Compliant mechanisms achieve motion through elastic deformation of flexible members, eliminating the need for traditional joints and reducing the number of parts. Rigid mechanisms rely on rigid bodies connected by discrete joints, providing precise motion but often increasing assembly complexity and wear. The advantages of compliant mechanisms include lower manufacturing costs, reduced maintenance, and enhanced reliability due to fewer moving parts prone to friction and backlash.

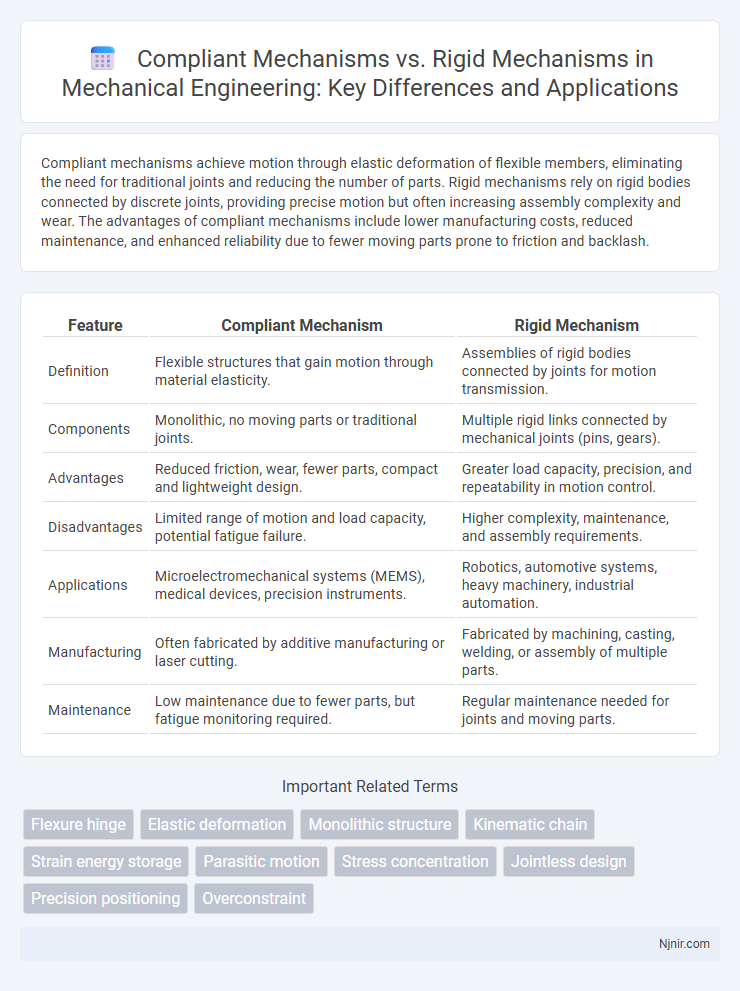

Table of Comparison

| Feature | Compliant Mechanism | Rigid Mechanism |

|---|---|---|

| Definition | Flexible structures that gain motion through material elasticity. | Assemblies of rigid bodies connected by joints for motion transmission. |

| Components | Monolithic, no moving parts or traditional joints. | Multiple rigid links connected by mechanical joints (pins, gears). |

| Advantages | Reduced friction, wear, fewer parts, compact and lightweight design. | Greater load capacity, precision, and repeatability in motion control. |

| Disadvantages | Limited range of motion and load capacity, potential fatigue failure. | Higher complexity, maintenance, and assembly requirements. |

| Applications | Microelectromechanical systems (MEMS), medical devices, precision instruments. | Robotics, automotive systems, heavy machinery, industrial automation. |

| Manufacturing | Often fabricated by additive manufacturing or laser cutting. | Fabricated by machining, casting, welding, or assembly of multiple parts. |

| Maintenance | Low maintenance due to fewer parts, but fatigue monitoring required. | Regular maintenance needed for joints and moving parts. |

Introduction to Compliant and Rigid Mechanisms

Compliant mechanisms achieve motion through the flexibility of their materials, enabling elastic deformation to transmit force and displacement without traditional joints. Rigid mechanisms rely on rigid bodies connected by discrete joints to produce movement, often resulting in higher wear and maintenance demands. The design of compliant mechanisms offers advantages such as reduced part count, increased precision, and improved durability by minimizing friction and backlash.

Fundamental Principles of Compliant Mechanisms

Compliant mechanisms rely on the elastic deformation of flexible materials to achieve motion, eliminating the need for traditional joints and hinges found in rigid mechanisms. These mechanisms leverage intrinsic material properties and geometric design to store and release energy, enabling smooth, precise movements with reduced part counts and no frictional losses. The fundamental principles emphasize monolithic structures that deform predictably under load, enhancing durability and simplifying manufacturing compared to rigid linkage systems.

Key Characteristics of Rigid Mechanisms

Rigid mechanisms are characterized by their use of rigid bodies connected through movable joints, allowing precise and predictable motion paths without deformation of the components. They typically exhibit high stiffness, durability, and load-bearing capacity, making them suitable for applications requiring repeatable and accurate positioning. The reliance on frictionless pivot points or bearings minimizes energy loss, enhancing the mechanical efficiency and reliability of rigid mechanisms.

Comparative Analysis: Flexibility vs. Stiffness

Compliant mechanisms leverage elastic deformation of flexible materials to achieve motion, offering advantages in reduced part count, lower weight, and inherent shock absorption compared to rigid mechanisms that rely on discrete joints and rigid links for movement. The flexibility of compliant mechanisms allows for smoother energy transfer and less maintenance but often comes at the cost of limited load capacity and potential material fatigue, whereas rigid mechanisms provide superior stiffness and load-bearing capabilities critical in high-precision or heavy-duty applications. Engineers must balance the trade-offs between compliant mechanisms' flexibility and adaptability against rigid mechanisms' stiffness and durability based on application requirements such as force transmission, accuracy, and lifecycle performance.

