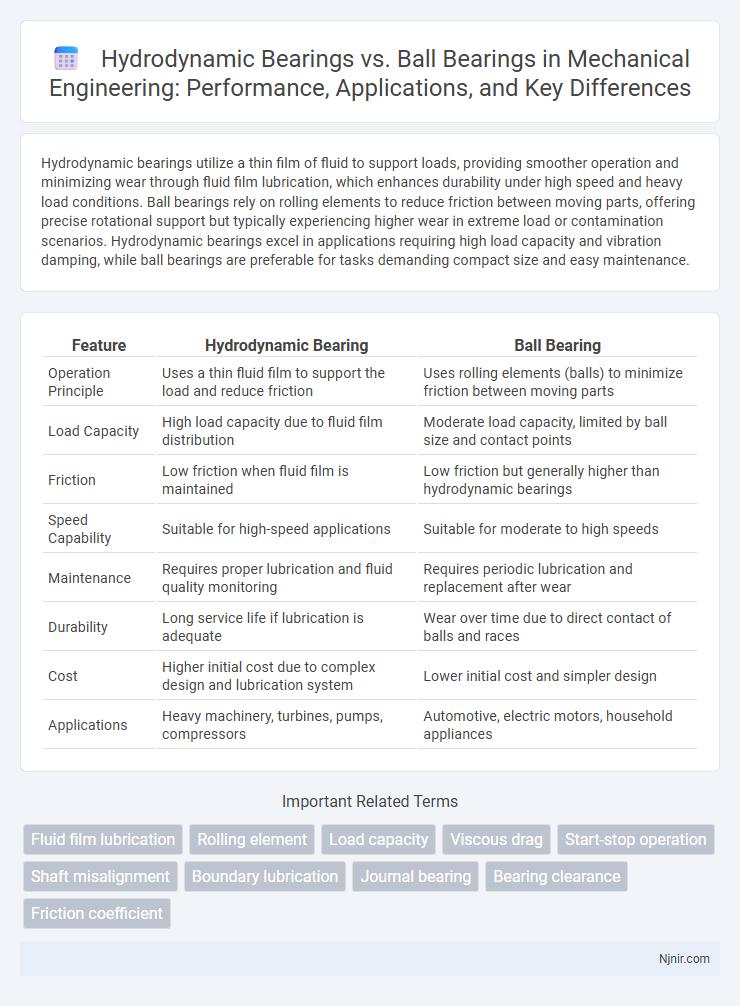

Hydrodynamic bearings utilize a thin film of fluid to support loads, providing smoother operation and minimizing wear through fluid film lubrication, which enhances durability under high speed and heavy load conditions. Ball bearings rely on rolling elements to reduce friction between moving parts, offering precise rotational support but typically experiencing higher wear in extreme load or contamination scenarios. Hydrodynamic bearings excel in applications requiring high load capacity and vibration damping, while ball bearings are preferable for tasks demanding compact size and easy maintenance.

Table of Comparison

| Feature | Hydrodynamic Bearing | Ball Bearing |

|---|---|---|

| Operation Principle | Uses a thin fluid film to support the load and reduce friction | Uses rolling elements (balls) to minimize friction between moving parts |

| Load Capacity | High load capacity due to fluid film distribution | Moderate load capacity, limited by ball size and contact points |

| Friction | Low friction when fluid film is maintained | Low friction but generally higher than hydrodynamic bearings |

| Speed Capability | Suitable for high-speed applications | Suitable for moderate to high speeds |

| Maintenance | Requires proper lubrication and fluid quality monitoring | Requires periodic lubrication and replacement after wear |

| Durability | Long service life if lubrication is adequate | Wear over time due to direct contact of balls and races |

| Cost | Higher initial cost due to complex design and lubrication system | Lower initial cost and simpler design |

| Applications | Heavy machinery, turbines, pumps, compressors | Automotive, electric motors, household appliances |

Introduction to Hydrodynamic and Ball Bearings

Hydrodynamic bearings utilize a thin layer of fluid to support load and reduce friction between moving surfaces, relying on fluid film pressure generated by relative motion. Ball bearings consist of steel or ceramic balls placed between inner and outer races, designed to reduce rotational friction and support radial and axial loads through rolling motion. The key difference lies in hydrodynamic bearings providing fluid-based lubrication and contactless support, while ball bearings rely on rolling elements for mechanical separation.

Basic Operating Principles

Hydrodynamic bearings operate by creating a fluid film that separates the shaft from the bearing surface, relying on fluid pressure generated by relative motion to support loads and minimize friction. In contrast, ball bearings use rolling elements--steel balls--to reduce friction by replacing sliding motion with rolling motion between the inner and outer races. Hydrodynamic bearings excel in high-load, low-speed applications with excellent damping characteristics, while ball bearings are suited for moderate loads and higher-speed applications with predictable rolling resistance.

Key Components and Materials

Hydrodynamic bearings utilize a thin film of lubricating fluid to create a pressure cushion supporting the shaft without direct contact, typically composed of materials like babbitt metal, bronze, or polymers to ensure durability and low friction. Ball bearings consist of hardened steel or ceramic balls contained within steel or plastic cages, enabling smooth rotational motion by minimizing surface contact and friction. Key components in hydrodynamic bearings include the bearing shell, journal, and lubricant film, whereas ball bearings rely on inner and outer races, rolling elements, and retainer cages for optimal performance.

