Thermoelectric cooling harnesses the Seebeck effect to create a temperature difference by converting electrical energy into a heat flux, enabling efficient solid-state cooling without moving parts. Peltier cooling, a subset of thermoelectric cooling, specifically relies on the Peltier effect where an electric current drives heat transfer across junctions of different materials, making it ideal for precise temperature control in compact applications. Both methods offer advantages in reliability and maintenance-free operation compared to traditional vapor-compression systems, though Peltier devices often exhibit lower efficiency in large-scale cooling scenarios.

Table of Comparison

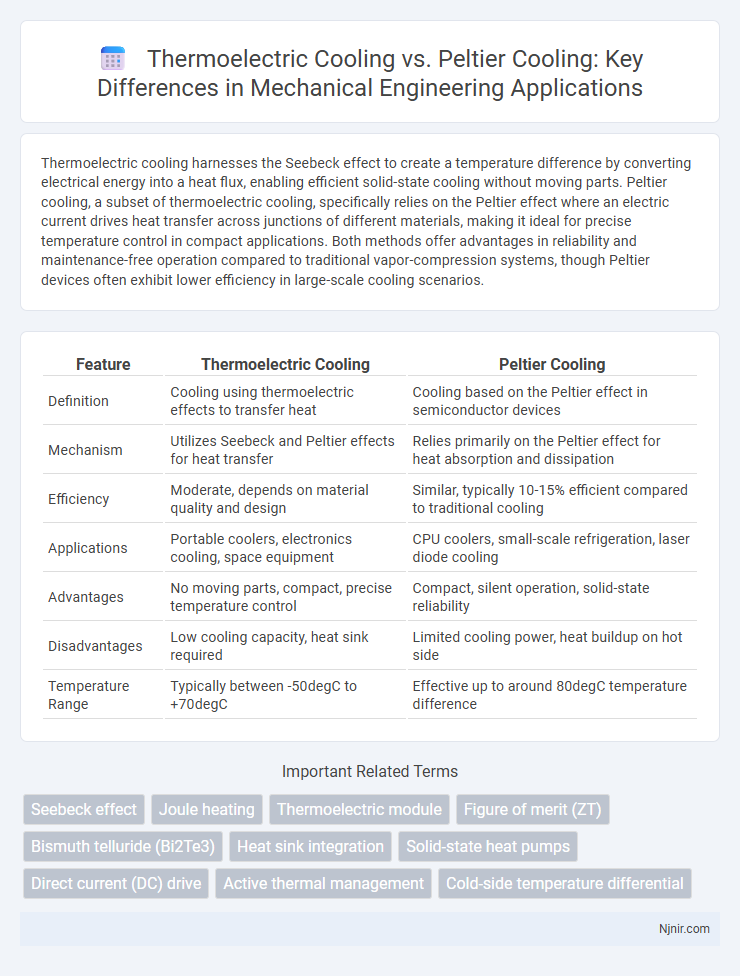

| Feature | Thermoelectric Cooling | Peltier Cooling |

|---|---|---|

| Definition | Cooling using thermoelectric effects to transfer heat | Cooling based on the Peltier effect in semiconductor devices |

| Mechanism | Utilizes Seebeck and Peltier effects for heat transfer | Relies primarily on the Peltier effect for heat absorption and dissipation |

| Efficiency | Moderate, depends on material quality and design | Similar, typically 10-15% efficient compared to traditional cooling |

| Applications | Portable coolers, electronics cooling, space equipment | CPU coolers, small-scale refrigeration, laser diode cooling |

| Advantages | No moving parts, compact, precise temperature control | Compact, silent operation, solid-state reliability |

| Disadvantages | Low cooling capacity, heat sink required | Limited cooling power, heat buildup on hot side |

| Temperature Range | Typically between -50degC to +70degC | Effective up to around 80degC temperature difference |

Introduction to Thermoelectric and Peltier Cooling

Thermoelectric cooling utilizes the Peltier effect, where an electric current passes through two different conductors, generating a heat transfer that cools one side while heating the other. Peltier coolers, or thermoelectric modules, are solid-state devices composed of semiconductor materials designed to provide precise temperature control without moving parts. These systems are widely used in applications requiring compact, reliable, and vibration-free cooling solutions.

Basic Principles of Thermoelectric Cooling

Thermoelectric cooling operates on the Peltier effect, where an electric current passed through the junction of two different conductors causes heat absorption at one side and heat dissipation at the other. This solid-state cooling method offers precise temperature control without moving parts or refrigerants, enhancing reliability and environmental safety. Key components include semiconductor materials that efficiently transfer heat when subjected to electric voltage, enabling compact and maintenance-free cooling solutions.

How Peltier Cooling Works

Peltier cooling operates based on the Peltier effect, where an electric current passed through a junction of two different semiconductors creates a temperature difference, causing one side to absorb heat and cool down while the other side dissipates heat. This solid-state cooling method allows for precise temperature control without moving parts or refrigerants, making it ideal for compact and portable cooling applications. Thermoelectric coolers (TECs), commonly called Peltier coolers, leverage this effect for efficient cooling in electronics, medical devices, and small refrigeration units.

Key Differences Between Thermoelectric and Peltier Cooling

Thermoelectric cooling and Peltier cooling both rely on the Peltier effect, but thermoelectric cooling refers to the broader application of thermoelectric devices for heat transfer, while Peltier cooling specifically denotes the use of Peltier modules for solid-state cooling solutions. Key differences include efficiency levels, where thermoelectric cooling devices are optimized for larger-scale thermal management with improved heat pumping capacity, whereas Peltier coolers are typically preferred for compact, low-power applications due to their simplicity and reliability. Material composition and device configuration also differ, influencing thermal conductivity and electrical resistance, which affect cooling performance and system integration.

