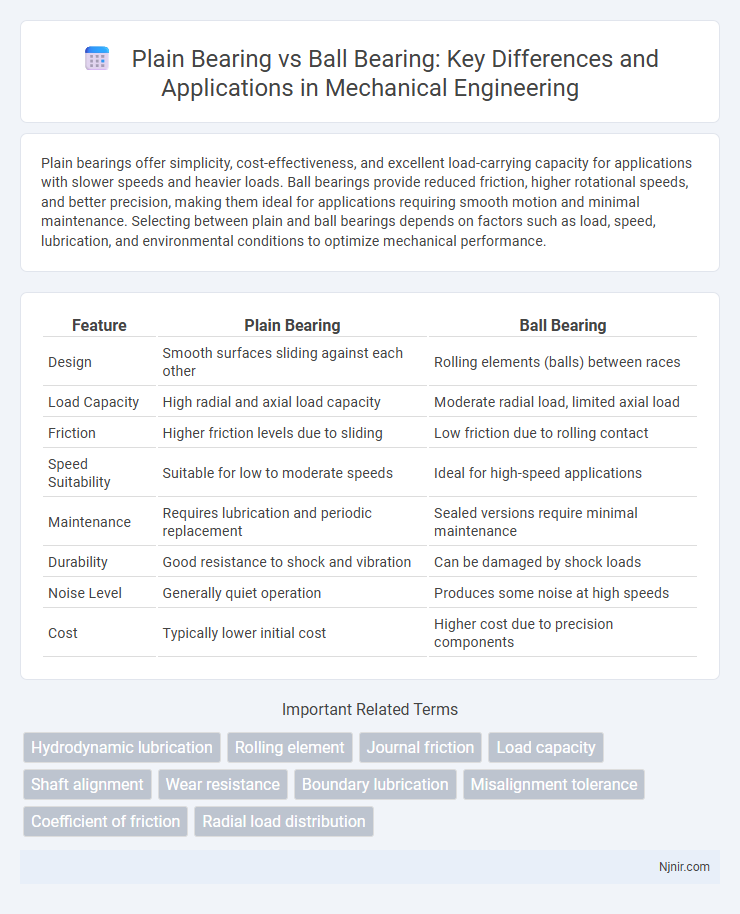

Plain bearings offer simplicity, cost-effectiveness, and excellent load-carrying capacity for applications with slower speeds and heavier loads. Ball bearings provide reduced friction, higher rotational speeds, and better precision, making them ideal for applications requiring smooth motion and minimal maintenance. Selecting between plain and ball bearings depends on factors such as load, speed, lubrication, and environmental conditions to optimize mechanical performance.

Table of Comparison

| Feature | Plain Bearing | Ball Bearing |

|---|---|---|

| Design | Smooth surfaces sliding against each other | Rolling elements (balls) between races |

| Load Capacity | High radial and axial load capacity | Moderate radial load, limited axial load |

| Friction | Higher friction levels due to sliding | Low friction due to rolling contact |

| Speed Suitability | Suitable for low to moderate speeds | Ideal for high-speed applications |

| Maintenance | Requires lubrication and periodic replacement | Sealed versions require minimal maintenance |

| Durability | Good resistance to shock and vibration | Can be damaged by shock loads |

| Noise Level | Generally quiet operation | Produces some noise at high speeds |

| Cost | Typically lower initial cost | Higher cost due to precision components |

Introduction to Plain Bearings and Ball Bearings

Plain bearings, often referred to as sleeve or journal bearings, provide smooth rotational movement by utilizing a sliding motion between surfaces, typically requiring lubrication to minimize friction and wear. Ball bearings use balls as rolling elements within an inner and outer race, significantly reducing friction and enabling efficient high-speed rotation under various loads. Both types are crucial in mechanical systems, with plain bearings favored for heavy loads and low-speed applications, while ball bearings excel in precision and high-speed environments.

Construction and Design Differences

Plain bearings feature a simple design with a smooth surface that supports sliding motion, relying on lubrication to minimize friction and wear. Ball bearings incorporate rolling elements, specifically steel or ceramic balls, housed between inner and outer rings to reduce friction via rolling contact. The construction of plain bearings offers compactness and fewer moving parts, while ball bearings provide higher precision and efficiency in rotational applications due to their engineered cage and raceway design.

Material Selection for Bearings

Material selection for plain bearings often involves bronze, graphite, or PTFE composites due to their excellent load-carrying capacity and low friction properties under moderate speeds and heavy loads. Ball bearings typically use hardened steel or ceramic materials, optimizing durability and high-speed performance with reduced friction and wear resistance. Choosing the right material depends on operating conditions such as load, speed, temperature, and lubrication availability to ensure optimal bearing lifespan and efficiency.

