Heat exchangers transfer thermal energy between fluids to regulate temperature in various mechanical processes, while intercoolers specifically cool compressed air in turbocharged or supercharged engines to improve efficiency and reduce engine knock. Both devices enhance system performance by managing heat, but intercoolers are specialized heat exchangers designed for air-to-air or air-to-liquid cooling in forced induction systems. Selecting the appropriate device depends on application requirements, thermal load, and fluid types involved.

Table of Comparison

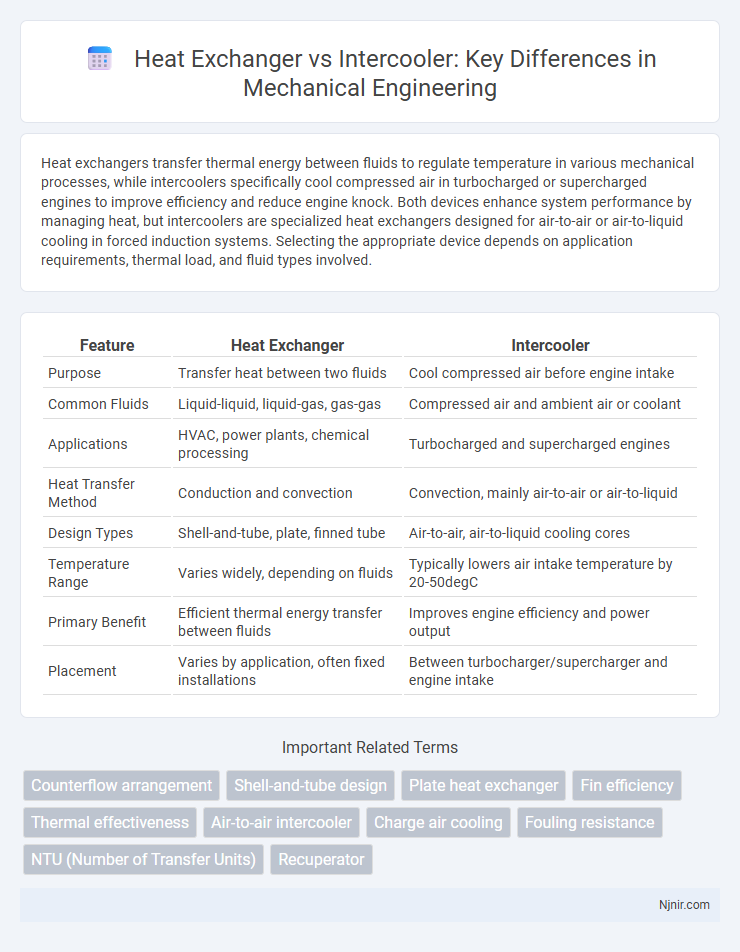

| Feature | Heat Exchanger | Intercooler |

|---|---|---|

| Purpose | Transfer heat between two fluids | Cool compressed air before engine intake |

| Common Fluids | Liquid-liquid, liquid-gas, gas-gas | Compressed air and ambient air or coolant |

| Applications | HVAC, power plants, chemical processing | Turbocharged and supercharged engines |

| Heat Transfer Method | Conduction and convection | Convection, mainly air-to-air or air-to-liquid |

| Design Types | Shell-and-tube, plate, finned tube | Air-to-air, air-to-liquid cooling cores |

| Temperature Range | Varies widely, depending on fluids | Typically lowers air intake temperature by 20-50degC |

| Primary Benefit | Efficient thermal energy transfer between fluids | Improves engine efficiency and power output |

| Placement | Varies by application, often fixed installations | Between turbocharger/supercharger and engine intake |

Introduction to Heat Exchanger and Intercooler

Heat exchangers transfer thermal energy between fluids to regulate temperature in industrial processes, using materials with high thermal conductivity to maximize efficiency. Intercoolers are specialized heat exchangers designed to cool compressed air or gas between stages of a turbocharger or supercharger, reducing temperature and increasing density for improved engine performance. Both devices play critical roles in thermal management but cater to distinct applications in energy transfer and engine optimization.

Fundamental Principles of Heat Exchangers

Heat exchangers operate on the fundamental principle of transferring thermal energy between two or more fluids without mixing them, typically through conduction and convection across a solid boundary. Intercoolers, a specific type of heat exchanger, are designed to reduce the temperature of compressed air between stages of a turbocharged or supercharged engine, improving efficiency and preventing engine knocking. Both devices rely on maximizing surface area, optimizing flow patterns, and maintaining effective temperature gradients to enhance heat transfer rates.

Core Functions of Intercoolers

Intercoolers primarily function to cool the compressed air from the turbocharger or supercharger before it enters the engine, reducing air temperature and increasing air density for improved combustion efficiency. By lowering intake air temperature, intercoolers enhance engine power output, reduce the risk of engine knock, and improve overall performance. Heat exchangers, in contrast, broadly transfer heat between fluids without the specific goal of cooling compressed intake air.

Key Differences between Heat Exchanger and Intercooler

Heat exchangers transfer heat between two or more fluids without mixing them, commonly used in heating, cooling, or energy recovery systems, whereas intercoolers specifically cool compressed air in turbocharged or supercharged engines to increase efficiency and performance. Heat exchangers include various types like shell-and-tube, plate, and finned-tube designs, while intercoolers are typically air-to-air or air-to-liquid devices focused on reducing intake air temperature. The primary difference lies in their application scope and design; heat exchangers serve broader industrial thermal management, while intercoolers are specialized for internal combustion engine efficiency.