Efficiency Comparison: Thermoelectric vs. Peltier Coolers

Thermoelectric coolers, often referred to as Peltier coolers, utilize the Peltier effect to transfer heat, but their efficiency varies based on design and materials. Traditional thermoelectric modules generally exhibit lower Coefficient of Performance (COP), typically around 0.3 to 0.7, compared to vapor-compression systems, with improvements seen in advanced Peltier coolers employing optimized semiconductor materials and multi-stage configurations. Efficiency in thermoelectric cooling hinges on minimizing thermal resistance and maximizing electrical conductivity, making material innovation crucial for narrowing the gap to conventional refrigeration methods.

Applications in Mechanical Engineering

Thermoelectric cooling, widely used in mechanical engineering, exploits the Peltier effect to transfer heat using solid-state devices without moving parts, enabling precise temperature control in compact systems. Peltier coolers are commonly applied in cooling electronic components, temperature regulation in sensors, and thermal management of small-scale machinery due to their reliability and energy efficiency. These cooling devices are integral in developing advanced thermal management solutions in aerospace, automotive systems, and industrial automation where space constraints and rapid thermal response are critical.

Advantages and Disadvantages of Each Technology

Thermoelectric cooling utilizes the Peltier effect to transfer heat efficiently, providing solid-state reliability and compact design with no moving parts, making it ideal for precise temperature control in electronics and small-scale refrigeration. Peltier cooling devices specifically refer to modules based on thermoelectric cooling technology, offering advantages such as quiet operation, lightweight, and environmentally friendly refrigerant-free function, but they suffer from relatively low energy efficiency and limited cooling capacity compared to conventional systems. Both technologies face challenges in heat dissipation and cost-effectiveness, with thermoelectric coolers excelling in maintenance-free durability while Peltier modules are often constrained by thermal resistance and higher power consumption.

Material Selection and Design Considerations

Thermoelectric cooling and Peltier cooling both rely on semiconductor materials, primarily bismuth telluride (Bi2Te3), for efficient heat transfer through the Seebeck and Peltier effects. Material selection focuses on maximizing the figure of merit (ZT), which involves optimizing electrical conductivity, Seebeck coefficient, and thermal conductivity to improve device performance. Design considerations include managing thermal interfaces, minimizing electrical resistance, and ensuring mechanical stability to enhance cooling efficiency and durability.

Performance Challenges and Solutions

Thermoelectric cooling and Peltier cooling both rely on the Peltier effect but differ in application and efficiency. Performance challenges in Peltier cooling include limited heat flux capacity and high electrical resistance leading to thermal inefficiency, which can be mitigated by optimizing module design with advanced semiconductor materials like bismuth telluride and improving heat dissipation through enhanced heat sinks. Thermoelectric cooling faces solutions such as integrating nanostructured materials to increase the figure of merit (ZT) and employing multi-stage configurations for greater temperature differentials, addressing the inherent trade-offs between cooling power and energy consumption.

Future Trends in Thermoelectric and Peltier Cooling Technologies

Thermoelectric cooling and Peltier cooling are advancing through nanomaterial engineering, enhancing efficiency and reducing energy consumption for diverse applications. Emerging trends include integration with renewable energy systems and smart sensors, enabling adaptive thermal management in electronics and automotive industries. Future developments focus on scalable manufacturing and eco-friendly materials to support sustainable and cost-effective thermal solutions.

Seebeck effect

Thermoelectric cooling, based on the Seebeck effect, harnesses temperature differences to generate electrical voltage, while Peltier cooling directly uses electrical current to induce heat transfer at junctions.

Joule heating

Thermoelectric cooling efficiency is often reduced by Joule heating, which is also a critical factor in the performance limitations of Peltier cooling devices.

Thermoelectric module

Thermoelectric modules utilize the Peltier effect to provide efficient, solid-state cooling without moving parts, making them ideal for precise temperature control in electronics and small-scale refrigeration.

Figure of merit (ZT)

Thermoelectric cooling and Peltier cooling both rely on the Figure of Merit (ZT), where higher ZT values indicate more efficient heat transfer and improved cooling performance in thermoelectric materials.

Bismuth telluride (Bi2Te3)

Bismuth telluride (Bi2Te3) is the most efficient thermoelectric material used in Peltier cooling devices, enabling solid-state heat transfer with high performance and reliability.

Heat sink integration

Thermoelectric cooling relies on Peltier modules whose efficiency is maximized by integrating heat sinks with optimal thermal conductivity and surface area to effectively dissipate heat and maintain temperature stability.

Solid-state heat pumps

Thermoelectric cooling, based on solid-state heat pump principles, utilizes the Peltier effect to directly convert electric current into a temperature gradient, offering efficient, compact, and reliable cooling without moving parts.

Direct current (DC) drive

Thermoelectric cooling employs Peltier modules powered by direct current (DC) to achieve precise temperature control through the Peltier effect, making DC drive essential for efficient thermoelectric device operation.

Active thermal management

Thermoelectric cooling using Peltier devices enables precise active thermal management by converting electrical energy directly into a temperature gradient for efficient heat transfer.

Cold-side temperature differential

Thermoelectric cooling and Peltier cooling both utilize the Peltier effect, but thermoelectric cooling systems often achieve a greater cold-side temperature differential due to improved materials and heat dissipation techniques.

Thermoelectric cooling vs Peltier cooling Infographic

njnir.com

njnir.com