biocompatibility and self-healing properties, making them ideal for medical implants, tissue engineering, and drug delivery systems. Synthetic materials dominate aerospace applications with their high strength-to-weight ratios, thermal resistance, and customizability essential for airframes, propulsion systems, and thermal protection. Beyond these areas, bio-inspired designs influence robotics and environmental sensing, while synthetic composites advance electronics and automotive industries through tailored conductivity and durability.

Challenges in Integrating Bio-Inspired and Synthetic Approaches

Integrating bio-inspired materials with synthetic materials presents challenges including differences in mechanical properties, scalability, and compatibility at the molecular level. Achieving seamless interface bonding requires advanced techniques like biomimetic surface modification and nanostructuring. Addressing issues such as biocompatibility, environmental stability, and cost-effective production remains critical for successful hybrid material development.

Future Trends in Material Science Development

Future trends in material science development highlight the increasing integration of bio-inspired materials, which offer sustainable, adaptive, and self-healing properties derived from natural systems, contrasting with traditional synthetic materials that prioritize scalability and consistency. Advances in biomimicry and nanotechnology are accelerating the design of materials that mimic biological structures at the molecular level, leading to innovations in lightweight composites, energy-efficient catalysts, and responsive surfaces. Emerging applications in aerospace, healthcare, and environmental technology drive the shift toward hybrid materials that combine the best attributes of bio-inspired and synthetic components for enhanced performance and reduced ecological impact.

Biomimicry

Bio-inspired materials leverage biomimicry to replicate natural structures and functions, offering sustainable, adaptive properties often unmatched by conventional synthetic materials.

Hierarchical structuring

Bio-inspired materials exhibit hierarchical structuring that mimics natural systems, enhancing mechanical strength and multifunctionality compared to the often uniform architecture of synthetic materials.

Self-assembly

Bio-inspired materials utilize natural self-assembly processes mimicking biological systems to create complex, adaptive structures, whereas synthetic materials rely on controlled chemical synthesis and external manipulation for self-assembly, often lacking the dynamic adaptability of their bio-inspired counterparts.

Biofabrication

Biofabrication leverages bio-inspired materials to create sustainable, biodegradable structures that mimic natural processes, outperforming traditional synthetic materials in environmental impact and functionality.

Functional gradients

Bio-inspired materials exhibit superior functional gradients by mimicking natural property variations, enabling enhanced adaptability and performance compared to uniform synthetic materials.

Biocompatibility

Bio-inspired materials exhibit superior biocompatibility compared to synthetic materials due to their natural molecular structures that reduce immune responses and promote cellular integration.

Eco-design

Bio-inspired materials enhance eco-design by mimicking natural processes to reduce environmental impact, whereas synthetic materials often rely on non-renewable resources and generate higher waste.

Multi-scale architecture

Bio-inspired materials with multi-scale architecture mimic natural hierarchical structures to achieve superior mechanical properties and functionality compared to uniform synthetic materials.

Adaptive materials

Bio-inspired adaptive materials mimic natural responsiveness through self-healing and environmental sensing, whereas synthetic adaptive materials rely on engineered stimuli-responsive polymers and shape-memory alloys for dynamic functionality.

Synthetic analogs

Synthetic analogs of bio-inspired materials replicate natural structures using engineered polymers and composites, offering enhanced durability, tunable properties, and scalable production for advanced applications in medicine, robotics, and environmental sustainability.

Bio-inspired materials vs Synthetic materials Infographic

njnir.com

njnir.com