Vibration damping reduces the amplitude of vibrations by converting kinetic energy into heat or other forms of energy, effectively minimizing motion within a system. In contrast, vibration isolation prevents the transmission of vibrational energy from one part to another by using materials or devices that absorb or block vibrations. Both techniques enhance machinery performance and longevity but serve distinct roles in controlling mechanical vibrations.

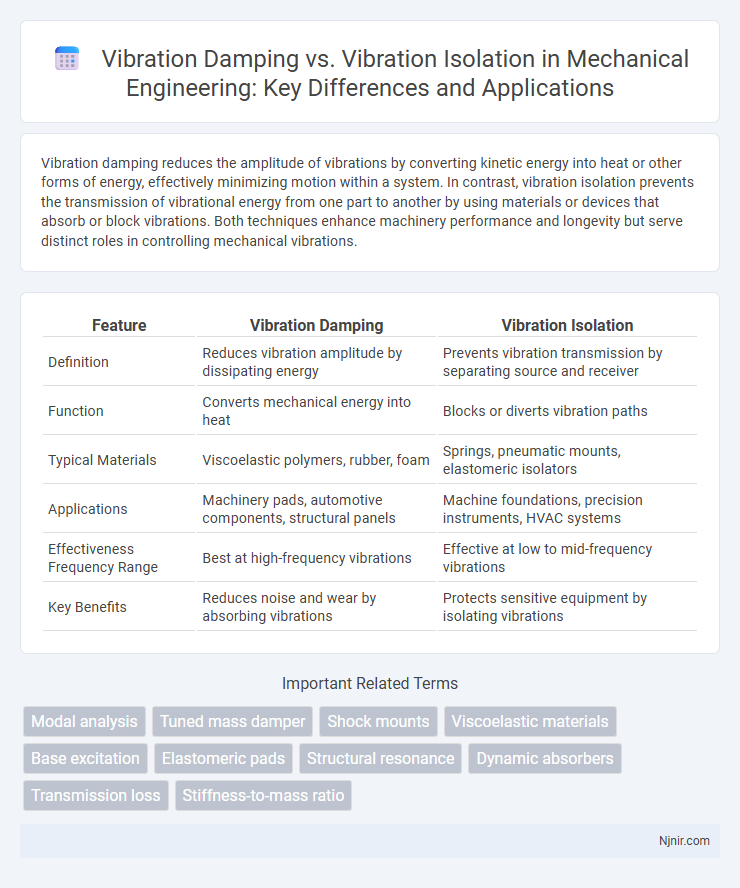

Table of Comparison

| Feature | Vibration Damping | Vibration Isolation |

|---|---|---|

| Definition | Reduces vibration amplitude by dissipating energy | Prevents vibration transmission by separating source and receiver |

| Function | Converts mechanical energy into heat | Blocks or diverts vibration paths |

| Typical Materials | Viscoelastic polymers, rubber, foam | Springs, pneumatic mounts, elastomeric isolators |

| Applications | Machinery pads, automotive components, structural panels | Machine foundations, precision instruments, HVAC systems |

| Effectiveness Frequency Range | Best at high-frequency vibrations | Effective at low to mid-frequency vibrations |

| Key Benefits | Reduces noise and wear by absorbing vibrations | Protects sensitive equipment by isolating vibrations |

Introduction to Vibration Control in Mechanical Engineering

Vibration damping reduces the amplitude of mechanical vibrations by converting vibrational energy into heat, using materials like viscoelastic polymers or mechanical dampers to minimize oscillations in structures and machinery. Vibration isolation involves preventing the transmission of vibration from a source to surrounding structures by employing devices such as springs, elastomer mounts, or pneumatic isolators to decouple vibrations at the interface. In mechanical engineering, effective vibration control combines both damping and isolation techniques to enhance system performance, increase component lifespan, and reduce noise and structural fatigue.

Fundamentals of Vibration Damping

Vibration damping reduces the amplitude of vibrations by converting kinetic energy into heat or other forms of energy, effectively dissipating vibrational energy within a material or structure. It relies on the intrinsic material properties, such as viscoelasticity, to absorb and attenuate vibrations, minimizing resonance effects. Unlike vibration isolation, which aims to prevent the transmission of vibrations to surrounding structures, damping focuses on controlling and reducing vibrations within the system itself.

Fundamentals of Vibration Isolation

Vibration isolation fundamentally involves preventing the transmission of vibration from a source to a sensitive component by introducing barriers such as springs or elastomers, which reduce the energy transfer. The effectiveness of vibration isolation depends on parameters like natural frequency, damping ratio, and transmissibility, with the goal to achieve a natural frequency much lower than the excitation frequency. Unlike vibration damping, which dissipates energy through materials or devices to reduce vibration amplitude, vibration isolation primarily focuses on reducing vibration transmission by strategically decoupling the vibration source and the protected system.

Key Differences: Vibration Damping vs Vibration Isolation

Vibration damping reduces the amplitude of vibrations by converting kinetic energy into heat or other forms of energy within a material, targeting the control of motion within a system. Vibration isolation prevents the transmission of vibrations between two structures by using materials or devices such as rubber mounts or springs to absorb or block vibrational energy. Key differences include damping's role in energy dissipation versus isolation's function as a physical barrier to vibration transfer, with damping influencing internal system dynamics and isolation focusing on external vibration prevention.

