Tensile strength measures the maximum stress a material can withstand while being stretched before breaking, whereas yield strength defines the stress level at which a material begins to deform plastically. Understanding the difference between tensile strength and yield strength is crucial for designing mechanical components that must endure specific load conditions without permanent deformation. Selecting materials with appropriate tensile and yield strengths ensures safety, reliability, and durability in engineering applications.

Table of Comparison

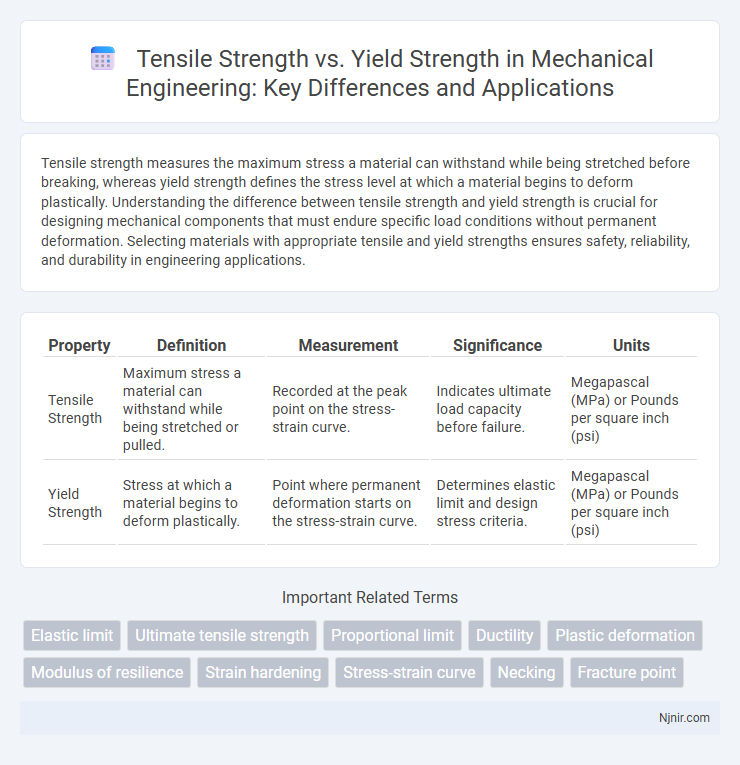

| Property | Definition | Measurement | Significance | Units |

|---|---|---|---|---|

| Tensile Strength | Maximum stress a material can withstand while being stretched or pulled. | Recorded at the peak point on the stress-strain curve. | Indicates ultimate load capacity before failure. | Megapascal (MPa) or Pounds per square inch (psi) |

| Yield Strength | Stress at which a material begins to deform plastically. | Point where permanent deformation starts on the stress-strain curve. | Determines elastic limit and design stress criteria. | Megapascal (MPa) or Pounds per square inch (psi) |

Understanding Tensile Strength and Yield Strength

Tensile strength measures the maximum stress a material can withstand while being stretched before breaking, indicating its ultimate load-bearing capacity. Yield strength represents the stress level at which a material begins to deform plastically, marking the transition from elastic deformation and the point where permanent strain occurs. Understanding both properties is essential for selecting materials that must endure specific mechanical stresses without permanent damage or failure.

Key Differences Between Tensile and Yield Strength

Tensile strength measures the maximum stress a material can withstand while being stretched before breaking, whereas yield strength indicates the stress level at which a material begins to deform plastically. Yield strength is critical for determining the elastic limit of materials in structural applications, while tensile strength defines the ultimate failure point under tension. Understanding their differences helps engineers select appropriate materials for safety and performance in mechanical design.

Importance in Mechanical Engineering Applications

Tensile strength and yield strength are crucial parameters in mechanical engineering for ensuring material reliability under stress. Tensile strength indicates the maximum stress a material can withstand before failure, while yield strength defines the stress at which permanent deformation begins, guiding safe load limits. Understanding both properties is essential for selecting materials that ensure structural integrity and prevent catastrophic mechanical failures in engineering designs.

How Tensile Strength is Measured

Tensile strength is measured by applying a uniaxial force to a specimen using a tensile testing machine until it fractures, recording the maximum stress the material endures. The measurement involves elongating the specimen and monitoring the stress-strain curve to determine the ultimate tensile stress value. This process quantifies the maximum load-bearing capacity before failure, distinguishing tensile strength from yield strength, which marks the onset of permanent deformation.

