Mechatronics integrates mechanical engineering with electronics and computer control, enabling precise automation and enhanced system adaptability compared to traditional mechanical systems. Traditional mechanical systems rely primarily on mechanical components and manual control, limiting their flexibility and real-time responsiveness. The fusion of sensors, actuators, and microcontrollers in mechatronics significantly improves performance, maintenance, and efficiency in modern engineering applications.

Table of Comparison

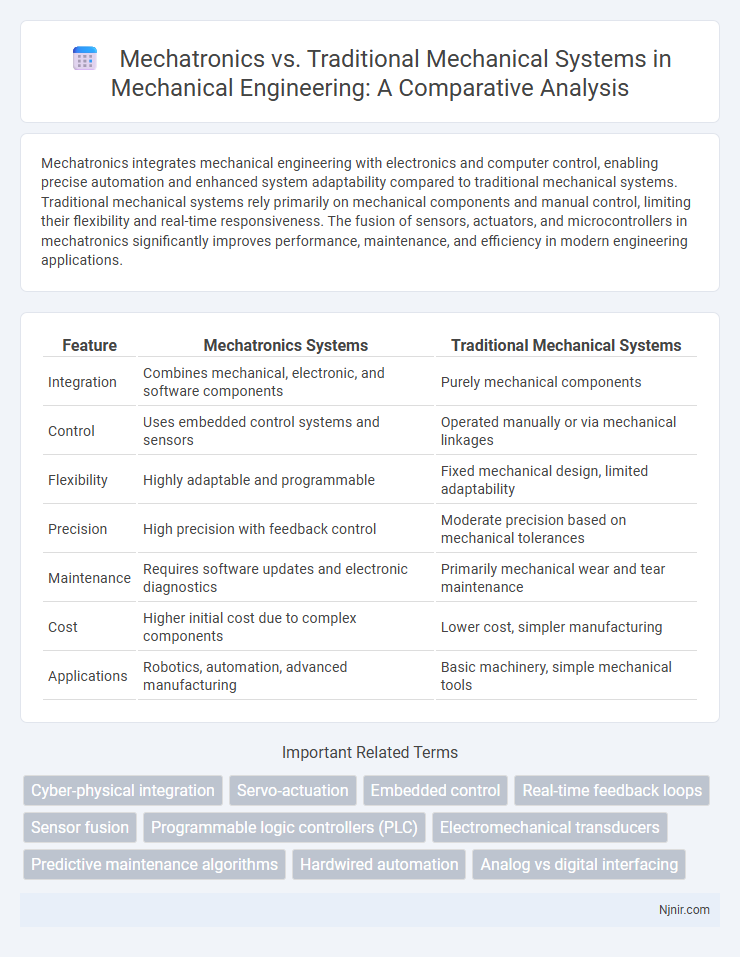

| Feature | Mechatronics Systems | Traditional Mechanical Systems |

|---|---|---|

| Integration | Combines mechanical, electronic, and software components | Purely mechanical components |

| Control | Uses embedded control systems and sensors | Operated manually or via mechanical linkages |

| Flexibility | Highly adaptable and programmable | Fixed mechanical design, limited adaptability |

| Precision | High precision with feedback control | Moderate precision based on mechanical tolerances |

| Maintenance | Requires software updates and electronic diagnostics | Primarily mechanical wear and tear maintenance |

| Cost | Higher initial cost due to complex components | Lower cost, simpler manufacturing |

| Applications | Robotics, automation, advanced manufacturing | Basic machinery, simple mechanical tools |

Introduction to Mechatronics and Traditional Mechanical Systems

Mechatronics integrates mechanical engineering, electronics, computer science, and control engineering to create smart systems capable of automated and precise operations, enhancing functionality beyond traditional mechanical systems. Traditional mechanical systems rely solely on mechanical components and manual control, limiting adaptability and efficiency in complex tasks. The introduction of mechatronics enables advanced diagnostics, real-time monitoring, and adaptive control, revolutionizing how mechanical systems are designed, operated, and maintained.

Core Components: Mechatronics vs. Traditional Approaches

Mechatronics systems integrate sensors, actuators, microcontrollers, and software to enable precise control and adaptability, contrasting with traditional mechanical systems that rely on purely mechanical components like gears, cams, and levers for operation. The core components of mechatronics promote automation and real-time feedback, enhancing performance and flexibility beyond the fixed functionalities of conventional mechanical parts. This integration results in smarter, more efficient systems widely used in robotics, manufacturing, and automotive industries.

Design Principles: Integrating Electronics and Mechanics

Mechatronics design principles emphasize the seamless integration of electronic control systems with mechanical components, enhancing precision, adaptability, and functionality beyond traditional mechanical systems. Traditional mechanical systems rely predominantly on rigid mechanical structures and manual control, limiting responsiveness and automation capabilities. By combining sensors, actuators, and microcontrollers, mechatronics enables dynamic feedback and intelligent behavior, revolutionizing system design and performance.

System Performance and Efficiency Comparison

Mechatronics systems integrate mechanical components with electronic controls and software, resulting in significantly enhanced system performance and operational efficiency compared to traditional mechanical systems. These systems offer precise motion control, adaptive feedback mechanisms, and real-time diagnostics, enabling higher accuracy, reduced energy consumption, and lower maintenance costs. Traditional mechanical systems, dominated by purely mechanical components, often face limitations in responsiveness and efficiency due to lack of automation and smart control integration.

