Ductile fracture involves significant plastic deformation before failure, characterized by a slow crack propagation and a rough fracture surface. Brittle fracture occurs with minimal plastic deformation, resulting in rapid crack propagation and a smooth, shiny fracture surface. Understanding the differences between ductile and brittle fracture is critical for selecting materials and designing components to prevent catastrophic failure.

Table of Comparison

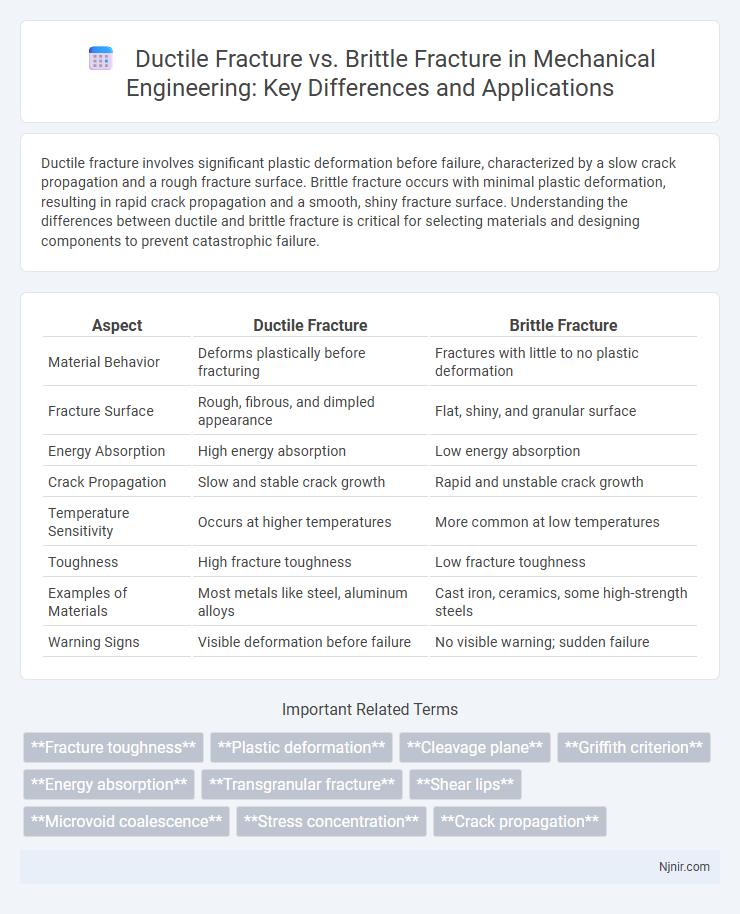

| Aspect | Ductile Fracture | Brittle Fracture |

|---|---|---|

| Material Behavior | Deforms plastically before fracturing | Fractures with little to no plastic deformation |

| Fracture Surface | Rough, fibrous, and dimpled appearance | Flat, shiny, and granular surface |

| Energy Absorption | High energy absorption | Low energy absorption |

| Crack Propagation | Slow and stable crack growth | Rapid and unstable crack growth |

| Temperature Sensitivity | Occurs at higher temperatures | More common at low temperatures |

| Toughness | High fracture toughness | Low fracture toughness |

| Examples of Materials | Most metals like steel, aluminum alloys | Cast iron, ceramics, some high-strength steels |

| Warning Signs | Visible deformation before failure | No visible warning; sudden failure |

Introduction to Ductile and Brittle Fracture

Ductile fracture occurs through significant plastic deformation, characterized by a gradual crack propagation and energy absorption before failure. Brittle fracture involves rapid crack propagation with minimal plastic deformation, leading to sudden and catastrophic failure. Understanding the microstructural mechanisms differentiates ductile materials, which exhibit high toughness, from brittle materials that fail under relatively low strain.

Fundamental Differences Between Ductile and Brittle Fracture

Ductile fracture is characterized by significant plastic deformation before failure, involving micro-void nucleation, growth, and coalescence, which provides energy absorption and resistance to crack propagation. Brittle fracture occurs with minimal plastic deformation, typically along specific crystallographic planes, resulting in rapid crack propagation and low energy absorption. The fundamental difference lies in the material's ability to undergo plastic deformation; ductile materials deform and absorb energy, while brittle materials fracture suddenly under stress.

Microstructural Characteristics of Each Fracture Type

Ductile fracture is characterized by significant plastic deformation with microvoid coalescence and necking, producing a fibrous and rough fracture surface visible under a scanning electron microscope (SEM). Brittle fracture occurs with minimal plastic deformation, featuring cleavage planes, intergranular cracking, or transgranular cracking, often resulting in a flat and shiny fracture surface. Microstructural examination reveals ductile fracture primarily involves microvoid nucleation, growth, and coalescence in ductile metals, while brittle fracture is driven by crack propagation along grain boundaries or crystallographic planes in materials like ceramics or some steels.

Stress-Strain Behavior and Fracture Response

Ductile fracture exhibits significant plastic deformation with a characteristic stress-strain curve showing a pronounced yield point and strain hardening before failure, indicating energy absorption through extensive dislocation movement. Brittle fracture, in contrast, occurs with minimal plastic deformation, demonstrated by a nearly linear elastic stress-strain response up to the point of sudden fracture, reflecting low energy absorption and crack propagation at high stress concentration. The fracture response of ductile materials involves necking and microvoid coalescence, while brittle materials fail via rapid crack initiation and propagation along cleavage planes, resulting in fracture surfaces with a granular, faceted appearance.

