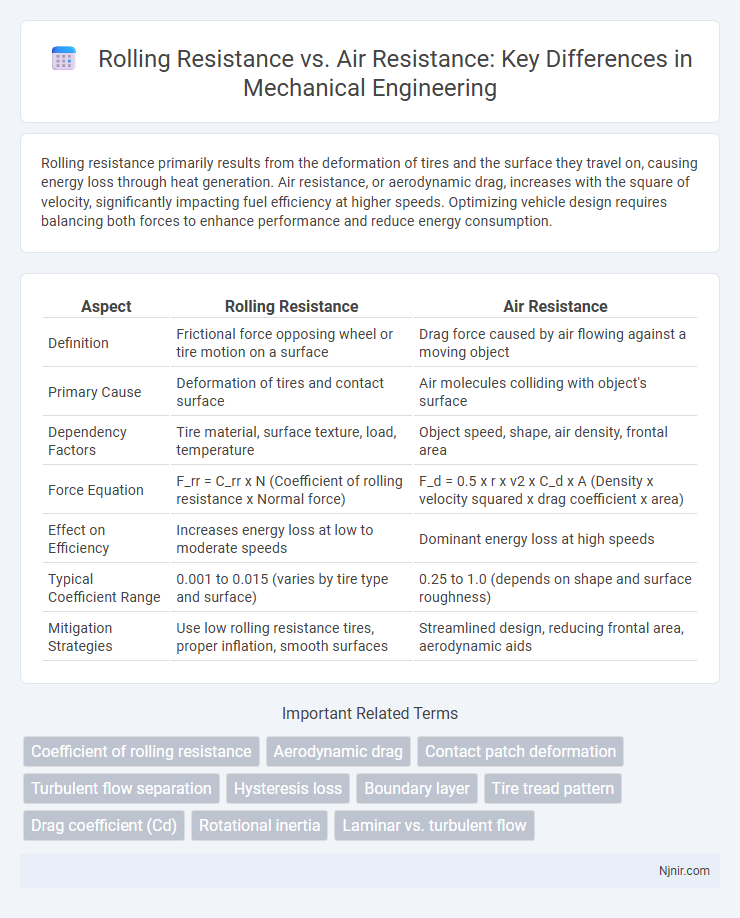

Rolling resistance primarily results from the deformation of tires and the surface they travel on, causing energy loss through heat generation. Air resistance, or aerodynamic drag, increases with the square of velocity, significantly impacting fuel efficiency at higher speeds. Optimizing vehicle design requires balancing both forces to enhance performance and reduce energy consumption.

Table of Comparison

| Aspect | Rolling Resistance | Air Resistance |

|---|---|---|

| Definition | Frictional force opposing wheel or tire motion on a surface | Drag force caused by air flowing against a moving object |

| Primary Cause | Deformation of tires and contact surface | Air molecules colliding with object's surface |

| Dependency Factors | Tire material, surface texture, load, temperature | Object speed, shape, air density, frontal area |

| Force Equation | F_rr = C_rr x N (Coefficient of rolling resistance x Normal force) | F_d = 0.5 x r x v2 x C_d x A (Density x velocity squared x drag coefficient x area) |

| Effect on Efficiency | Increases energy loss at low to moderate speeds | Dominant energy loss at high speeds |

| Typical Coefficient Range | 0.001 to 0.015 (varies by tire type and surface) | 0.25 to 1.0 (depends on shape and surface roughness) |

| Mitigation Strategies | Use low rolling resistance tires, proper inflation, smooth surfaces | Streamlined design, reducing frontal area, aerodynamic aids |

Introduction to Rolling Resistance and Air Resistance

Rolling resistance is the force that opposes the motion of a tire as it rolls over a surface, primarily caused by the deformation of the tire and the road. Air resistance, also known as aerodynamic drag, is the force exerted by air opposing the movement of a vehicle, increasing with speed and shaped by the vehicle's design and frontal area. Understanding the balance between rolling resistance and air resistance is crucial for optimizing vehicle efficiency and fuel consumption.

Fundamental Differences between Rolling and Air Resistance

Rolling resistance arises from the deformation of a tire and the surface it contacts, leading to energy loss primarily through heat dissipation in the contact patch. Air resistance, or aerodynamic drag, results from the interaction between a moving object and air molecules, creating a force that opposes motion and increases with the object's speed and frontal area. The fundamental difference lies in rolling resistance being a mechanical frictional force dependent on materials and surface conditions, while air resistance is a fluid dynamic force influenced by velocity, shape, and air density.

Causes and Mechanisms of Rolling Resistance

Rolling resistance primarily arises from deformation of tires and the surface during motion, causing energy loss through hysteresis in the tire material. The constant flattening and recovery of the tire tread generate heat, which reduces the overall efficiency of vehicle movement. Factors such as tire composition, inflation pressure, and road texture directly influence the magnitude of rolling resistance.

