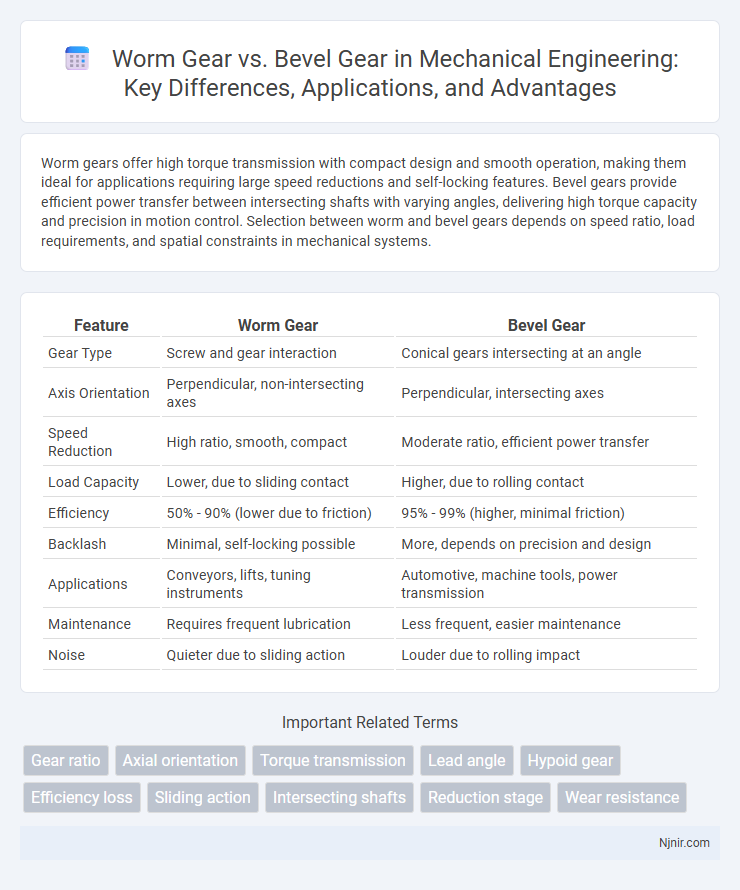

Worm gears offer high torque transmission with compact design and smooth operation, making them ideal for applications requiring large speed reductions and self-locking features. Bevel gears provide efficient power transfer between intersecting shafts with varying angles, delivering high torque capacity and precision in motion control. Selection between worm and bevel gears depends on speed ratio, load requirements, and spatial constraints in mechanical systems.

Table of Comparison

| Feature | Worm Gear | Bevel Gear |

|---|---|---|

| Gear Type | Screw and gear interaction | Conical gears intersecting at an angle |

| Axis Orientation | Perpendicular, non-intersecting axes | Perpendicular, intersecting axes |

| Speed Reduction | High ratio, smooth, compact | Moderate ratio, efficient power transfer |

| Load Capacity | Lower, due to sliding contact | Higher, due to rolling contact |

| Efficiency | 50% - 90% (lower due to friction) | 95% - 99% (higher, minimal friction) |

| Backlash | Minimal, self-locking possible | More, depends on precision and design |

| Applications | Conveyors, lifts, tuning instruments | Automotive, machine tools, power transmission |

| Maintenance | Requires frequent lubrication | Less frequent, easier maintenance |

| Noise | Quieter due to sliding action | Louder due to rolling impact |

Introduction to Worm Gears and Bevel Gears

Worm gears consist of a screw-like worm that meshes with a worm wheel and are primarily used for high reduction ratios and torque transmission in compact spaces. Bevel gears feature conically shaped teeth and are ideal for transferring motion between intersecting shafts, typically at right angles. Both gear types serve distinct mechanical roles in machinery, optimizing power transmission and directional control.

Design Principles of Worm Gears

Worm gears are characterized by a screw-like worm meshing with a toothed wheel, enabling high gear reduction and smooth, quiet operation through sliding contact. Their design principles emphasize axial load capacity, self-locking ability, and compactness, making them ideal for applications requiring precise speed control and torque transmission. Unlike bevel gears, worm gears handle misalignment better and provide greater reduction ratios in a single stage.

Design Principles of Bevel Gears

Bevel gears are designed with conically shaped surfaces where gear teeth are cut along the cone's pitch surface, enabling the transfer of motion between intersecting shafts typically at right angles. Their design principles emphasize precise tooth geometry, such as spiral or straight tooth profiles, to optimize load distribution and reduce noise and vibration during operation. Unlike worm gears, bevel gears rely on direct tooth engagement without sliding friction, resulting in higher efficiency and smoother torque transmission.

Efficiency Comparison: Worm Gear vs Bevel Gear

Worm gears typically exhibit lower efficiency, ranging from 40% to 90%, due to high sliding friction between the worm and the gear, causing greater heat generation and energy loss. Bevel gears generally achieve higher efficiency, often between 95% and 98%, as they rely on rolling contact which reduces friction and power dissipation. The efficiency difference makes bevel gears preferable in applications requiring minimal energy loss, while worm gears are suited for high reduction ratios and load-holding capabilities despite lower efficiency.