Load Capacity Comparison

Hydrodynamic bearings offer superior load capacity compared to ball bearings due to their fluid film that distributes pressure evenly across the surface, reducing metal-to-metal contact and wear. Ball bearings rely on rolling elements that concentrate loads on small points, limiting their ability to handle heavy or shock loads effectively. In high-load applications, hydrodynamic bearings provide better durability and performance by maintaining continuous lubrication and minimizing friction.

Efficiency and Friction Loss Analysis

Hydrodynamic bearings offer superior efficiency compared to ball bearings by maintaining a fluid film that minimizes direct contact and significantly reduces friction losses in high-speed applications. Ball bearings generate higher friction due to metal-to-metal contact between balls and races, leading to increased energy consumption and wear over time. The fluid film in hydrodynamic bearings provides better load distribution, decreasing frictional resistance and improving overall system efficiency in demanding operational conditions.

Typical Applications in Mechanical Engineering

Hydrodynamic bearings are primarily used in high-load, low-speed applications such as turbines, compressors, and large electric motors due to their ability to form a fluid film that minimizes friction and wear. Ball bearings are preferred for high-speed, precision machinery including automotive wheels, electric motors, and aerospace components, where their rolling element design provides low friction and efficient load distribution. Selecting between hydrodynamic and ball bearings depends on factors like load capacity, speed, lubrication conditions, and operational environment in mechanical engineering systems.

Lubrication Methods and Maintenance Requirements

Hydrodynamic bearings use a thin film of lubricating oil maintained by relative motion to create a fluid wedge that supports the load, requiring continuous lubrication and minimal maintenance when operating correctly. Ball bearings rely on grease or oil lubrication contained within the bearing assembly, necessitating periodic replenishment or replacement of the lubricant to prevent wear and overheating. Maintenance for hydrodynamic bearings involves monitoring oil quality and flow, while ball bearings demand regular inspection for lubricant degradation and contamination to ensure optimal performance.

Durability and Service Life

Hydrodynamic bearings offer superior durability and longer service life compared to ball bearings due to their fluid film lubrication, which minimizes metal-to-metal contact and reduces wear. Ball bearings experience more friction and heat generation at contact points, leading to faster degradation under high loads or contamination. The continuous lubrication and lower stress concentrations in hydrodynamic bearings make them ideal for heavy-duty applications requiring extended operational longevity.

Cost Considerations and Economic Impact

Hydrodynamic bearings typically have higher initial manufacturing costs due to precise machining and material requirements but offer longer service life and lower maintenance expenses, resulting in reduced total cost of ownership. Ball bearings generally incur lower upfront costs with simpler production processes but may demand more frequent replacement and maintenance, increasing long-term operational expenses. Evaluating cost considerations and economic impact involves balancing initial investment against durability, maintenance cycles, and application-specific performance needs.

Selection Criteria for Engineers

Engineers select hydrodynamic bearings for applications requiring high load capacity, excellent shock absorption, and superior damping at low speeds due to their fluid film lubrication minimizing metal-to-metal contact. Ball bearings are preferred where precision, lower friction, high-speed capability, and compact design are critical, especially in applications with moderate loads and the need for accurate rotational positioning. Key selection criteria include load capacity, operating speed, maintenance requirements, environmental conditions, and cost-effectiveness for optimized system performance.

Fluid film lubrication

Hydrodynamic bearings utilize a continuous fluid film lubrication that separates surfaces to reduce friction and wear, whereas ball bearings rely on rolling elements with minimal fluid film, leading to higher contact stress and potential lubrication challenges.

Rolling element

Rolling element ball bearings use discrete rolling balls to reduce friction, whereas hydrodynamic bearings rely on a continuous fluid film to support loads and minimize direct contact.

Load capacity

Hydrodynamic bearings offer significantly higher load capacity than ball bearings by distributing loads over a fluid film, reducing wear and enabling smoother operation under heavy and continuous loads.

Viscous drag

Hydrodynamic bearings generate lower viscous drag through a continuous lubricant film, whereas ball bearings experience higher viscous drag due to discrete point contacts and rolling resistance.

Start-stop operation

Hydrodynamic bearings excel in start-stop operations by forming a lubricating film only at high speeds, reducing wear during startup, whereas ball bearings provide consistent load support regardless of speed but may experience higher friction and wear during frequent starts and stops.

Shaft misalignment

Hydrodynamic bearings accommodate shaft misalignment better than ball bearings by maintaining a continuous fluid film that adapts to angular deviations, reducing wear and vibration.

Boundary lubrication

Hydrodynamic bearings rely on a full fluid film to maintain separation between surfaces, minimizing boundary lubrication, whereas ball bearings primarily depend on point contact and are more susceptible to boundary lubrication conditions.

Journal bearing

Hydrodynamic journal bearings provide superior load capacity and reduced friction by maintaining a continuous fluid film between the shaft and bearing surface, in contrast to ball bearings which rely on rolling elements and contact points.

Bearing clearance

Hydrodynamic bearings maintain a thin lubricating film with precise bearing clearance to prevent metal-to-metal contact, while ball bearings rely on minimal clearance to support loads through rolling elements.

Friction coefficient

Hydrodynamic bearings typically exhibit a friction coefficient as low as 0.0001 due to the fluid film lubrication, whereas ball bearings have a higher friction coefficient around 0.001 to 0.005 caused by metal-to-metal contact and rolling resistance.

Hydrodynamic bearing vs Ball bearing Infographic

njnir.com

njnir.com