Mechanisms and Materials for Vibration Damping

Vibration damping involves dissipating energy through materials such as viscoelastic polymers, elastomers, and constrained layer damping composites that convert mechanical energy into heat, reducing oscillation amplitudes. Mechanisms like material hysteresis and internal friction enable these materials to absorb and attenuate vibrations effectively. In contrast, vibration isolation primarily aims to prevent vibration transmission using mounts, pads, or springs that physically separate the vibrating source from other structures.

Technologies and Devices for Vibration Isolation

Vibration isolation technologies employ devices such as elastomeric mounts, pneumatic isolators, and active isolation systems to minimize the transmission of unwanted vibrations from a source to sensitive equipment or structures. These devices use materials with high damping properties or active feedback mechanisms to absorb or counteract vibrational energy, enhancing precision in applications like semiconductor manufacturing and aerospace testing. Advanced vibration isolation solutions incorporate adaptive control algorithms and smart materials to optimize performance across varying frequencies and load conditions.

Application Areas: Where Damping or Isolation is Preferred

Vibration damping is preferred in applications involving machinery with internal moving parts, such as automotive engines and industrial equipment, where reducing energy dissipation within the system improves performance. Vibration isolation is favored in sensitive environments like precision laboratories and medical imaging facilities, where preventing external vibrations from transmitting to equipment is critical. Both techniques are integral in construction and aerospace sectors, tailoring vibration control to either absorb or block vibrations based on specific operational requirements.

Selection Criteria for Optimal Vibration Control

Selection criteria for optimal vibration control prioritize the frequency range, amplitude, and type of vibration to differentiate between vibration damping and vibration isolation techniques. Vibration damping is most effective for reducing resonant vibrations within structures by dissipating energy, making materials like viscoelastic polymers ideal. Vibration isolation targets decoupling the source from the receiver, often using isolators such as elastomeric mounts or air springs to minimize transmitted vibration across a broad frequency spectrum.

Performance Evaluation and Measurement Techniques

Vibration damping reduces oscillation amplitude within a material or structure by converting kinetic energy into heat, measured through metrics like damping ratio and loss factor using accelerometers and laser vibrometry. Vibration isolation prevents transmission of vibrations by mechanical separation, evaluated by transmissibility and isolation efficiency using frequency response functions (FRF) and modal analysis. Comparative performance evaluation involves analyzing these parameters under controlled environmental and operational conditions to optimize system stability and longevity.

Future Trends in Vibration Damping and Isolation

Future trends in vibration damping and isolation emphasize the integration of smart materials such as piezoelectric and magnetorheological composites that dynamically adjust properties in response to vibration frequencies. Advances in nanotechnology enable the development of lightweight, high-performance damping materials that enhance energy dissipation while maintaining structural integrity. The implementation of IoT-enabled sensors and AI-driven adaptive control systems offers real-time monitoring and optimization, revolutionizing vibration management across automotive, aerospace, and industrial applications.

Modal analysis

Modal analysis distinguishes vibration damping, which reduces energy within vibrating modes, from vibration isolation, which minimizes the transmission of vibration to other structures.

Tuned mass damper

Tuned mass dampers enhance vibration damping by absorbing and dissipating vibrational energy, whereas vibration isolation primarily prevents vibrations from transferring by decoupling structures.

Shock mounts

Shock mounts enhance vibration damping by absorbing energy within the material, while vibration isolation minimizes transmission by physically separating the source from the structure.

Viscoelastic materials

Viscoelastic materials enhance vibration damping by converting mechanical energy into heat, effectively reducing vibrations within structures, whereas vibration isolation uses materials or systems to physically separate and minimize the transmission of vibrations to sensitive components.

Base excitation

Vibration damping reduces base excitation energy by dissipating vibrational forces within a structure, while vibration isolation minimizes base excitation transmission through specialized mounts or materials.

Elastomeric pads

Elastomeric pads enhance vibration control by providing superior vibration damping through energy absorption while also offering effective vibration isolation by reducing the transmission of vibrational energy to surrounding structures.

Structural resonance

Vibration damping reduces structural resonance by absorbing energy within the material, whereas vibration isolation prevents resonance by decoupling the structure from vibration sources.

Dynamic absorbers

Dynamic absorbers enhance vibration damping by targeting specific frequencies to reduce resonant vibrations, whereas vibration isolation minimizes vibration transmission through the use of compliant materials or systems.

Transmission loss

Vibration damping reduces vibration amplitude within a system by converting mechanical energy into heat, while vibration isolation minimizes transmission loss by preventing vibration energy from passing between structures.

Stiffness-to-mass ratio

Vibration damping reduces oscillation amplitude by converting kinetic energy to heat, while vibration isolation minimizes transmitted vibrations through low stiffness-to-mass ratio systems that decouple equipment from vibration sources.

Vibration damping vs vibration isolation Infographic

njnir.com

njnir.com