Thermoplastics are polymers that soften when heated and harden upon cooling, allowing for repeated reshaping and recycling, which makes them highly versatile in mechanical engineering applications. Thermosets undergo a chemical curing process that creates a rigid, heat-resistant structure, providing superior mechanical strength and thermal stability but preventing reshaping after curing. The choice between thermoplastics and thermosets depends on factors like application requirements, environmental conditions, and desired material properties such as flexibility, durability, and resistance to heat.

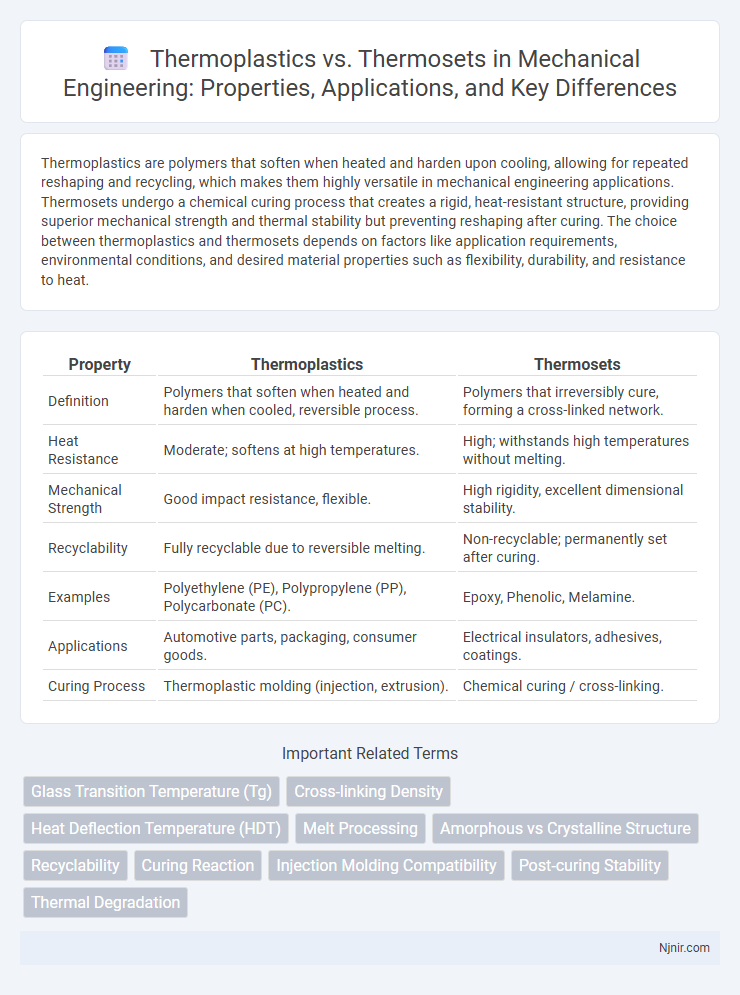

Table of Comparison

| Property | Thermoplastics | Thermosets |

|---|---|---|

| Definition | Polymers that soften when heated and harden when cooled, reversible process. | Polymers that irreversibly cure, forming a cross-linked network. |

| Heat Resistance | Moderate; softens at high temperatures. | High; withstands high temperatures without melting. |

| Mechanical Strength | Good impact resistance, flexible. | High rigidity, excellent dimensional stability. |

| Recyclability | Fully recyclable due to reversible melting. | Non-recyclable; permanently set after curing. |

| Examples | Polyethylene (PE), Polypropylene (PP), Polycarbonate (PC). | Epoxy, Phenolic, Melamine. |

| Applications | Automotive parts, packaging, consumer goods. | Electrical insulators, adhesives, coatings. |

| Curing Process | Thermoplastic molding (injection, extrusion). | Chemical curing / cross-linking. |

Introduction to Thermoplastics and Thermosets

Thermoplastics are polymers that soften on heating and harden upon cooling, allowing repeated reshaping without chemical change, making them ideal for processes like injection molding and extrusion. Thermosets differ by undergoing a chemical curing process that creates a rigid, three-dimensional network, resulting in materials with high thermal stability and mechanical strength that cannot be reshaped once set. These fundamental differences define their applications, with thermoplastics favored for flexibility and recyclability, while thermosets are preferred for durable, heat-resistant components in automotive and aerospace industries.

Chemical Structure and Composition

Thermoplastics consist of long, linear or branched polymer chains that soften upon heating due to weak intermolecular forces, allowing them to be reshaped multiple times. In contrast, thermosets have a highly cross-linked, three-dimensional polymer network created through irreversible chemical bonds formed during curing, resulting in a rigid and heat-resistant structure. This fundamental difference in chemical composition defines their distinct thermal and mechanical properties, with thermoplastics being more flexible and recyclable, while thermosets offer superior structural integrity and durability.

Manufacturing Processes

Thermoplastics are manufactured using processes such as injection molding, extrusion, and blow molding, enabling repeated melting and reshaping due to their reversible thermal properties. Thermosets undergo curing through heat, chemical reactions, or radiation during manufacturing methods like compression molding or transfer molding, resulting in a permanently cross-linked, rigid structure. The manufacturing processes for thermosets do not allow reheating or reshaping, contrasting with the recyclable and versatile thermoplastics.