Types of Heat Exchangers Used in Engineering

Shell and tube heat exchangers, plate heat exchangers, and finned tube heat exchangers are commonly used types in engineering applications for heat transfer between fluids. Intercoolers, a specific type of heat exchanger typically seen in turbocharged engines, often utilize air-to-air or air-to-liquid configurations to reduce the temperature of compressed air between stages. Plate heat exchangers offer high efficiency in compact spaces, while shell and tube designs handle high-pressure operations, making both types versatile across various industrial cooling and heating processes.

Types of Intercoolers and Their Applications

Air-to-air and air-to-liquid intercoolers are the primary types used in automotive and industrial applications, designed to reduce intake air temperature for improved engine performance. Air-to-air intercoolers utilize ambient air to dissipate heat and are common in turbocharged vehicles due to their simplicity and durability. Air-to-liquid intercoolers rely on a coolant to transfer heat, making them ideal for high-performance engines where space constraints or higher cooling efficiency is required.

Performance Metrics: Efficiency and Effectiveness

Heat exchangers and intercoolers are evaluated primarily by their thermal efficiency and heat transfer effectiveness, with intercoolers specifically designed to reduce temperature between compressor stages in forced induction engines, thereby improving air density and engine performance. Heat exchanger efficiency is assessed by its ability to transfer heat with minimal energy loss, often quantified by the NTU (Number of Transfer Units) method, while intercooler effectiveness is measured by its capacity to lower intake air temperature close to ambient levels, enhancing combustion and reducing knock. Both devices impact performance metrics by optimizing thermal management but differ in application scope, where intercoolers focus on boosting engine power output and heat exchangers serve broader industrial and HVAC functions.

Common Materials and Design Considerations

Heat exchangers and intercoolers commonly use materials such as stainless steel, aluminum, and copper due to their excellent thermal conductivity and corrosion resistance. Design considerations for heat exchangers prioritize maximizing surface area for efficient heat transfer and minimizing pressure drop, while intercoolers focus on compactness, airflow optimization, and durability under high thermal and pressure stresses. Both systems often incorporate finned tubing and shell-and-tube or plate configurations to balance performance with cost and maintenance needs.

Real-World Applications in Mechanical Systems

Heat exchangers and intercoolers serve critical roles in mechanical systems by managing thermal energy to enhance performance and efficiency. Heat exchangers transfer heat between fluids in HVAC systems, power plants, and industrial processes, optimizing energy use and system reliability. Intercoolers specifically cool compressed air in automotive turbochargers, aircraft engines, and heavy machinery, improving engine power output and reducing thermal stress.

Selection Criteria: Choosing Between Heat Exchanger and Intercooler

Selection criteria between a heat exchanger and an intercooler depend on the application's thermal management needs and operating conditions. Heat exchangers are ideal for transferring heat between two fluids across a medium, offering versatility in industrial processes with varying temperature ranges and fluid types. Intercoolers specialize in cooling compressed air or gases, optimizing engine efficiency by reducing intake air temperature and improving combustion performance in turbocharged or supercharged engines.

Counterflow arrangement

Counterflow heat exchangers provide higher thermal efficiency than intercoolers by maintaining a greater temperature gradient between fluids across the entire length of the exchanger.

Shell-and-tube design

Shell-and-tube heat exchangers feature a robust design with multiple tubes enclosed within a cylindrical shell, efficiently facilitating heat transfer between fluids, while intercoolers, often a type of shell-and-tube heat exchanger, specifically reduce intake air temperature in turbocharged engines to improve performance and prevent engine knock.

Plate heat exchanger

Plate heat exchangers provide efficient thermal transfer with compact design and high surface area, making them ideal for applications requiring effective heat exchange, whereas intercoolers specifically cool compressed air in engines to improve performance and reduce intake temperatures.

Fin efficiency

Intercoolers typically have higher fin efficiency than heat exchangers due to their optimized fin design for enhanced heat transfer in high-pressure, high-temperature air systems.

Thermal effectiveness

Heat exchangers typically achieve higher thermal effectiveness than intercoolers due to their optimized surface area and fluid flow configurations designed for maximum heat transfer efficiency.

Air-to-air intercooler

Air-to-air intercoolers, a type of heat exchanger, efficiently cool compressed intake air by transferring heat to ambient air, improving engine performance and reducing intake air temperature more effectively than standard heat exchangers designed for fluid-to-fluid applications.

Charge air cooling

An intercooler specifically cools charge air between turbocharger stages to enhance engine efficiency and reduce combustion temperatures, while a generic heat exchanger transfers heat between fluids in various systems without exclusively focusing on charge air cooling.

Fouling resistance

Intercoolers typically exhibit lower fouling resistance compared to heat exchangers due to their design optimized for cooling compressed air, which reduces particulate buildup and enhances heat transfer efficiency.

NTU (Number of Transfer Units)

The NTU (Number of Transfer Units) method quantifies heat exchanger effectiveness by comparing the ratio of actual heat transfer to the maximum possible, whereas intercoolers typically exhibit higher NTU values due to enhanced heat exchange surface area and airflow rates.

Recuperator

A recuperator is a type of heat exchanger designed to recover waste heat from exhaust gases to preheat incoming air or fluid, enhancing energy efficiency and reducing fuel consumption in systems like gas turbines and furnaces.

heat exchanger vs intercooler Infographic

njnir.com

njnir.com