Influencing Factors: Temperature, Material Composition, and Strain Rate

Ductile fracture typically occurs at higher temperatures and slower strain rates, where materials exhibit significant plastic deformation before failure, while brittle fracture dominates at low temperatures and high strain rates, causing sudden, catastrophic failure with minimal plastic deformation. Material composition profoundly influences fracture behavior; alloys with face-centered cubic (FCC) crystal structures, like aluminum and copper, tend to show ductile fracture, whereas body-centered cubic (BCC) materials, such as ferritic steels, are more prone to brittle fracture. Variations in alloying elements, impurities, and microstructural features further affect fracture mode by altering toughness, yield strength, and crack propagation resistance.

Fracture Surface Features and Visual Identification

Ductile fracture surfaces exhibit a rough, fibrous texture with numerous microvoid coalescences and dimples, indicating significant plastic deformation prior to failure. In contrast, brittle fracture surfaces appear smooth and shiny with cleavage facets, showing a flat and granular morphology linked to rapid crack propagation without plastic deformation. Visual identification often relies on these surface characteristics: ductile fractures display necking and stretching, whereas brittle fractures reveal sharp crack paths and fracture origins.

Real-World Examples of Ductile and Brittle Failure

Ductile fracture is commonly observed in structural steel used in bridges, where materials undergo significant plastic deformation before failure, preventing sudden collapse. In contrast, brittle fracture is exemplified by the infamous Liberty ships during World War II, which fractured abruptly in cold waters due to low-temperature embrittlement of the hull steel. Understanding the fracture behavior in materials like aluminum alloys in aircraft or cast iron in pipelines helps engineers select appropriate materials to mitigate catastrophic failures in real-world applications.

Testing Methods for Fracture Analysis

Fracture analysis testing methods for ductile fracture commonly involve tensile and Charpy impact tests to evaluate material toughness and plastic deformation before failure, while brittle fracture is often assessed using fracture toughness (K_IC) testing and slow strain rate tests to determine crack propagation resistance. Detailed fractographic analysis through scanning electron microscopy (SEM) provides critical insights into the microstructural features distinguishing ductile dimples from brittle cleavage facets. Combining these methods ensures accurate characterization of fracture behavior under various loading and environmental conditions.

Prevention and Mitigation Strategies

Preventing ductile fracture involves enhancing material toughness through processes like heat treatment and alloying, which improve ductility and energy absorption capacity. Mitigation strategies for brittle fracture focus on reducing stress concentrations and operating temperatures while employing materials with higher fracture toughness and implementing rigorous inspection protocols to detect cracks early. Combining these approaches in design and maintenance minimizes catastrophic failures in structural components.

Implications in Mechanical Engineering Design

Ductile fracture offers higher energy absorption and warning before failure, making it preferable for mechanical engineering designs requiring safety and durability under dynamic loads. Brittle fracture occurs with little deformation and sudden failure, posing significant risks in low-temperature or high-strain-rate applications that demand careful material selection and design considerations to avoid catastrophic failure. Understanding the fracture mode influences material choice, structural integrity assessments, and predictive maintenance strategies in engineering systems.

Fracture toughness

Ductile fracture exhibits higher fracture toughness due to extensive plastic deformation before failure, whereas brittle fracture shows low fracture toughness with sudden crack propagation and minimal plastic deformation.

Plastic deformation

Ductile fracture involves significant plastic deformation before failure, while brittle fracture occurs with minimal or no plastic deformation.

Cleavage plane

Ductile fracture involves extensive plastic deformation without clear cleavage planes, while brittle fracture propagates rapidly along well-defined cleavage planes characterized by low energy absorption.

Griffith criterion

The Griffith criterion quantitatively explains brittle fracture by relating crack propagation to surface energy and stress intensity, while ductile fracture involves significant plastic deformation beyond the Griffith model's assumptions.

Energy absorption

Ductile fracture absorbs significantly more energy through plastic deformation before failure, while brittle fracture absorbs minimal energy due to rapid crack propagation with little plastic deformation.

Transgranular fracture

Transgranular fracture in ductile materials involves crack propagation through grains accompanied by significant plastic deformation, whereas in brittle materials, it occurs with minimal plasticity and rapid crack advancement along grain boundaries.

Shear lips

Shear lips are prominent angled edges formed at the fracture surface in ductile fracture, indicating significant plastic deformation before failure, unlike brittle fracture where shear lips are minimal or absent.

Microvoid coalescence

Microvoid coalescence is the dominant mechanism in ductile fracture characterized by the nucleation, growth, and merging of microvoids leading to significant plastic deformation, contrasting with brittle fracture which involves minimal plasticity and rapid crack propagation.

Stress concentration

Stress concentration significantly influences ductile fracture by promoting plastic deformation around flaws, whereas in brittle fracture it leads to rapid crack propagation with minimal plasticity.

Crack propagation

Ductile fracture exhibits slow, stable crack propagation with significant plastic deformation, while brittle fracture features rapid, unstable crack propagation with minimal plastic deformation.

Ductile fracture vs brittle fracture Infographic

njnir.com

njnir.com