Load Capacity and Strength Analysis

Worm gears exhibit high load capacity due to their large contact area and sliding action, making them suitable for heavy-duty applications requiring smooth, quiet operation. Bevel gears provide greater strength and efficiency with rolling contact, handling higher torque loads and shock loads more effectively than worm gears. Strength analysis reveals bevel gears maintain better mechanical advantage and durability under dynamic loads, while worm gears are limited by higher friction and heat generation.

Applications in Mechanical Systems

Worm gears are commonly used in applications requiring high torque and compact design, such as conveyor systems, elevators, and tuning mechanisms in musical instruments, due to their ability to provide substantial speed reduction and self-locking capabilities. Bevel gears are ideal for transmitting power between intersecting shafts, frequently found in automotive differentials, industrial machinery, and marine drives where efficient angular power transmission is essential. Both gear types are selected based on load capacity, speed requirements, and spatial constraints in complex mechanical systems.

Lubrication and Maintenance Requirements

Worm gears require specialized lubrication with high-viscosity oils containing additives to prevent heat buildup and wear due to sliding contact, demanding regular monitoring and oil changes to maintain efficiency. Bevel gears generally use lower-viscosity lubricants, such as gear oils or grease, benefiting from rolling contact that reduces friction and extends maintenance intervals. Effective lubrication is crucial for worm gears to prevent premature failure, while bevel gears typically have lower maintenance costs and easier lubrication access.

Noise and Vibration Characteristics

Worm gears generally produce less noise and vibration due to their sliding contact and continuous engagement, which results in smoother operation compared to bevel gears. Bevel gears, with their rolling contact and angular gear tooth alignment, can generate higher noise levels and vibrations, especially under heavy loads or misalignment conditions. Noise reduction in worm gears is further enhanced by their inherent damping capability, making them suitable for applications requiring quiet performance.

Cost Considerations and Lifecycle

Worm gears generally have lower upfront costs due to simpler manufacturing but may incur higher maintenance expenses over time because of faster wear and lower efficiency. Bevel gears typically require a higher initial investment but offer better durability and longer lifecycle, reducing long-term replacement costs. Evaluating total cost of ownership involves balancing worm gear affordability against bevel gear longevity and performance efficiency.

Choosing Between Worm and Bevel Gears: Key Factors

Worm gears provide high torque and smooth, quiet operation, making them ideal for applications requiring significant speed reduction and load handling, while bevel gears offer efficient power transfer between intersecting shafts with higher speed capabilities. The choice depends on factors such as torque requirements, shaft orientation, efficiency needs, and space constraints. Selecting between worm and bevel gears involves evaluating load capacity, mechanical efficiency, and maintenance considerations to optimize performance in specific industrial applications.

Gear ratio

Worm gears achieve higher gear ratios, often exceeding 100:1, enabling significant speed reduction and increased torque, while bevel gears typically provide lower gear ratios ranging from 1:1 to 6:1, suitable for changing rotational direction with moderate speed adjustment.

Axial orientation

Worm gears feature perpendicular axial orientation with the worm shaft aligned axially to the worm wheel, while bevel gears have intersecting axial orientations, typically at a 90-degree angle.

Torque transmission

Worm gears offer high torque transmission with compact design and smooth operation but lower efficiency, while bevel gears provide efficient torque transfer at varying angles with higher speed capability.

Lead angle

Worm gears have a lead angle typically between 2deg and 30deg, enabling high reduction ratios and smooth, quiet operation, while bevel gears possess larger lead angles that facilitate angular motion transfer with greater torque capacity and efficiency.

Hypoid gear

Hypoid gears, designed with skewed axes and curved teeth, offer higher torque capacity and smoother operation than traditional worm and bevel gears, making them ideal for automotive differentials and heavy machinery applications.

Efficiency loss

Worm gears exhibit significantly higher efficiency loss, often ranging from 40% to 60%, due to increased sliding friction compared to bevel gears, which typically maintain efficiency levels above 90% with predominantly rolling contact.

Sliding action

Worm gears exhibit continuous sliding action between the worm and gear teeth, resulting in smoother operation but higher friction and wear compared to bevel gears, which primarily engage in rolling contact with reduced sliding.

Intersecting shafts

Bevel gears are designed for intersecting shafts, allowing smooth angular motion transmission, whereas worm gears operate with non-intersecting, perpendicular shafts for high torque and speed reduction.

Reduction stage

Worm gears provide high reduction ratios with compact design and smooth operation ideal for low-speed, high-torque applications, while bevel gears offer efficient power transmission at moderate reduction stages with angular shaft configurations.

Wear resistance

Worm gears exhibit higher wear resistance due to their sliding contact and self-lubricating properties, while bevel gears experience increased wear from rolling contact under high load conditions.

Worm gear vs bevel gear Infographic

njnir.com

njnir.com