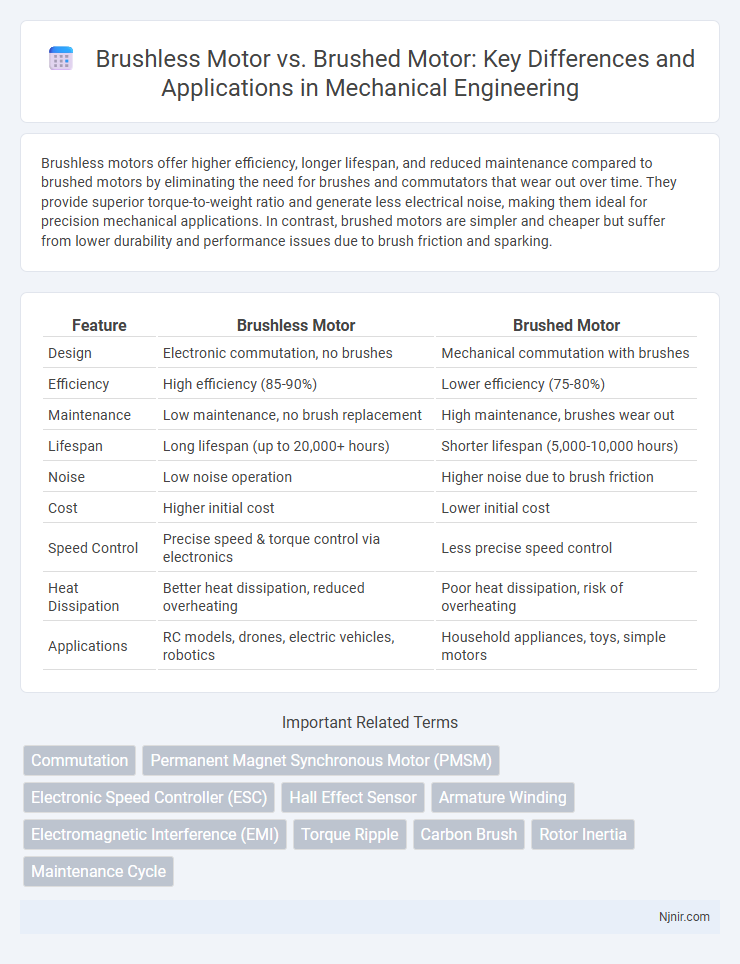

Brushless motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed motors by eliminating the need for brushes and commutators that wear out over time. They provide superior torque-to-weight ratio and generate less electrical noise, making them ideal for precision mechanical applications. In contrast, brushed motors are simpler and cheaper but suffer from lower durability and performance issues due to brush friction and sparking.

Table of Comparison

| Feature | Brushless Motor | Brushed Motor |

|---|---|---|

| Design | Electronic commutation, no brushes | Mechanical commutation with brushes |

| Efficiency | High efficiency (85-90%) | Lower efficiency (75-80%) |

| Maintenance | Low maintenance, no brush replacement | High maintenance, brushes wear out |

| Lifespan | Long lifespan (up to 20,000+ hours) | Shorter lifespan (5,000-10,000 hours) |

| Noise | Low noise operation | Higher noise due to brush friction |

| Cost | Higher initial cost | Lower initial cost |

| Speed Control | Precise speed & torque control via electronics | Less precise speed control |

| Heat Dissipation | Better heat dissipation, reduced overheating | Poor heat dissipation, risk of overheating |

| Applications | RC models, drones, electric vehicles, robotics | Household appliances, toys, simple motors |

Introduction to Brushed and Brushless Motors

Brushed motors use physical brushes and a commutator to transfer electrical current, causing mechanical wear and requiring regular maintenance. Brushless motors eliminate brushes by using electronic controllers to manage the current, enhancing efficiency, reliability, and lifespan. This fundamental design difference impacts performance, noise levels, and suitability for various applications.

Fundamental Working Principles

Brushless motors operate using electronic commutation to switch current in the motor coils, eliminating the need for physical brushes and reducing wear and electrical noise. Brushed motors rely on mechanical commutation with brushes and a commutator to deliver current to the rotating armature windings, causing friction and faster wear. The fundamental difference lies in brushless motors using permanent magnets on the rotor and controlled stator windings, whereas brushed motors have the armature as the rotor and the field windings or magnets stationary.

Construction and Design Differences

Brushless motors utilize electronic commutation and feature permanent magnets on the rotor with stationary windings on the stator, enabling higher efficiency and reduced wear. Brushed motors rely on mechanical commutation through brushes and a commutator, placing windings on the rotor that experience physical contact and friction. The absence of brushes in brushless motors results in a more compact design, less maintenance, and improved durability compared to the simpler but wear-prone construction of brushed motors.

Efficiency and Performance Comparison

Brushless motors deliver significantly higher efficiency compared to brushed motors, often reaching up to 85-90% efficiency due to reduced friction and no commutator wear. Performance-wise, brushless motors provide superior power-to-weight ratios, longer operational lifespan, and smoother operation because of precise electronic control and lack of brush sparking. In contrast, brushed motors suffer from mechanical wear, lower efficiency around 70-75%, and limited speed control, making them less suitable for high-performance applications.