Causes and Mechanisms of Air Resistance

Air resistance, caused by the friction between air molecules and a moving object's surface, results in a drag force opposing motion and increases with speed and surface area. It arises from the need to push air molecules aside, creating a turbulent wake and pressure differences around the object. Rolling resistance primarily stems from deformation of the contact surfaces and energy loss at the tire-road interface, differing fundamentally from the fluid dynamic interactions driving air resistance.

Mathematical Models for Rolling and Air Resistance

Rolling resistance is mathematically modeled as \( F_r = C_r \times N \), where \( C_r \) is the rolling resistance coefficient and \( N \) is the normal force acting on the object. Air resistance, or drag force, follows the equation \( F_d = \frac{1}{2} \rho C_d A v^2 \), with \( \rho \) representing air density, \( C_d \) the drag coefficient, \( A \) the frontal area, and \( v \) the velocity relative to the air. Comparing these models, rolling resistance scales linearly with the normal force, whereas air resistance increases quadratically with speed, making air drag dominant at higher velocities.

Impact of Speed on Rolling vs Air Resistance

Rolling resistance remains relatively constant across varying speeds, primarily influenced by tire material and surface texture. Air resistance, however, increases exponentially with speed, becoming the dominant opposing force as velocity rises above moderate levels. At higher speeds, aerodynamic drag surpasses rolling resistance, significantly impacting vehicle efficiency and fuel consumption.

Influence of Surface and Tire Materials

Rolling resistance is significantly impacted by tire materials and surface texture, with softer compounds increasing deformation and energy loss on rough surfaces. Air resistance, primarily affected by aerodynamic design and speed, remains largely unchanged by tire or surface variations but can indirectly influence rolling resistance through tire deformation at higher speeds. Optimizing tire compounds like silica-enhanced rubber on smooth asphalt surfaces reduces rolling resistance, while textured surfaces amplify resistance regardless of aerodynamic drag factors.

Effects on Energy Consumption and Efficiency

Rolling resistance, caused by deformation of tires and road surface, significantly increases energy consumption especially at lower speeds by requiring more power to maintain motion. Air resistance, or aerodynamic drag, becomes the dominant force at higher speeds, drastically reducing efficiency as the power needed to overcome it rises exponentially with velocity. Optimizing tire design and vehicle aerodynamics can simultaneously minimize rolling and air resistance, enhancing overall energy efficiency and reducing fuel consumption.

Engineering Solutions to Minimize Resistance

Engineering solutions to minimize rolling resistance focus on optimizing tire materials, tread patterns, and inflation pressure to reduce deformation and energy loss. Aerodynamic design improvements, such as streamlined vehicle shapes, smooth underbodies, and active flow control devices, effectively decrease air resistance. Combining low rolling resistance tires with advanced aerodynamic enhancements maximizes overall efficiency in automotive and transportation engineering.

Applications in Automotive and Transportation Design

Rolling resistance and air resistance significantly influence automotive and transportation design by determining fuel efficiency and vehicle performance. Engineers optimize tire materials and tread patterns to minimize rolling resistance, reducing energy loss during ground contact, while aerodynamic shaping of vehicle bodies lowers air resistance to enhance speed and reduce drag. Balancing these forces allows designers to create vehicles that achieve better mileage, improved handling, and lower emissions in real-world driving conditions.

Coefficient of rolling resistance

The coefficient of rolling resistance significantly impacts energy loss in vehicles by quantifying the force resisting wheel rotation, typically ranging from 0.001 to 0.015 for tires, which is generally lower than air resistance but crucial at low speeds.

Aerodynamic drag

Aerodynamic drag, a primary component of air resistance, significantly impacts vehicle efficiency by increasing fuel consumption and reducing speed compared to rolling resistance.

Contact patch deformation

Contact patch deformation primarily increases rolling resistance by causing energy loss through tire material flexing while air resistance remains unaffected by this mechanical factor.

Turbulent flow separation

Turbulent flow separation increases air resistance significantly more than rolling resistance by disrupting airflow and creating drag, especially at higher speeds.

Hysteresis loss

Rolling resistance primarily arises from hysteresis loss in tire materials as they deform and recover during rotation, while air resistance depends on aerodynamic drag forces opposing vehicle motion.

Boundary layer

Boundary layer thickness significantly influences rolling resistance by affecting tire-road contact friction, while its disruption alters airflow patterns, impacting air resistance on moving vehicles.

Tire tread pattern

Tire tread patterns significantly influence rolling resistance by increasing deformation and energy loss, while having a minimal effect on aerodynamic air resistance compared to overall tire shape and vehicle design.

Drag coefficient (Cd)

Rolling resistance primarily depends on tire composition and surface deformation, while air resistance is strongly influenced by the drag coefficient (Cd), which quantifies aerodynamic efficiency and directly affects vehicle fuel consumption and speed.

Rotational inertia

Rotational inertia increases rolling resistance by requiring more energy to overcome wheel spin, while air resistance primarily affects translational motion and becomes dominant at higher speeds.

Laminar vs. turbulent flow

Laminar flow minimizes air resistance by maintaining smooth airflow, while turbulent flow increases air resistance and rolling resistance due to chaotic fluid motion and surface friction.

Rolling resistance vs Air resistance Infographic

njnir.com

njnir.com