Flexibility and Adaptability in Modern Applications

Mechatronics integrates mechanical systems with electronics and intelligent control, offering superior flexibility and adaptability compared to traditional mechanical systems. This integration enables real-time adjustments, enhanced precision, and seamless interaction with digital interfaces in modern applications such as robotics, automation, and smart manufacturing. Traditional mechanical systems, while robust, lack the dynamic responsiveness required for complex, rapidly changing environments.

Maintenance, Diagnostics, and Troubleshooting

Mechatronics systems integrate electronic sensors and computer controls with mechanical components, enabling predictive maintenance and real-time diagnostics that reduce downtime and enhance troubleshooting efficiency. Traditional mechanical systems rely predominantly on manual inspections and reactive maintenance, which often results in longer downtime and less precise fault identification. The synergy of electronics and software in mechatronics allows for automated fault detection and more accurate maintenance scheduling compared to conventional mechanical systems.

Cost Implications: Initial Investment vs. Long-Term Savings

Mechatronics systems often require a higher initial investment due to advanced sensors, actuators, and control components compared to traditional mechanical systems, which rely on simpler mechanical parts with lower upfront costs. However, mechatronics provides significant long-term savings through enhanced precision, reduced maintenance, and increased operational efficiency, leading to lower downtime and energy consumption. In contrast, traditional mechanical systems may incur higher ongoing expenses due to frequent repairs and less efficient performance.

Industry Adoption and Real-World Examples

Mechatronics integrates mechanical engineering, electronics, and computer control, enabling advanced automation and precision that traditional mechanical systems lack, driving widespread adoption in industries such as automotive manufacturing, robotics, and aerospace. Companies like Tesla utilize mechatronic systems for electric vehicle performance optimization, while traditional mechanical systems remain prevalent in heavy machinery and basic manufacturing due to lower upfront costs. The real-world shift towards Industry 4.0 and smart factories highlights mechatronics as essential for predictive maintenance, IoT integration, and enhanced operational efficiency.

Impact on Workforce Skills and Education

Mechatronics integrates electronics, computer control, and mechanical engineering, demanding a workforce skilled in multidisciplinary knowledge including programming, robotics, and systems integration, which shifts education towards STEM-centric curricula and continuous upskilling. Traditional mechanical systems emphasize mechanical design and manual fabrication skills, often resulting in a workforce focused on hands-on mechanical expertise and vocational training. The transition to mechatronics challenges educational institutions to update programs, fostering competencies in automation and digital technologies essential for modern manufacturing and maintenance roles.

Future Trends in Mechanical System Development

Mechatronics integrates mechanical, electronic, and software components to create more intelligent and adaptive mechanical systems, surpassing traditional mechanical systems that rely solely on mechanical components. Future trends in mechanical system development emphasize increased automation, integration of IoT sensors, and the use of artificial intelligence for predictive maintenance and real-time system optimization. These advancements enable more efficient, reliable, and flexible mechanical systems tailored to Industry 4.0 and smart manufacturing environments.

Cyber-physical integration

Mechatronics systems outperform traditional mechanical systems by seamlessly integrating cyber-physical components for real-time sensing, control, and automation, enhancing precision and efficiency.

Servo-actuation

Servo-actuation in mechatronics enhances precision, responsiveness, and control compared to traditional mechanical systems by integrating sensors and programmable controllers.

Embedded control

Embedded control in mechatronics systems integrates sensors, actuators, and microcontrollers to enable real-time adaptive performance, outperforming traditional mechanical systems reliant solely on passive mechanical components.

Real-time feedback loops

Mechatronics systems integrate real-time feedback loops through sensors and controllers for dynamic adjustments, enhancing precision and efficiency beyond the delayed response mechanisms in traditional mechanical systems.

Sensor fusion

Sensor fusion in mechatronics integrates multiple sensor data to enhance system accuracy and responsiveness beyond the capabilities of traditional mechanical systems.

Programmable logic controllers (PLC)

Programmable Logic Controllers (PLCs) in mechatronics enable real-time automation and precise control, outperforming traditional mechanical systems with fixed, manual operations.

Electromechanical transducers

Electromechanical transducers in mechatronics integrate sensors and actuators for precise control and feedback, whereas traditional mechanical systems rely on purely mechanical transduction methods with limited responsiveness and adaptability.

Predictive maintenance algorithms

Predictive maintenance algorithms in mechatronics leverage sensor data and machine learning to optimize system reliability and reduce downtime, outperforming traditional mechanical systems that rely on scheduled or reactive maintenance.

Hardwired automation

Hardwired automation in traditional mechanical systems relies on fixed, pre-wired control circuits, whereas mechatronics integrates programmable electronics and sensors for flexible, adaptive system control.

Analog vs digital interfacing

Mechatronics systems integrate digital interfacing with sensors and microcontrollers for precise control, whereas traditional mechanical systems rely primarily on analog interfacing with manual or mechanical feedback mechanisms.

Mechatronics vs Traditional mechanical systems Infographic

njnir.com

njnir.com