Load Carrying Capacities

Plain bearings exhibit higher load carrying capacities due to their larger contact surface area, distributing loads more evenly and reducing stress concentrations. Ball bearings handle loads through point contact, limiting their capacity under heavy or shock load conditions but offering lower friction and precise rotational movement. Selecting between plain and ball bearings depends on specific load requirements, with plain bearings preferred for heavy, slow-moving applications and ball bearings suited for lighter, high-speed scenarios.

Friction and Efficiency Comparison

Plain bearings exhibit higher friction due to direct surface contact, resulting in lower efficiency compared to ball bearings, which reduce friction by using rolling elements. Ball bearings typically achieve friction coefficients as low as 0.001 to 0.005, while plain bearings may range from 0.01 to 0.1 depending on lubrication and materials. The reduced friction in ball bearings enhances mechanical efficiency and heat dissipation, making them preferable for high-speed and precision applications.

Lubrication Needs and Maintenance

Plain bearings require consistent lubrication to minimize friction and prevent wear, often needing oil or grease applied at regular intervals for optimal performance. Ball bearings typically contain sealed lubrication, reducing maintenance frequency, but still demand periodic inspection to ensure lubricant integrity and avoid contamination. Proper lubrication management extends the lifespan of both bearing types, with plain bearings being more sensitive to lubrication quality and maintenance schedules.

Typical Applications in Mechanical Engineering

Plain bearings excel in heavy-load, low-speed applications such as construction machinery, automotive suspension systems, and industrial presses, where durability and low maintenance are critical. Ball bearings are preferred in high-speed, precision environments like electric motors, aerospace components, and machine tool spindles due to their low friction and accurate rotational performance. Selecting between plain and ball bearings depends on factors like load capacity, speed, operating conditions, and maintenance requirements in mechanical engineering design.

Advantages of Plain Bearings

Plain bearings offer advantages such as lower cost and simpler design compared to ball bearings, making them ideal for applications requiring high load capacity and low-speed operation. They provide superior damping characteristics and can handle shock loads and misalignments with less wear and maintenance. Their ability to operate quietly and resist contamination makes plain bearings suitable for harsh environments and continuous-duty machinery.

Advantages of Ball Bearings

Ball bearings provide significantly lower friction compared to plain bearings, enhancing mechanical efficiency and reducing energy consumption. They offer superior load capacity and durability in high-speed applications due to their rolling elements, which minimize surface contact. Maintenance intervals are extended with ball bearings as they require less frequent lubrication and experience less wear under dynamic loads.

Selection Criteria: Choosing Between Plain and Ball Bearings

Selection between plain and ball bearings depends heavily on load capacity, speed requirements, and operating environment. Plain bearings excel in high-load, low-speed applications with heavy radial loads and offer superior vibration damping and noise reduction, while ball bearings are preferred for high-speed operations requiring precise rotational accuracy and lower friction. Material compatibility, maintenance frequency, and cost considerations also influence the decision, with plain bearings often requiring less maintenance but ball bearings providing longer service life in cleaner, high-speed settings.

Hydrodynamic lubrication

Plain bearings rely on hydrodynamic lubrication to create a fluid film that separates surfaces and reduces friction, whereas ball bearings primarily utilize rolling elements with minimal reliance on hydrodynamic lubrication.

Rolling element

Ball bearings use rolling elements such as balls to reduce friction between moving parts, whereas plain bearings rely on sliding motion without rolling elements, resulting in different performance characteristics and applications.

Journal friction

Plain bearings exhibit higher journal friction due to sliding contact, while ball bearings reduce journal friction significantly by utilizing rolling elements.

Load capacity

Plain bearings typically offer higher load capacity than ball bearings due to their larger contact area and better distribution of forces.

Shaft alignment

Ball bearings maintain superior shaft alignment by reducing radial and axial play, whereas plain bearings rely on precise shaft fit and lubrication to prevent misalignment and wear.

Wear resistance

Plain bearings offer superior wear resistance in heavy-load, low-speed applications due to their simpler design and self-lubricating properties compared to ball bearings.

Boundary lubrication

Plain bearings use boundary lubrication to reduce friction under high load and low speed by maintaining a thin lubricant film, whereas ball bearings rely more on hydrodynamic lubrication principles with rolling elements minimizing direct surface contact.

Misalignment tolerance

Plain bearings tolerate misalignment up to several degrees due to their simple sliding surface, whereas ball bearings have lower misalignment tolerance, typically limited to less than one degree, to avoid uneven load distribution and premature failure.

Coefficient of friction

Plain bearings typically have a higher coefficient of friction ranging from 0.05 to 0.20, whereas ball bearings exhibit a much lower coefficient of friction around 0.001 to 0.005, resulting in greater efficiency and reduced energy loss.

Radial load distribution

Plain bearings distribute radial loads evenly across a larger surface area, reducing stress concentrations, while ball bearings concentrate radial loads on small contact points, enabling higher speed but potentially higher localized stress.

plain bearing vs ball bearing Infographic

njnir.com

njnir.com