Mechanical Properties Comparison

Thermoplastics exhibit higher flexibility and impact resistance due to their linear polymer chains, enabling repeated melting and reshaping, whereas thermosets possess a rigid, cross-linked network structure, resulting in superior dimensional stability and heat resistance. The tensile strength of thermosets typically surpasses that of thermoplastics, making them ideal for applications requiring high mechanical strength and thermal durability. However, thermoplastics offer better toughness and are less brittle compared to thermosets, which are prone to cracking under high stress.

Thermal Stability and Performance

Thermoplastics exhibit lower thermal stability compared to thermosets, melting and deforming at elevated temperatures due to their linear polymer chains. Thermosets possess superior thermal performance, maintaining structural integrity and shape retention up to higher temperatures because of their cross-linked molecular network. This makes thermosets ideal for high-temperature applications like electrical insulation and engine components, whereas thermoplastics suit environments with moderate thermal demands.

Recyclability and Environmental Impact

Thermoplastics offer superior recyclability due to their ability to be melted and reshaped multiple times without significant degradation, reducing plastic waste and conserving resources. In contrast, thermosets form irreversible chemical bonds during curing, making them difficult to recycle and often resulting in landfill accumulation or incineration. The environmental impact of thermosets is generally higher because of limited end-of-life options, while thermoplastics contribute to a more circular economy through efficient material recovery processes.

Typical Applications in Mechanical Engineering

Thermoplastics are commonly used in mechanical engineering for manufacturing components such as gears, bearings, and housings due to their excellent impact resistance, flexibility, and recyclability. Thermosets are preferred for applications requiring high thermal stability and mechanical strength, including electrical insulators, automotive parts, and composite structures. Both materials play crucial roles, with thermoplastics enabling lightweight and cost-effective solutions while thermosets provide durability and structural integrity under harsh operating conditions.

Advantages of Thermoplastics Over Thermosets

Thermoplastics offer superior recyclability and reusability compared to thermosets, enabling multiple melting and reshaping cycles without chemical degradation. They typically exhibit greater flexibility and impact resistance, making them ideal for applications requiring durability and complex geometries. Their faster processing times and ability to be molded repeatedly provide cost-effective manufacturing advantages in industries like automotive and packaging.

Limitations and Challenges of Each Material

Thermoplastics face limitations such as lower heat resistance and structural strength compared to thermosets, making them less suitable for high-temperature applications. Thermosets exhibit challenges in recyclability and repair due to their cross-linked molecular structure, resulting in environmental concerns and higher production costs. Both materials require careful selection based on application demands, balancing performance constraints with manufacturing and sustainability factors.

Future Trends in Polymer Selection

Future trends in polymer selection emphasize increased adoption of sustainable thermoplastics due to their recyclability and environmental benefits, contrasting with thermosets' irreversible curing processes. Advances in bio-based thermoplastics and enhanced composite materials are driving innovation in lightweight and high-performance applications across automotive and aerospace sectors. Emerging technologies in chemical recycling and additive manufacturing further position thermoplastics as the preferred choice for circular economy initiatives and customizable polymer solutions.

Glass Transition Temperature (Tg)

Thermoplastics typically exhibit a distinct Glass Transition Temperature (Tg) indicating reversible softening, whereas thermosets have a higher, often less distinct Tg due to their crosslinked, rigid polymer networks.

Cross-linking Density

Thermosets exhibit high cross-linking density that imparts superior heat resistance and structural rigidity compared to the low cross-linking density and greater flexibility of thermoplastics.

Heat Deflection Temperature (HDT)

Thermoplastics generally exhibit lower Heat Deflection Temperatures (HDT), typically ranging from 50degC to 150degC, while thermosets have higher HDT values, often exceeding 200degC, due to their cross-linked polymer structure.

Melt Processing

Thermoplastics can be repeatedly melted and reshaped during melt processing, while thermosets undergo irreversible chemical curing that prevents remelting.

Amorphous vs Crystalline Structure

Thermoplastics typically exhibit amorphous or semi-crystalline structures allowing reversible softening upon heating, whereas thermosets possess rigid, highly cross-linked amorphous networks resulting in permanent hardness and thermal stability.

Recyclability

Thermoplastics offer superior recyclability due to their ability to be repeatedly melted and reshaped, whereas thermosets are irreversibly hardened, making recycling and reprocessing challenging.

Curing Reaction

Thermoplastics undergo physical melting and solidification without chemical curing, while thermosets experience irreversible curing reactions forming cross-linked polymer networks that enhance heat resistance and mechanical strength.

Injection Molding Compatibility

Thermoplastics exhibit superior injection molding compatibility due to their ability to be repeatedly melted and reshaped, unlike thermosets which irreversibly cure and cannot be remelted after molding.

Post-curing Stability

Thermoplastics exhibit superior post-curing stability due to their reversible melting and solidification properties, while thermosets undergo irreversible chemical cross-linking that limits their post-curing thermal and mechanical stability.

Thermal Degradation

Thermoplastics undergo reversible thermal degradation allowing reshaping upon heating, whereas thermosets experience irreversible thermal degradation due to cross-linked polymer structures that prevent remelting.

thermoplastics vs thermosets Infographic

njnir.com

njnir.com