Surface roughness refers to the fine, closely spaced irregularities on a machined surface, typically caused by the cutting process and tool marks. Surface waviness involves the more widely spaced deviations from the nominal surface profile, often resulting from machine tool vibrations or deflections. Controlling both factors is essential for ensuring proper fit, function, and longevity of mechanical components.

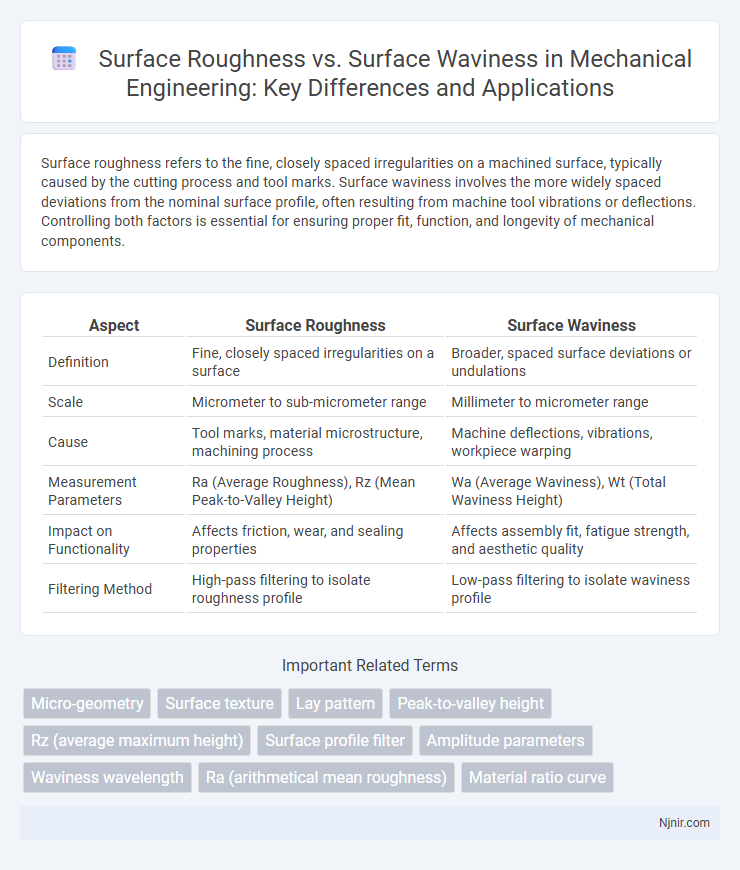

Table of Comparison

| Aspect | Surface Roughness | Surface Waviness |

|---|---|---|

| Definition | Fine, closely spaced irregularities on a surface | Broader, spaced surface deviations or undulations |

| Scale | Micrometer to sub-micrometer range | Millimeter to micrometer range |

| Cause | Tool marks, material microstructure, machining process | Machine deflections, vibrations, workpiece warping |

| Measurement Parameters | Ra (Average Roughness), Rz (Mean Peak-to-Valley Height) | Wa (Average Waviness), Wt (Total Waviness Height) |

| Impact on Functionality | Affects friction, wear, and sealing properties | Affects assembly fit, fatigue strength, and aesthetic quality |

| Filtering Method | High-pass filtering to isolate roughness profile | Low-pass filtering to isolate waviness profile |

Introduction to Surface Texture in Mechanical Engineering

Surface roughness refers to the fine irregularities on a machined surface characterized by small-scale variations in height, typically measured in micrometers. Surface waviness represents larger-scale deviations or undulations on the surface, often caused by machine tool vibrations or deflections during manufacturing processes. Understanding the distinction between surface roughness and waviness is critical in mechanical engineering for evaluating functional performance, wear resistance, and fatigue strength of components.

Defining Surface Roughness and Surface Waviness

Surface roughness refers to the fine, closely spaced irregularities on a surface generated by the machining process, characterized by high-frequency, low-amplitude deviations from the nominal surface. Surface waviness consists of more widely spaced, low-frequency variations in the surface profile caused by factors such as machine vibration, tool deflection, or warping during manufacturing. Both surface roughness and waviness significantly affect the functional performance and aesthetics of a component, with roughness often influencing friction and wear, while waviness impacts fit and sealing properties.

Key Differences between Surface Roughness and Waviness

Surface roughness refers to the fine, closely spaced surface irregularities typically resulting from the machining process, with measurements often in micrometers (um) focusing on high-frequency, small-scale deviations. Surface waviness describes the more widely spaced, low-frequency surface irregularities caused by factors such as machine deflection or vibration, with wavelengths significantly longer than those of roughness. Key differences lie in the scale, origin, and measurement methods: roughness captures microscopic texture, while waviness addresses larger, periodic deviations.

Measurement Techniques for Surface Roughness

Surface roughness refers to the fine, closely spaced irregularities on a machined surface, typically measured using profilometers that trace the surface and record deviations at a micrometer scale. Common measurement techniques for surface roughness include contact stylus profilometry, where a diamond-tipped stylus moves across the surface, and non-contact optical methods such as white light interferometry and laser scanning confocal microscopy, which provide high-resolution, three-dimensional surface topography without physical contact. Surface waviness involves larger-scale, more widely spaced deviations and requires different measurement approaches focused on filtering out roughness components to isolate the waviness profile.