Maintenance Requirements and Lifespan

Brushless motors require significantly less maintenance than brushed motors due to the absence of brushes that wear out and need periodic replacement. The lifespan of brushless motors is considerably longer, often exceeding 20,000 operational hours, compared to the 5,000 to 10,000 hours typical for brushed motors. Reduced mechanical wear and lower heat generation in brushless motors contribute to their enhanced durability and reliability in various applications.

Cost Analysis and Market Trends

Brushless motors typically have higher upfront costs but offer greater efficiency, longer lifespan, and lower maintenance expenses compared to brushed motors, which are cheaper initially but wear out faster due to brush friction. Market trends indicate growing demand for brushless motors in electric vehicles, drones, and industrial applications driven by advancements in power electronics and rising emphasis on energy efficiency. Cost analysis reveals that despite the higher initial investment, the total cost of ownership for brushless motors is lower over time, driving increased adoption across multiple sectors.

Application Suitability in Mechanical Engineering

Brushless motors offer superior efficiency, longer lifespan, and reduced maintenance, making them ideal for precision applications in mechanical engineering such as robotics, CNC machines, and aerospace systems. Brushed motors, with their simpler design and lower initial cost, remain suitable for less demanding tasks like basic conveyor belts and household appliances. The choice depends on the specific application requirements, including torque, speed control, environmental conditions, and budget constraints.

Control Systems and Electronics

Brushless motors utilize electronic commutation via sensors or sensorless control algorithms, enabling precise and efficient speed and torque regulation compared to brushed motors, which rely on mechanical brushes for commutation that limit durability and control accuracy. The absence of brushes in brushless motors reduces electromagnetic interference and maintenance requirements, facilitating integration with advanced digital controllers and sophisticated feedback systems. Enhanced control electronics in brushless motor systems allow for programmable parameters, smoother operation, and better thermal management, making them ideal for applications demanding high performance and reliability.

Noise, Heat, and Environmental Considerations

Brushless motors operate with significantly less noise due to the absence of brushes that cause friction and electrical arcing in brushed motors. They generate less heat because of higher efficiency, which reduces energy loss as heat, extending motor lifespan and improving performance. Environmentally, brushless motors produce fewer electromagnetic emissions and require less maintenance, making them a cleaner, more sustainable choice compared to the wear-prone, brush-dependent brushed motors.

Future Developments and Innovations

Brushless motors are advancing rapidly with innovations in sensorless technology and integrated smart controllers that enhance efficiency and durability compared to traditional brushed motors, which face limitations due to brush wear and maintenance needs. Future developments include the integration of AI-driven motor management systems and materials like graphene to improve thermal conductivity and reduce weight, positioning brushless motors as the preferred choice for electric vehicles and robotics. Industry trends indicate a shift toward brushless designs in renewable energy applications, leveraging their longer lifespan and higher power-to-weight ratio for sustainable growth.

Commutation

Brushless motors use electronic commutation for precise control and higher efficiency, while brushed motors rely on mechanical commutation with carbon brushes, causing more wear and maintenance.

Permanent Magnet Synchronous Motor (PMSM)

Permanent Magnet Synchronous Motors (PMSMs) offer superior efficiency, longer lifespan, and higher power density compared to traditional brushed motors due to their brushless design and precise electronic commutation.

Electronic Speed Controller (ESC)

Brushless motors require specialized Electronic Speed Controllers (ESCs) that use Hall sensor feedback or sensorless back-EMF detection for precise commutation, while brushed motors use simpler ESCs that control voltage directly to the brushes.

Hall Effect Sensor

Brushless motors use Hall Effect sensors for precise rotor position detection, enabling efficient commutation and improved performance compared to brushed motors with mechanical brushes.

Armature Winding

Brushless motors use electronic commutation eliminating armature winding on the rotor, while brushed motors have armature windings on the rotor requiring physical brushes for current transfer.

Electromagnetic Interference (EMI)

Brushless motors generate significantly lower electromagnetic interference (EMI) compared to brushed motors due to the absence of commutator brushes and sparking, resulting in cleaner electrical signals and reduced noise in sensitive electronic applications.

Torque Ripple

Brushless motors exhibit significantly lower torque ripple than brushed motors due to their electronic commutation and precise magnetic field control.

Carbon Brush

Brushless motors eliminate the need for carbon brushes, reducing maintenance and improving efficiency compared to brushed motors that rely on carbon brushes for electrical contact.

Rotor Inertia

Brushless motors have lower rotor inertia than brushed motors due to their lightweight, magnet-based rotors, resulting in faster acceleration and improved efficiency.

Maintenance Cycle

Brushless motors require significantly less frequent maintenance cycles compared to brushed motors due to the absence of brushes and commutators, reducing wear and extending operational lifespan.

Brushless motor vs Brushed motor Infographic

njnir.com

njnir.com