Magnetic bearings offer frictionless operation and reduced wear by levitating the rotor using electromagnetic forces, resulting in higher efficiency and lower maintenance compared to rolling element bearings. Rolling element bearings, while simpler and cost-effective, suffer from friction, wear, and limited lifespan due to physical contact between components. Magnetic bearings provide better performance in high-speed and precision applications where minimal vibration and contamination-free environments are critical.

Table of Comparison

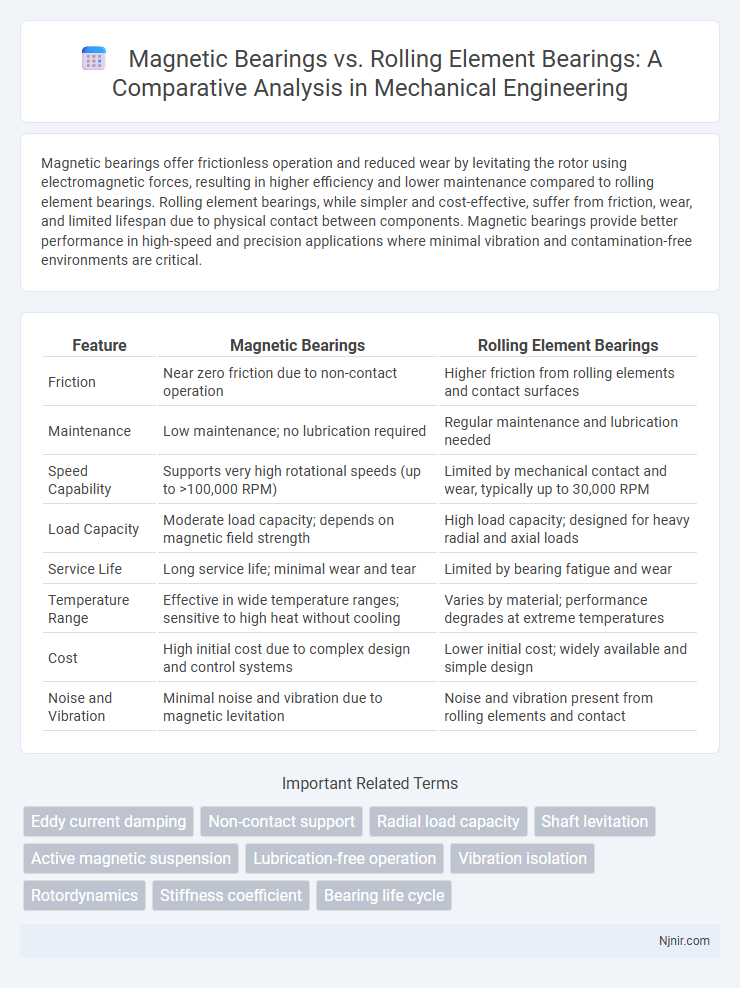

| Feature | Magnetic Bearings | Rolling Element Bearings |

|---|---|---|

| Friction | Near zero friction due to non-contact operation | Higher friction from rolling elements and contact surfaces |

| Maintenance | Low maintenance; no lubrication required | Regular maintenance and lubrication needed |

| Speed Capability | Supports very high rotational speeds (up to >100,000 RPM) | Limited by mechanical contact and wear, typically up to 30,000 RPM |

| Load Capacity | Moderate load capacity; depends on magnetic field strength | High load capacity; designed for heavy radial and axial loads |

| Service Life | Long service life; minimal wear and tear | Limited by bearing fatigue and wear |

| Temperature Range | Effective in wide temperature ranges; sensitive to high heat without cooling | Varies by material; performance degrades at extreme temperatures |

| Cost | High initial cost due to complex design and control systems | Lower initial cost; widely available and simple design |

| Noise and Vibration | Minimal noise and vibration due to magnetic levitation | Noise and vibration present from rolling elements and contact |

Introduction to Bearings in Mechanical Engineering

Magnetic bearings utilize magnetic fields to levitate and support rotating shafts without physical contact, offering low friction and reduced wear compared to rolling element bearings, which rely on balls or rollers to carry load through direct contact. Rolling element bearings are widely used for their simplicity, reliability, and cost-effectiveness in various mechanical applications, but they generate friction, heat, and require regular lubrication and maintenance. Magnetic bearings excel in high-speed, precision environments by minimizing mechanical losses and contamination risks, making them essential in cutting-edge rotating machinery and aerospace engineering.

Fundamentals of Magnetic Bearings

Magnetic bearings support rotating shafts without physical contact by using electromagnetic forces, eliminating friction and wear associated with rolling element bearings. These bearings operate through active control systems that adjust magnetic fields to maintain shaft position, providing high-speed capability and reduced maintenance. Magnetic bearings also enable operation in extreme environments where lubrication is challenging, offering superior performance in precision machinery and turbomachinery applications.

Overview of Rolling Element Bearings

Rolling element bearings consist of rolling balls or rollers placed between inner and outer races, facilitating smooth rotational motion with reduced friction. Common types include ball bearings, cylindrical roller bearings, and tapered roller bearings, each designed for specific load capacities and applications. Their widespread use spans automotive, aerospace, and industrial machinery due to reliability, cost-effectiveness, and ease of maintenance compared to magnetic bearings.