Tools and Methods for Assessing Surface Waviness

Surface waviness is typically assessed using profilometers equipped with high-pass filters that isolate waviness from roughness by removing short-wavelength surface variations. Tools like contact stylus profilometers and non-contact optical profilometers measure waviness parameters such as Wt (total waviness height) and Wa (average waviness), providing critical data for surface integrity analysis. Advanced methods, including laser interferometry and coherence scanning interferometry, offer high-resolution waviness measurement essential for precision engineering and quality control.

Causes and Sources of Surface Roughness

Surface roughness originates from machining tool marks, material deformation, and vibrations during cutting processes, contributing to microscopic irregularities on the surface. In contrast, surface waviness is caused by factors such as machine tool and workpiece deflections, misalignment, and thermal distortions, resulting in larger-scale undulations. Key sources of surface roughness include tool geometry, feed rate, cutting speed, and material properties that directly affect the micro-scale texture of the finished component.

Origins and Influencing Factors of Surface Waviness

Surface waviness originates from larger-scale deviations on a material's surface caused by machine tool vibrations, deflections, and feed rate variations during manufacturing processes. Influencing factors include the rigidity of the machining setup, the condition of cutting tools, and operational parameters such as spindle speed and feed rate. Unlike surface roughness, which is affected by micro-scale irregularities from machining marks, waviness reflects periodic geometric distortions resulting from mechanical or thermal instabilities.

Effects of Surface Roughness and Waviness on Component Performance

Surface roughness influences friction, wear, and lubrication retention on component surfaces, directly affecting the lifespan and efficiency of mechanical parts. Surface waviness impacts the overall fit and alignment of assemblies, leading to potential vibration, noise, and premature fatigue failure. Optimizing both roughness and waviness parameters ensures superior surface integrity, enhances seal effectiveness, and improves the reliability of critical components in high-precision applications.

Standards and Symbols for Surface Texture Specification

Surface roughness and surface waviness are critical parameters defined in ISO 1302 and ASME B46.1 standards for surface texture specification, where roughness refers to fine irregularities on the surface and waviness denotes more widely spaced variations. Roughness is commonly represented by symbols such as Ra (average roughness), Rz (mean peak-to-valley height), and Wa (waviness average) is used specifically for waviness features. Correct application of these standardized symbols ensures accurate communication and quality control in engineering and manufacturing processes.

Practical Applications: Controlling Surface Roughness and Waviness

Surface roughness and waviness significantly influence product performance in manufacturing and engineering, where precise control is essential for functionality and durability. Surface roughness, characterized by fine irregularities, is critical in applications such as sealing surfaces and bearing contacts to minimize friction and wear. Surface waviness, defined by broader surface deviations, impacts assembly alignment and vibration resistance, necessitating distinct measurement and machining strategies to optimize product quality.

Micro-geometry

Surface roughness characterizes fine micro-geometric irregularities on a surface, while surface waviness refers to larger-scale undulations influencing the overall micro-geometry profile.

Surface texture

Surface roughness refers to the fine, closely spaced irregularities on a surface, while surface waviness describes the broader, more widely spaced deviations in surface texture that affect functional performance.

Lay pattern

Surface roughness measures fine surface irregularities, while surface waviness captures broader, more widely spaced deviations; both are influenced by the lay pattern, which defines the predominant direction of surface texture aligned with machining processes.

Peak-to-valley height

Surface roughness measures fine surface irregularities with a typically lower peak-to-valley height, while surface waviness represents broader, more widely spaced deviations with significantly higher peak-to-valley heights affecting overall surface texture.

Rz (average maximum height)

Surface roughness Rz measures the average maximum height of micro-scale surface irregularities, while surface waviness captures larger-scale undulations distinct from roughness features.

Surface profile filter

Surface roughness represents fine surface irregularities filtered out by a high-pass surface profile filter, while surface waviness indicates broader undulations isolated by a low-pass filter in surface metrology.

Amplitude parameters

Surface roughness amplitude parameters, such as Ra and Rz, measure small-scale surface texture variations, while surface waviness amplitude parameters quantify larger-scale, more widely spaced deviations like Wt and Wz.

Waviness wavelength

Surface waviness features longer wavelengths typically ranging from 0.25 mm to several millimeters, distinguishing it from the finer, shorter wavelengths of surface roughness that measure microscopic texture variations.

Ra (arithmetical mean roughness)

Surface roughness, measured by Ra (arithmetical mean roughness), quantifies fine surface irregularities, while surface waviness represents broader, more widely spaced deviations.

Material ratio curve

The material ratio curve differentiates surface roughness from waviness by quantifying the distribution of peaks and valleys at varying depths, highlighting micro-texture irregularities versus broader surface deviations.

Surface roughness vs surface waviness Infographic

njnir.com

njnir.com