Yield Strength Testing Methods

Yield strength testing methods primarily include the tensile test, which measures the stress at which a material begins to deform plastically. Techniques such as the offset method (commonly 0.2% strain) are widely used to accurately determine yield strength by identifying the point where permanent deformation starts. Advanced methods like digital image correlation (DIC) provide precise strain measurements, enhancing the reliability of yield strength results in complex materials.

Factors Affecting Tensile and Yield Strength

Material composition, heat treatment processes, and microstructural characteristics significantly influence tensile and yield strength. Grain size refinement generally enhances yield strength through the Hall-Petch relationship, while alloying elements and impurities affect both tensile and yield strengths by altering dislocation movement. Furthermore, manufacturing processes such as cold working and annealing modify the material's internal stress state, directly impacting these mechanical properties.

Material Selection Based on Strength Properties

Tensile strength represents the maximum stress a material can withstand while being stretched before breaking, whereas yield strength indicates the stress at which a material begins to deform plastically. Selecting materials with appropriate tensile and yield strengths is critical for engineering applications requiring balance between elasticity and durability, such as in aerospace or automotive components. High-yield strength materials provide resistance to permanent deformation, while high tensile strength materials ensure failure resistance under extreme loads.

Case Studies: Real-world Applications

Case studies in structural engineering reveal that materials with high tensile strength, like high-strength steel, are preferred for applications requiring resistance to dynamic loads, such as bridges and cranes, while yield strength is critical in components subjected to permanent deformation, like automotive frames and pressure vessels. For instance, the Tacoma Narrows Bridge collapse highlighted the importance of considering yield strength to prevent structural failure under stress. Evaluations of aerospace components demonstrate that optimizing both tensile and yield strength improves safety margins and prolongs service life in extreme environments.

Tensile vs Yield Strength in Failure Analysis

Tensile strength measures the maximum stress a material can withstand before fracturing, while yield strength indicates the stress at which it begins to deform plastically. In failure analysis, comparing tensile strength and yield strength helps identify whether a component failed due to excessive deformation or sudden fracture. Understanding this distinction is critical for diagnosing material behavior and improving design safety margins.

Improving Strength Properties of Materials

Tensile strength measures the maximum stress a material can withstand before failure, while yield strength indicates the stress at which a material begins to deform plastically. Improving strength properties involves alloying, heat treatment, and work hardening techniques to enhance both tensile and yield strengths by refining microstructure and increasing dislocation density. Advanced methods such as nano-scale reinforcement and grain boundary engineering significantly boost these properties, enabling materials to sustain higher loads with minimal deformation.

Elastic limit

The elastic limit defines the maximum stress a material can withstand without permanent deformation, distinguishing the yield strength where plastic deformation begins from the tensile strength representing ultimate failure.

Ultimate tensile strength

Ultimate tensile strength represents the maximum stress a material withstands before fracture, exceeding yield strength, which marks the onset of permanent deformation.

Proportional limit

The proportional limit defines the maximum stress at which a material's tensile strength and yield strength remain linearly related before permanent deformation begins.

Ductility

Tensile strength measures the maximum stress a material withstands before breaking, while yield strength marks the stress at which permanent deformation begins, with higher ductility indicating greater ability to deform plastically before rupture.

Plastic deformation

Tensile strength represents the maximum stress a material can withstand, while yield strength marks the onset of plastic deformation where permanent shape change begins.

Modulus of resilience

Modulus of resilience quantifies the maximum energy per unit volume a material can absorb elastically before yielding, linking tensile strength and yield strength through its measurement of elastic strain energy capacity.

Strain hardening

Strain hardening increases tensile strength by enabling a material to withstand greater stress beyond its initial yield strength through plastic deformation.

Stress-strain curve

The stress-strain curve illustrates that tensile strength represents the maximum stress a material can withstand before necking, while yield strength marks the stress level at which permanent deformation begins.

Necking

Necking occurs after a material reaches its yield strength, leading to localized deformation and a subsequent decrease in tensile strength until fracture.

Fracture point

Fracture point occurs after the tensile strength is surpassed and signifies the material's failure, whereas the yield strength marks the onset of permanent deformation without fracture.

tensile strength vs yield strength Infographic

njnir.com

njnir.com