Working Principles: Magnetic vs Rolling Element Bearings

Magnetic bearings operate by using electromagnetic forces to levitate the rotor, eliminating physical contact and reducing friction, wear, and lubrication requirements. Rolling element bearings rely on rolling elements such as balls or rollers positioned between inner and outer races to support the load while allowing rotational movement, but they experience mechanical contact and friction. The non-contact nature of magnetic bearings leads to higher precision and longer service life compared to the mechanical wear in rolling element bearings.

Load Capacity Comparison

Magnetic bearings provide higher load capacity than rolling element bearings by supporting loads through magnetic levitation, eliminating physical contact and wear. Rolling element bearings rely on rolling elements to carry loads, which limits their capacity due to friction, wear, and material fatigue. Advanced magnetic bearing systems can sustain dynamic loads exceeding those of traditional rolling element bearings, making them ideal for high-speed and precision applications.

Efficiency and Energy Consumption

Magnetic bearings demonstrate superior efficiency compared to rolling element bearings due to the near-frictionless magnetic levitation that significantly reduces mechanical losses and lowers energy consumption by up to 60%. Rolling element bearings encounter continuous friction between rolling components and races, leading to higher energy dissipation and increased maintenance requirements. The reduced wear and absence of lubrication in magnetic bearings contribute to longer service life and lower operational costs in high-speed and precision applications.

Maintenance Requirements and Longevity

Magnetic bearings require minimal maintenance due to the lack of physical contact, resulting in reduced wear and extended service life compared to rolling element bearings. Rolling element bearings experience mechanical friction and wear, necessitating regular lubrication and periodic replacement to maintain optimal performance. The superior longevity of magnetic bearings makes them ideal for high-speed, precision applications where downtime and maintenance costs must be minimized.

Vibration and Noise Performance

Magnetic bearings provide superior vibration isolation and significantly reduce noise levels compared to rolling element bearings due to their contactless operation, which eliminates mechanical friction and wear. Rolling element bearings generate higher vibration and noise caused by ball or roller elements contacting races, leading to surface irregularities and operational noise. The enhanced vibration damping and near-silent performance of magnetic bearings make them ideal for high-speed, precision applications demanding minimal acoustic disturbance.

Application Areas and Industry Use Cases

Magnetic bearings are predominantly used in high-speed industrial applications such as turbomachinery, flywheel energy storage, and vacuum pumps due to their frictionless operation and ability to function without lubrication, enhancing performance in aerospace, power generation, and semiconductor manufacturing. Rolling element bearings remain the preferred choice for conventional machinery including automotive wheel hubs, electric motors, and conveyor systems because of their robustness, lower initial cost, and widespread availability across industries like automotive, manufacturing, and heavy equipment. The selection typically depends on operational parameters, with magnetic bearings favored in precision, high-speed environments and rolling element bearings dominating standard mechanical load scenarios.

Cost Analysis and Future Trends

Magnetic bearings typically incur higher initial costs due to complex control systems and precision manufacturing, but offer lower maintenance expenses and longer lifespans compared to rolling element bearings, which have lower upfront costs but higher wear-related expenses. Future trends indicate increasing adoption of magnetic bearings driven by advances in power electronics and sensor technology, reducing costs and improving reliability. Innovations in materials and AI-based monitoring also promise to enhance performance and cost-efficiency for both bearing types.

Eddy current damping

Magnetic bearings minimize friction and wear through non-contact support while rolling element bearings provide mechanical contact, with eddy current damping in magnetic bearings significantly reducing vibration and enhancing stability.

Non-contact support

Magnetic bearings provide non-contact support by using magnetic fields to levitate the rotor, eliminating friction and wear common in rolling element bearings.

Radial load capacity

Magnetic bearings provide lower radial load capacity compared to rolling element bearings, which can typically support higher radial loads due to physical contact between rolling elements and races.

Shaft levitation

Magnetic bearings enable frictionless shaft levitation using electromagnetic forces, significantly reducing wear and maintenance compared to traditional rolling element bearings that rely on physical contact.

Active magnetic suspension

Active magnetic suspension in magnetic bearings eliminates friction and wear found in rolling element bearings, offering precise rotordynamic control and extended operational lifespan.

Lubrication-free operation

Magnetic bearings provide lubrication-free operation by using magnetic fields to support loads without physical contact, unlike rolling element bearings that require continuous lubrication to reduce friction and wear.

Vibration isolation

Magnetic bearings provide superior vibration isolation compared to rolling element bearings by eliminating mechanical contact and reducing friction-induced disturbances.

Rotordynamics

Magnetic bearings offer superior rotordynamics performance by minimizing friction and vibration compared to rolling element bearings, enabling higher rotational speeds and improved rotor stability.

Stiffness coefficient

Magnetic bearings provide a higher stiffness coefficient than rolling element bearings, enabling superior vibration control and precision in high-speed rotating machinery.

Bearing life cycle

Magnetic bearings offer significantly longer life cycles than rolling element bearings by eliminating physical contact and reducing wear, resulting in minimal maintenance and improved reliability.

Magnetic bearings vs Rolling element bearings Infographic

njnir.com

njnir.com