Material Considerations for Both Mechanisms

Compliant mechanisms rely on flexible materials such as elastomers or flexible polymers to enable elastic deformation and store strain energy, which reduces the need for multiple rigid joints. Rigid mechanisms typically use metals or high-stiffness composites to withstand high loads and minimize deflections, providing precise and stable motion through discrete joints. Material selection for compliant mechanisms focuses on fatigue resistance and elastic limits, whereas rigid mechanisms prioritize yield strength and wear resistance to ensure durability and performance.

Common Applications in Mechanical Engineering

Compliant mechanisms are widely used in precision applications such as micro-electromechanical systems (MEMS), flexible couplings, and biomedical devices where elastic deformation provides smooth motion without friction or backlash. Rigid mechanisms dominate in heavy machinery, automotive linkages, and robotic arms due to their superior load-bearing capacity and predictable kinematics through rigid body motion. Both mechanisms are integral in mechanical engineering designs, with compliant mechanisms favored for compact, lightweight solutions and rigid mechanisms preferred for high-strength, durable performance.

Advantages and Limitations of Compliant Mechanisms

Compliant mechanisms offer significant advantages such as reduced part count, lower manufacturing costs, and the ability to achieve complex motions through elastic deformation, resulting in improved reliability and reduced wear compared to rigid mechanisms that rely on traditional joints and linkages. Their inherent flexibility allows for miniaturization and simplified assembly in precision engineering applications like MEMS and biomedical devices. However, limitations include restricted load capacity, potential fatigue failure due to repeated stress, and challenges in accurately predicting nonlinear material behavior during large deformations.

Strengths and Weaknesses of Rigid Mechanisms

Rigid mechanisms exhibit high load-bearing capacity and precise motion control due to their solid, non-deforming components, making them ideal for applications requiring stability and accuracy. However, they are prone to wear and fatigue over time because of friction at joints and require lubrication and maintenance. Their complexity and assembly cost are typically higher compared to compliant mechanisms, limiting versatility in lightweight or flexible applications.

Performance Factors: Precision, Durability, and Maintenance

Compliant mechanisms offer high precision through elastic deformation, reducing backlash and friction compared to rigid mechanisms, which rely on multiple movable joints and tend to suffer from wear-induced looseness. Durability in compliant mechanisms is often enhanced by fewer parts and lower contact stresses, though material fatigue must be managed, whereas rigid mechanisms may face frequent component replacements due to mechanical wear. Maintenance demands for compliant mechanisms are typically lower, as they involve fewer moving interfaces and no lubrication, contrasting with rigid mechanisms that require regular inspection and servicing of joints and bearings.

Future Trends in Mechanism Design and Engineering

Future trends in mechanism design emphasize the integration of compliant mechanisms due to their advantages in flexibility, reduced part counts, and enhanced energy efficiency compared to traditional rigid mechanisms. Innovations in advanced materials such as shape-memory alloys and polymers are driving the adoption of compliant mechanisms in applications including aerospace, biomedical devices, and robotics. Computational optimization techniques and additive manufacturing are further enabling the precise design and fabrication of compliant mechanisms with tailored mechanical properties, surpassing the limitations posed by rigid-body counterparts.

Flexure hinge

Flexure hinges in compliant mechanisms enable precise, frictionless motion through elastic deformation, contrasting with rigid mechanisms that rely on traditional pin joints and suffer from wear and backlash.

Elastic deformation

Compliant mechanisms leverage elastic deformation of flexible materials to achieve motion and force transmission without traditional joints, offering advantages in reduced wear and enhanced precision compared to rigid mechanisms that rely on discrete, rigid-body components and hinges.

Monolithic structure

Compliant mechanisms leverage monolithic structures that enable elastic deformation for motion transmission, reducing assembly complexity and wear compared to traditional rigid mechanisms composed of multiple rigid bodies and joints.

Kinematic chain

Compliant mechanisms utilize flexible kinematic chains to achieve motion through material deformation, unlike rigid mechanisms that rely on assembled rigid links connected by joints for movement.

Strain energy storage

Compliant mechanisms store strain energy through elastic deformation of flexible components, whereas rigid mechanisms rely on discrete joints and minimize strain energy storage by maintaining rigid body motion.

Parasitic motion

Parasitic motion in compliant mechanisms is minimized by flexible deformation of materials, whereas rigid mechanisms generate parasitic motion through unintended clearances and joint play.

Stress concentration

Compliant mechanisms reduce stress concentration by distributing elastic deformation across flexible components, unlike rigid mechanisms that localize stress at joints and hinges.

Jointless design

Compliant mechanisms utilize flexible materials to achieve jointless motion through elastic deformation, eliminating the friction and wear associated with traditional rigid mechanisms that rely on discrete joints.

Precision positioning

Compliant mechanisms achieve higher precision positioning by minimizing backlash and friction through elastic deformation, whereas rigid mechanisms rely on multiple rigid components and joints that can introduce cumulative errors and reduce accuracy.

Overconstraint

Compliant mechanisms reduce overconstraint by utilizing elastic deformation for motion, unlike rigid mechanisms that rely on multiple rigid joints often causing excessive constraints.

Compliant mechanism vs Rigid mechanism Infographic

njnir.com

njnir.com